Robust Joining for the Armed Services

Friction Welding for Defense Applications

Fortify Defense with Advanced Friction Welding Technology

The country’s defense faces the challenge of giving the armed forces a strategic advantage. From bi-metallic titanium rivets for aircraft to jet engines, smoke rounds to penetration bombs, and Apache helicopter drive shafts to nuclear bomb cases, MTI’s friction welding process is a proven, solid-state joining solution that helps toughen our defense.

Friction welding holds the answer to integrating technological advancements into state-of-the-art defense structures. Versatile alloys like aluminum give strength while being lightweight metals. Friction welding allows these materials to join without losing their molecular integrity, providing high-strength welds.

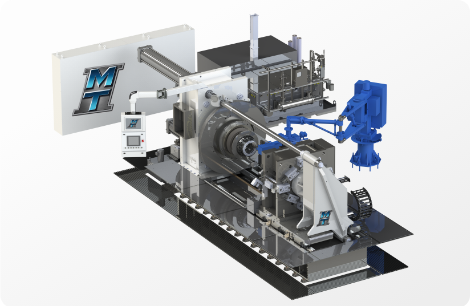

MTI’s Model 400 Rotary friction welder, the largest contract Inertia machine in the world housed at our Manufacturing Services facility.

Advantages & Benefits

Fortifying National Security with Advanced Welding Solutions

MTI’s friction welding technologies are at the forefront of innovation in defense manufacturing. Our cutting-edge solutions deliver unmatched precision, reliability, and performance, empowering the defense industry to create stronger, lighter, and more efficient equipment for protecting our nation’s interests.

Repeatable, Mechanical Process

Defense-related components and products must be consistently safe and reliable when our country needs them. As a mechanical process, friction welding is highly repeatable, resulting from predetermined calculations and measurements that ensure each weld is forged of consistent, high-quality.

Strong Welds

Friction welding is a solid-state process where, unlike fusion methods, does not melt the materials being joined. Instead, the materials are brought to a plasticized state, allowing them to seamlessly forge together while retaining the parent material properties. With forged welding properties, friction welding fortifies any defense application.

Lightweighting

Lightweighting benefits the defense industry by reducing the weight of military vehicles and equipment, enhancing mobility and fuel efficiency. The strong, reliable joints created by friction welding allow for the use of advanced lightweight materials without compromising structural integrity. This improves performance and operational range while lowering transportation and deployment costs. Additionally, lighter equipment can improve maneuverability and speed, providing tactical advantages in the field.

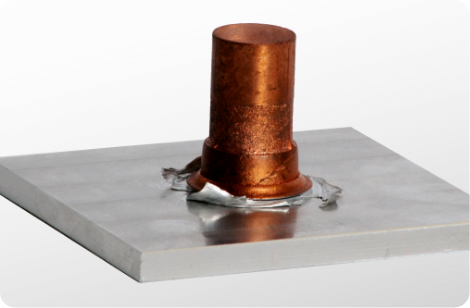

Bimetallic Joining

Bimetallic joining is beneficial for the defense industry because it enables the combination of different materials with complementary properties, such as strength and corrosion resistance. This allows for the creation of specialized components that can withstand harsh environmental conditions. The solid-state nature of friction welding ensures strong, reliable joints without compromising the integrity of the materials, crucial for defense applications where durability and performance are paramount.

Defense-related components and products must be consistently safe and reliable when our country needs them. As a mechanical process, friction welding is highly repeatable, resulting from predetermined calculations and measurements that ensure each weld is forged of consistent, high-quality.

Friction welding is a solid-state process where, unlike fusion methods, does not melt the materials being joined. Instead, the materials are brought to a plasticized state, allowing them to seamlessly forge together while retaining the parent material properties. With forged welding properties, friction welding fortifies any defense application.

Lightweighting benefits the defense industry by reducing the weight of military vehicles and equipment, enhancing mobility and fuel efficiency. The strong, reliable joints created by friction welding allow for the use of advanced lightweight materials without compromising structural integrity. This improves performance and operational range while lowering transportation and deployment costs. Additionally, lighter equipment can improve maneuverability and speed, providing tactical advantages in the field.

Bimetallic joining is beneficial for the defense industry because it enables the combination of different materials with complementary properties, such as strength and corrosion resistance. This allows for the creation of specialized components that can withstand harsh environmental conditions. The solid-state nature of friction welding ensures strong, reliable joints without compromising the integrity of the materials, crucial for defense applications where durability and performance are paramount.

Our Commitment

Commitment to Quality, Dedication to Perfection

MTI brings the highest possible degree of safety and quality, whether it’s a part we’re welding or a machine we’re building. We are equipped to produce parts for the most sensitive environments and exacting standards.

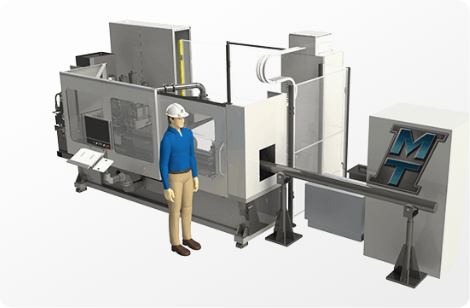

Friction Welding Machines for the Defense Industry

The advantage of machine-welded parts and structures is the perpetual quality of production. Friction welding machines offer more precision, a faster production rate, and fewer errors, leading to economic efficiency.

MTI is NADCAP-accredited, ISO 9001-certified, AS9100-registered, ITAR-compliant, and has been a trusted partner to the defense industry for decades. We are here to collaborate with you on joining defense components or designing and building friction welding machines for your defense needs.

Friction Welding Machines for the Defense Industry

The advantage of machine-welded parts and structures is the perpetual quality of production. Friction welding machines offer more precision, a faster production rate, and fewer errors, leading to economic efficiency.

MTI is NADCAP-accredited, ISO 9001-certified, AS9100-registered, ITAR-compliant, and has been a trusted partner to the defense industry for decades. We are here to collaborate with you on joining defense components or designing and building friction welding machines for your defense needs.

ROTARY FRICTION WELDING

Defense industry engine manufacturers trust MTI-built friction welders for critical armored vehicle components.

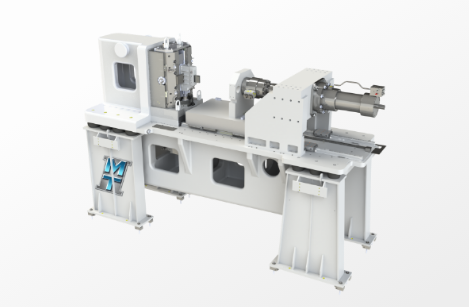

LOW FORCE FRICTION WELDING

MTI Low Force Friction Welding provides cost savings for defense industry applications with reduced flash formation, broader range parts, and quicker cycle times.

LINEAR FRICTION WELDING

The MTI-built LF35-75 allows you to build the largest full-scale bimetallic parts for all your defense industry needs.

FRICTION STIR WELDING

MTI is the trusted service for friction stir welding of stiffened panels for armored vehicles and cold plates in defense systems.

PLUG WELDING

MTI improves the lifespan of components and defense efficiency through plug welding for maintenance and repairs.

Explore Our Sample Parts

Are you wondering if the materials and shapes you have in mind will work for defense applications? Examine our samples to find the materials, uses, and geometric fittings necessary for your next defense project.

Contract Manufacturing Services

Have an idea for a defense project? MTI provides consulting, testing, and manufacturing. We collaborate with clients to develop and create their friction welding machines or parts. We also handle their project for them. We’ll have everything you need to be successful in your project.

Contract Manufacturing Services

Have an idea for a defense project? MTI provides consulting, testing, and manufacturing. We collaborate with clients to develop and create their friction welding machines or parts. We also handle their project for them. We’ll have everything you need to be successful in your project.

Friction Welding Machines for R&D

We Have the Machines to Toughen Your Defense

Research and development is essential to giving defense a strategic advantage. Forge new defenses by testing design and materials with our in-house friction welding machines.

A closer look at MTI’s LF35-75 Linear friction welding machine capable of full-scale development and production.

Learning Center

Case Studies

Videos

Get the information you need, before you need it — free and straight to your inbox from industry experts.