Leave Consumers Wondering, “How Did

They Assemble That?”

Friction Welding for Consumer Products

Make Your Product Stand Out

Friction Welding improves aesthetics, strength, and cost savings. MTI can build the machine that makes the parts you need, or we’ll produce them for you. We offer a full range of services to ensure your machine continues to run optimally.

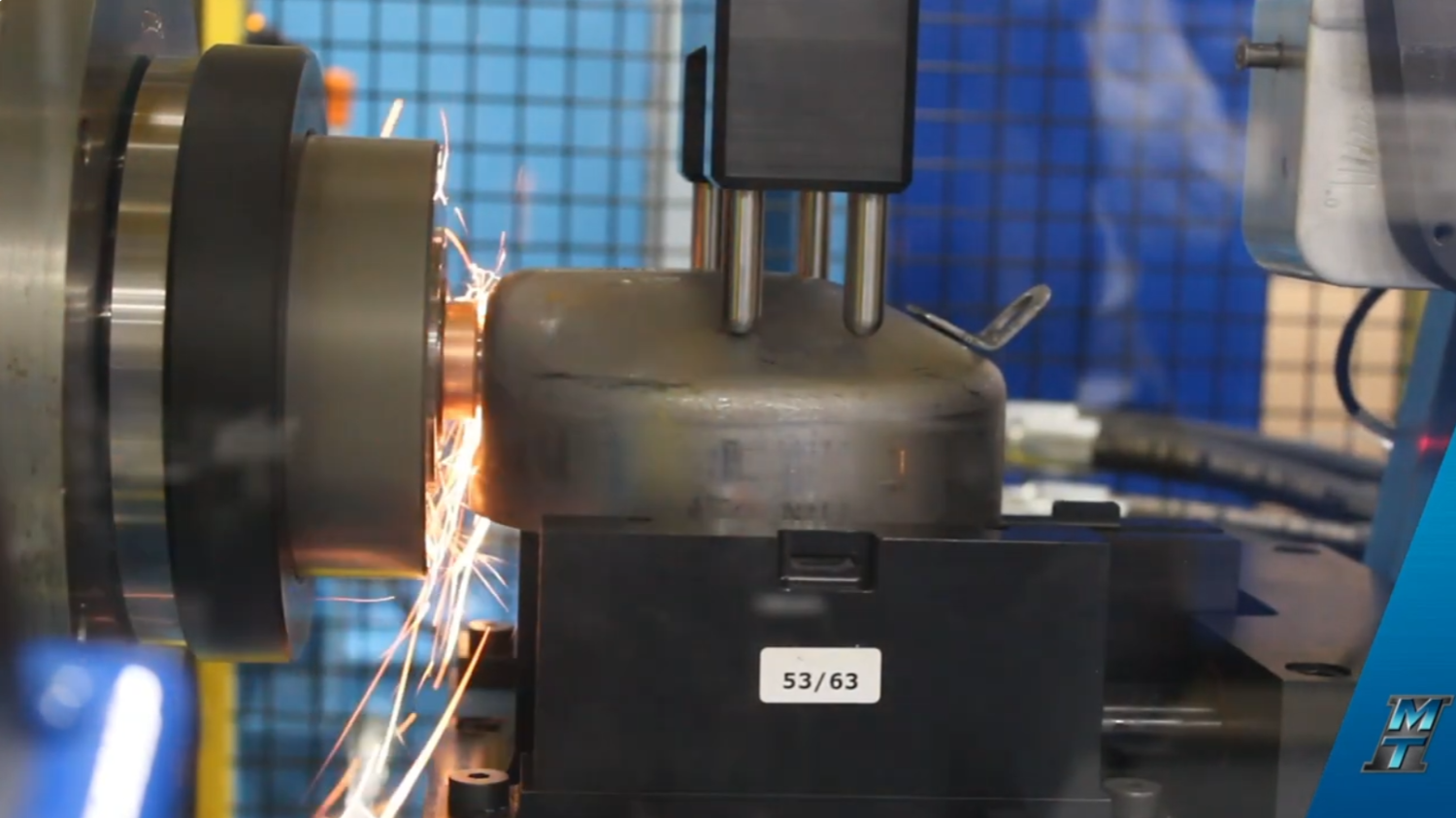

Video courtesy of Rogue Fitness. Video shows an MTI friction welder producing Rogue Fitness barbell sleeves.

Advantages & Benefits

Elevating Consumer Products with Precision and Efficiency

MTI’s friction welding technologies are setting new standards in consumer product manufacturing. Our innovative solutions offer a perfect blend of speed, sustainability, and quality, enabling manufacturers to meet high-volume demands while delivering superior products to consumers.

Fast, Automated Process

Consumer products are often made in large batches, requiring a joining technique that can keep up with the increasing volumes and pace. Friction welding is a mechanically-controlled process that reduces the cycle time required to create a strong bond. Additionally, our friction welding cells can be built with robots and gantry systems, delivering a fully automated process for seamless production.

Green Technology

Friction welding is an eco-friendly technology that does not emit smoke, fumes, or gases. Friction welding does not require consumables such as flux or filler material, reducing your carbon footprint all the way down your supply chain as less material and energy is used.

Smooth, Clean Welds

Friction welding delivers smooth, clean welds for the consumer products industry by using a solid-state process that avoids melting, thus preventing defects like porosity and contamination. This results in aesthetically pleasing and structurally sound joints, which are crucial for the quality and durability of consumer goods. The process also reduces the need for post-weld finishing, saving time and costs. These benefits enhance product reliability and customer satisfaction, giving manufacturers a competitive edge.

Consumer products are often made in large batches, requiring a joining technique that can keep up with the increasing volumes and pace. Friction welding is a mechanically-controlled process that reduces the cycle time required to create a strong bond. Additionally, our friction welding cells can be built with robots and gantry systems, delivering a fully automated process for seamless production.

Friction welding is an eco-friendly technology that does not emit smoke, fumes, or gases. Friction welding does not require consumables such as flux or filler material, reducing your carbon footprint all the way down your supply chain as less material and energy is used.

Friction welding delivers smooth, clean welds for the consumer products industry by using a solid-state process that avoids melting, thus preventing defects like porosity and contamination. This results in aesthetically pleasing and structurally sound joints, which are crucial for the quality and durability of consumer goods. The process also reduces the need for post-weld finishing, saving time and costs. These benefits enhance product reliability and customer satisfaction, giving manufacturers a competitive edge.

Our Commitment

Quality You Can Trust, Precision You Can Rely On

MTI brings the highest possible degree of safety and quality, whether it’s a part we’re welding or a machine we’re building. We are equipped to produce parts for the most sensitive environments and exacting standards.

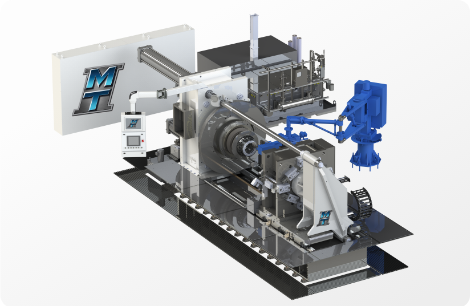

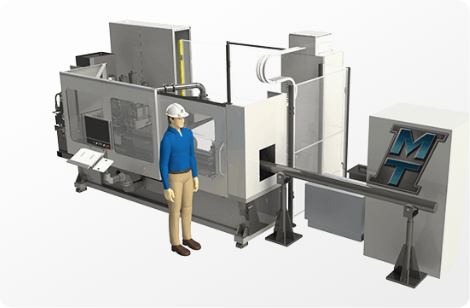

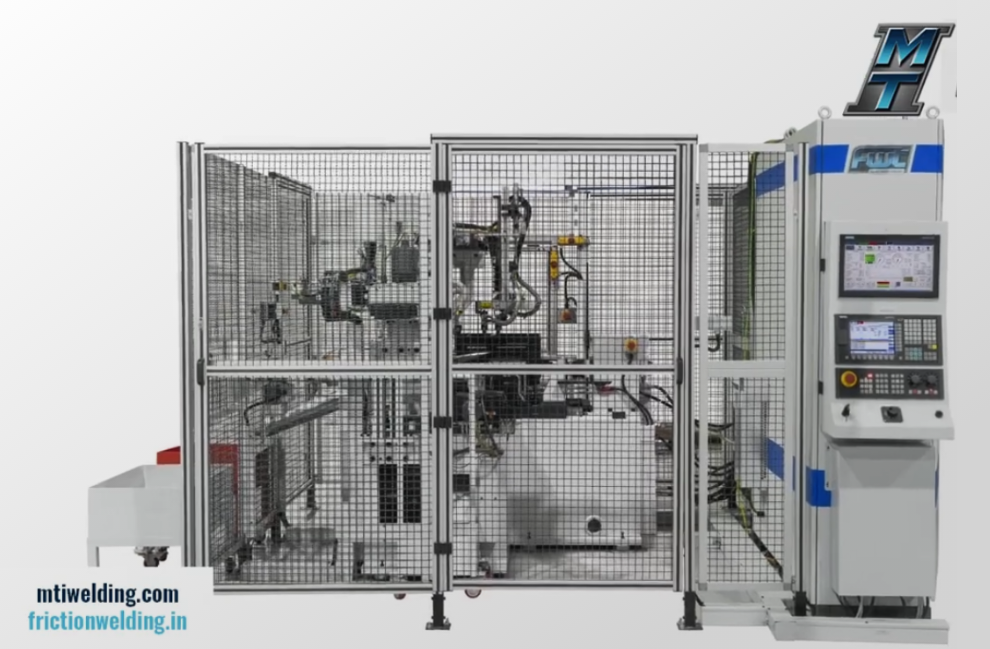

Friction Welding Machines for Consumer Products

Machine-welded parts and products mean fewer errors and more savings. They boast cleaner aesthetics and improved strength, joining metals incompatible with traditional welding.

There is a reason why MTI-built friction welders are still operating in production worldwide. We design and operate semi- and fully automated welders for precision and dependable quality.

Friction Welding Machines for Consumer Products

Machine-welded parts and products mean fewer errors and more savings. They boast cleaner aesthetics and improved strength, joining metals incompatible with traditional welding.

There is a reason why MTI-built friction welders are still operating in production worldwide. We design and operate semi- and fully automated welders for precision and dependable quality.

ROTARY FRICTION WELDING

Improve your production time with MTI’s Rotary friction welder machines’ fast weld cycles. Our advanced controls ensure error-free precision.

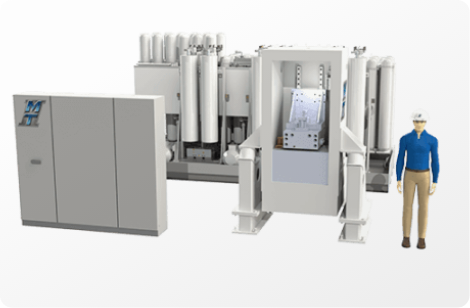

LOW FORCE FRICTION WELDING

Do you have components that cannot handle high welding loads? Low Force friction welding allows the solid-state welding of components that shouldn’t be used with high force.

LINEAR FRICTION WELDING

If your components involve complex geometries, MTI Linear friction machines produce a 100% butt joint weld through the contact area.

FRICTION STIR WELDING

Enhance your designs with Friction Stir welding. MTI’s Friction Stir welders ensure minimal distortion with low heat and small heat-affected zones, delivering superior aesthetics and structural integrity.

Explore Our Sample Parts

Curious if your desired shapes and materials are feasible? Look no further. From consumer electronics, to barbells, to golf putters, our sample parts will provide the answers you need.

Contract Manufacturing Services

Have a project in mind? We’ve got you covered. From consultation to testing, manufacturing, maintenance, and personnel training, MTI offers the expertise and resources to complete your project seamlessly, all in one place.

Contract Manufacturing Services

Have a project in mind? We’ve got you covered. From consultation to testing, manufacturing, maintenance, and personnel training, MTI offers the expertise and resources to complete your project seamlessly, all in one place.

Consumer Products Friction Welding Machines for R&D

Need to test your new project but lack the necessary tools?

Utilize our in-house R&D machines to put your materials and applications to the test. Our advanced friction welding machines are here to help you innovate.

MTI’s newest Low Force friction welding machine, the Microwelder, uniquely suited to join the smallest of parts.

Learning Center

Case Studies

Videos

Consumer Products Video

Consumer Products Video

Get the information you need, before you need it — free and straight to your inbox from industry experts.