Torque converter pump

All our parts have a story behind them. Explore sample parts below to uncover applications, materials, technology and geometrical fittings that might be right for your next project.

Torque converter pump

Torque converter cover. Three mounting nuts welded to cover for mounting of flywheel ring gear.

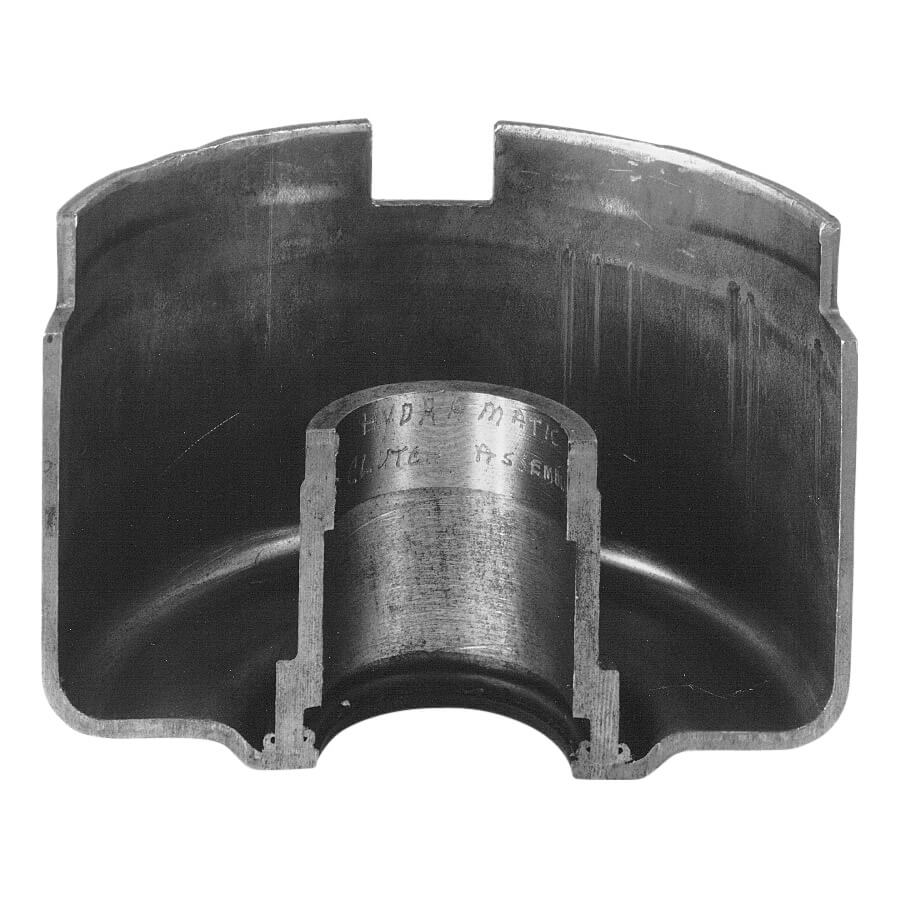

Figure 2 of 2 Direct clutch drum and hub assembly cross-section.

Figure 1 of 2 Direct clutch drum and hub assembly used in automatic transmissions. Mild steel tubing welded to cold-formed clutch drum. Cross-section.

Electric motor housing and shaft for automotive cooling fan.

Automotive transmission component. Machined tubing welded to cold-formed end.

Rear axle housing tube. Forged tube end welded to tube stock.

Automotive axle tube

Water pump hub and shaft

Steering shaft welded to pre-assembled knuckle

Universal joint assembly with welded extension shaft

MTI UK

MTI UK  FWT

FWT