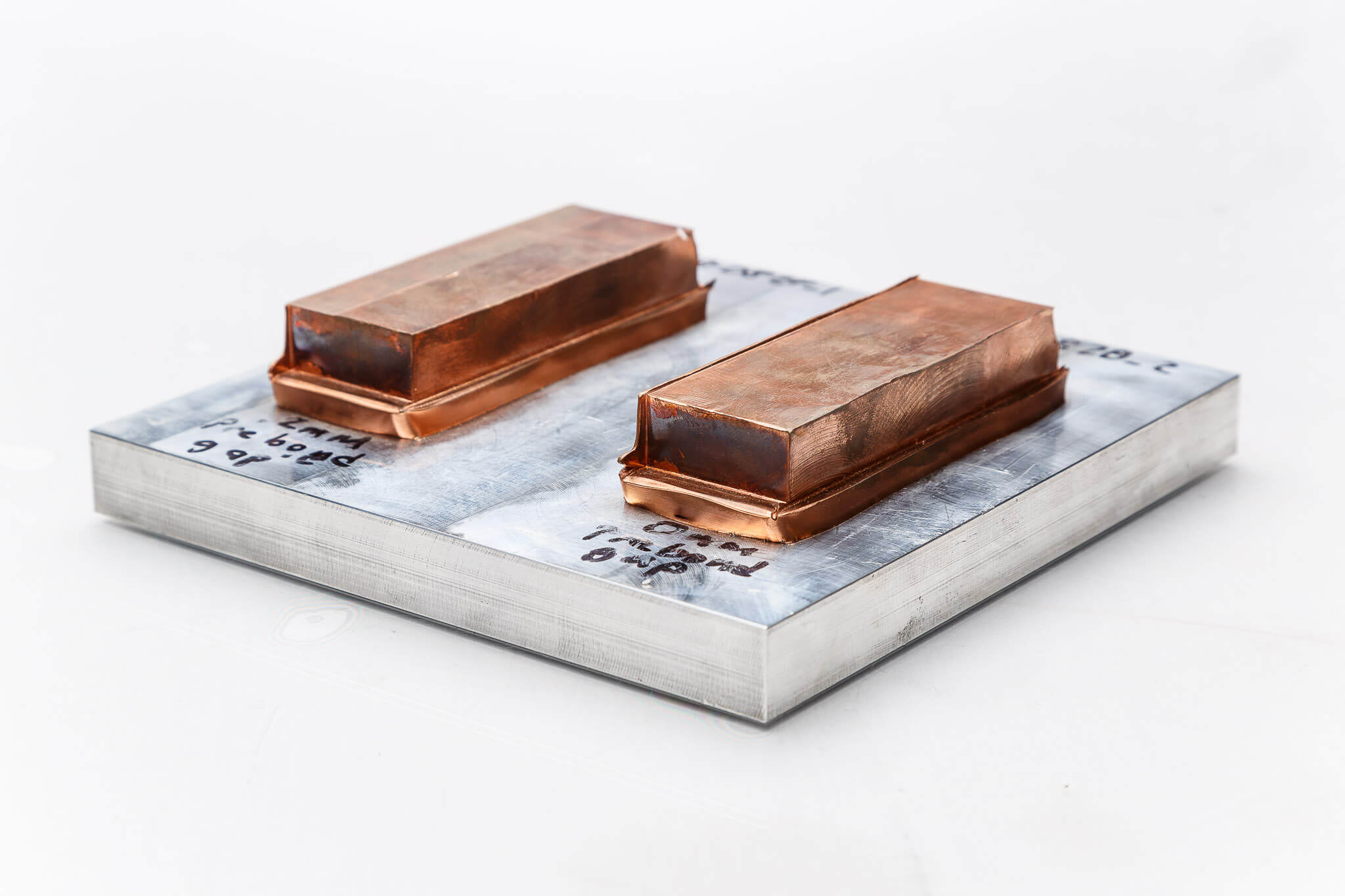

Bi-metallic application linear friction welding of copper alloy block to aluminum plate

All our parts have a story behind them. Explore sample parts below to uncover applications, materials, technology and geometrical fittings that might be right for your next project.

Bi-metallic application linear friction welding of copper alloy block to aluminum plate

Bi-metallic application linear friction welding of copper bars to aluminum plate top angle view

Linear friction welding of all shapes of parts

Larger custom aluminum sheet sizes created by friction stir welding from smaller stock pieces

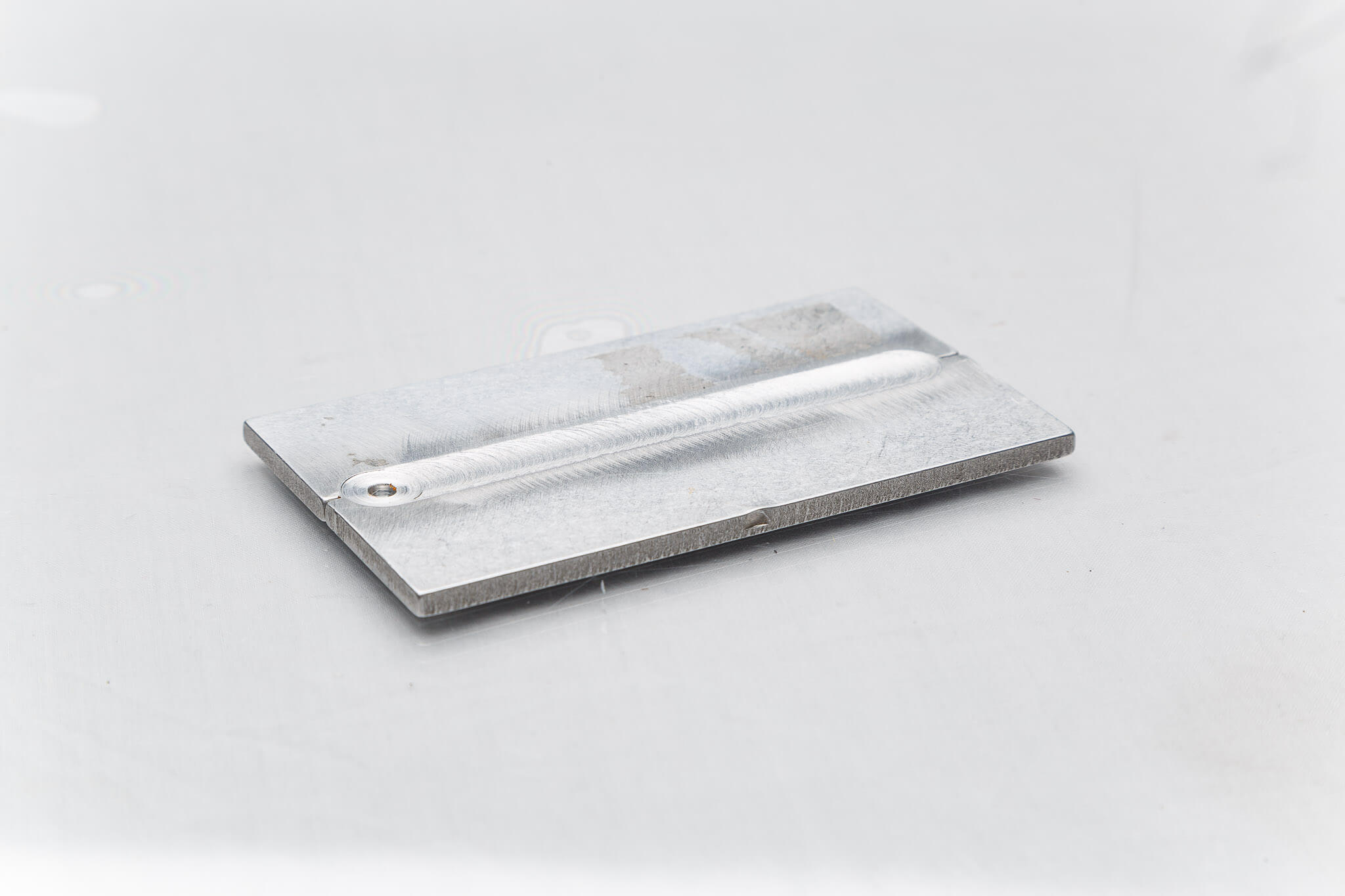

Top view - friction stir welded MTI business card .100" thick aluminum plate

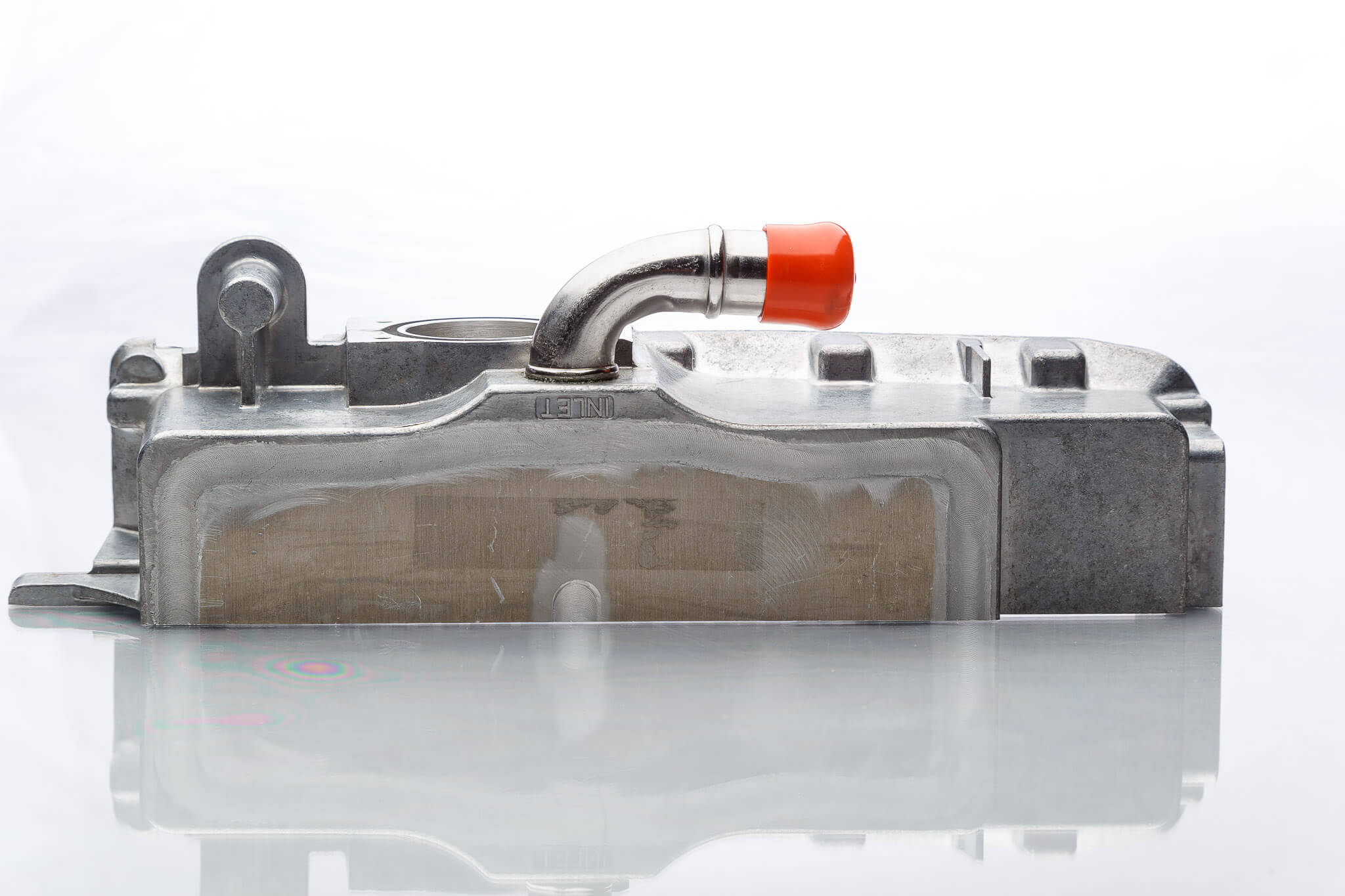

Section view of hybrid vehicle aluminum plate welded to cast aluminum heat exchanger box for a water tite seal. FSW weld path on plate is facing up.

4' section view of joining of multiple aluminum extrusion panel sections up to 50' long via dual weld head (upper & lower) welds

Tailor welded blanks top view -1mm and 2mm thick aluminum sheets jointed prior to stamping. Used for vehicle lightweighting. Heavier 2mm material is deployed in crtical form support areas

Multiple pieces of High Strength Steel Alloy joined in a single friction stir pass for low heat input sheet joining (reducing distortion)

Drive shaft sectioned part front view - tool exit hole shown -lightweighting vehicle while maintaining or increasing durability

Welded machine tool spindle blank. Replaces costly forging.

Welded machine tool spindle blank - as machined

Welded machine tool spindle blank. Replaces costly forging.

Welded machine tool spindle blank - as machined

Keyway and T-slot cutters. Welded blanks made from AISI6145 shanks and M4 tool steel heads.

Countersinks. High-speed steel heads welded to mild-steel shanks.

Twist drill blank. Welded M10 tool steel bodies to SAE4140 shanks.

Tool steel to carbon steel drill bit

Air conditioner rotor assembly. Outer rotor pole is welded to inner rotor pole then this assembly is welded to pulley blank.

Bumper shocks. Tubing welded to stamping for impact absorbing bumper mounts.

Shock absorber base cup. Weld between threaded stud and base cup firmly traps washer in place.

Input shaft for automotive transmission. Stamped hub to machined barstock.

Figure 2 of 2 Welded stabilizer bar cross-section

Figure 1 of 2 Stabilizer bars. Tube welded to solid end.

Sport utility 4x4 interconnecting shaft

Front suspension struts

Drive extension (internal spline one end).

Brake caliper. Tubing joined to formed caliper.

Transmission input shaft

Air conditioner accumulator. Aluminum housing.

Wheel spindle

Transmission gear. Finished spiral bevel gear welded to tubular shaft.

Turbocharger

Front wheel drive shaft

Drive shaft

Worm gear drive shaft

Clevis

Materials:

Technology:

Geometry: Bar to Bar

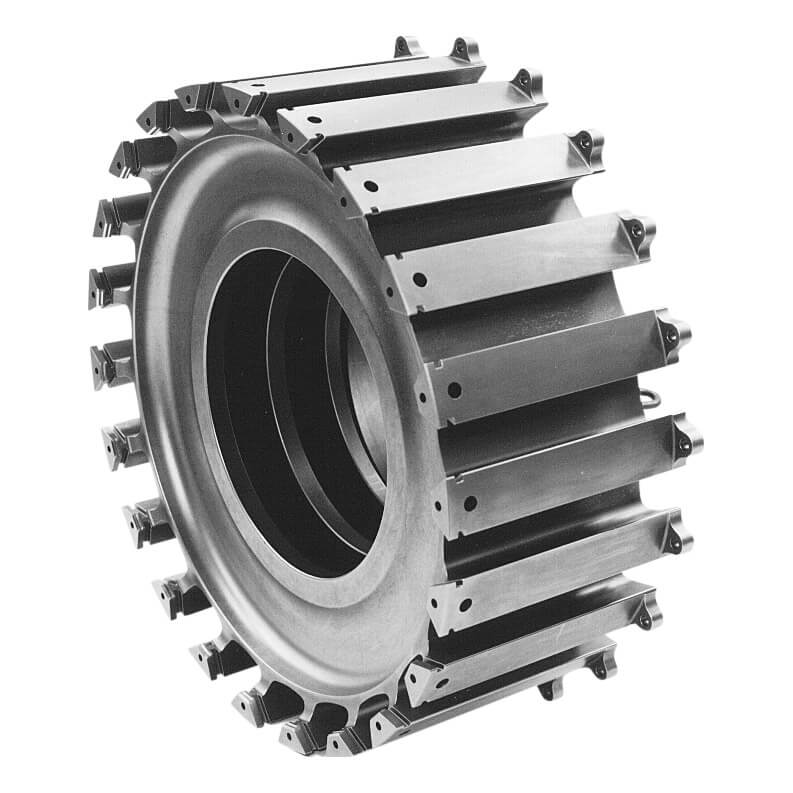

Torque converter pump

Torque converter cover. Three mounting nuts welded to cover for mounting of flywheel ring gear.

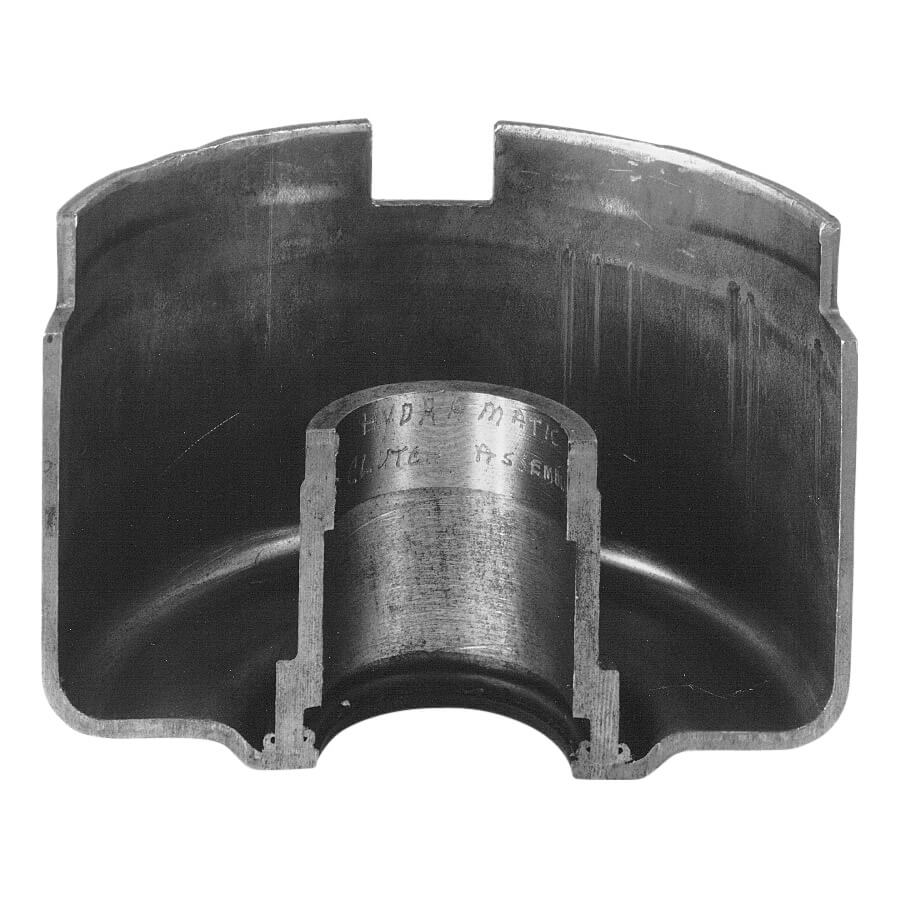

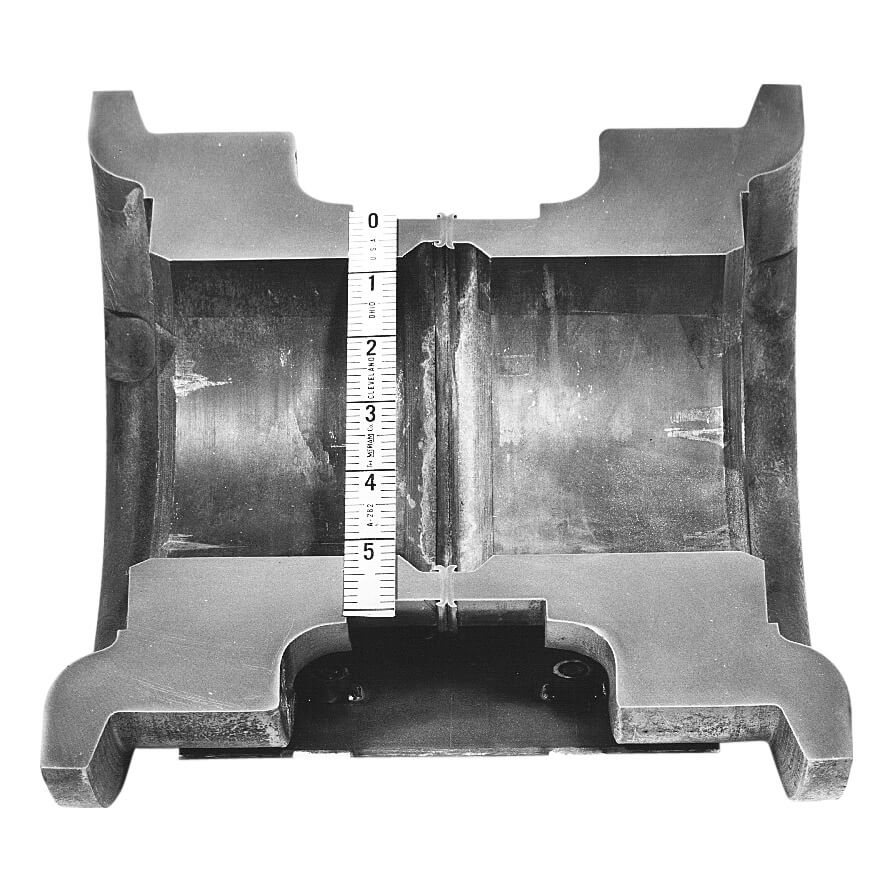

Figure 2 of 2 Direct clutch drum and hub assembly cross-section.

Figure 1 of 2 Direct clutch drum and hub assembly used in automatic transmissions. Mild steel tubing welded to cold-formed clutch drum. Cross-section.

Electric motor housing and shaft for automotive cooling fan.

Automotive transmission component. Machined tubing welded to cold-formed end.

Rear axle housing tube. Forged tube end welded to tube stock.

Automotive axle tube

Water pump hub and shaft

Steering shaft welded to pre-assembled knuckle

Universal joint assembly with welded extension shaft

Countersinks. High-speed steel heads welded to mild-steel shanks.

Constant Velocity Joint

Cross-section of hydraulic jack showing two tubularwelds which were made simultaneously to the base plate

Automotive hydraulic jack. Fabricated from tubing and plate stock.

Starter pinion assembly. Sintered steel gear welded to sleeve.

Viscous drive fan shaft couplings replace forgings.

Alternator bracket. Barstock welded to plate, replaced forging.

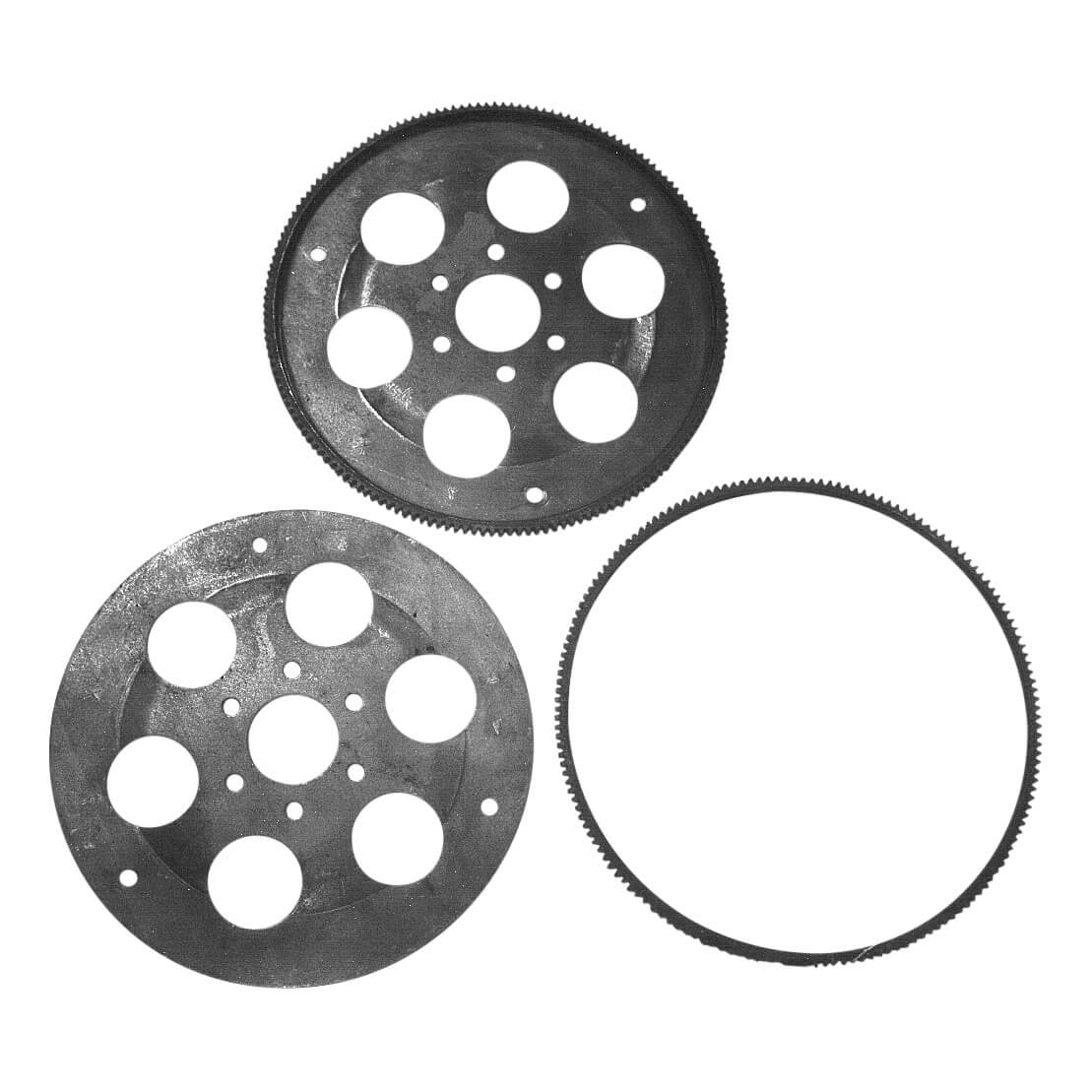

Rolled ring gear welded to flywheel stamping produces distortion-free flywheel ring gearauto

Fan shaft bracket assembly. Barstock welded to plate replaces machined forging.

Automatic transmission output shaft. Stamped steel flange welded to barstock.

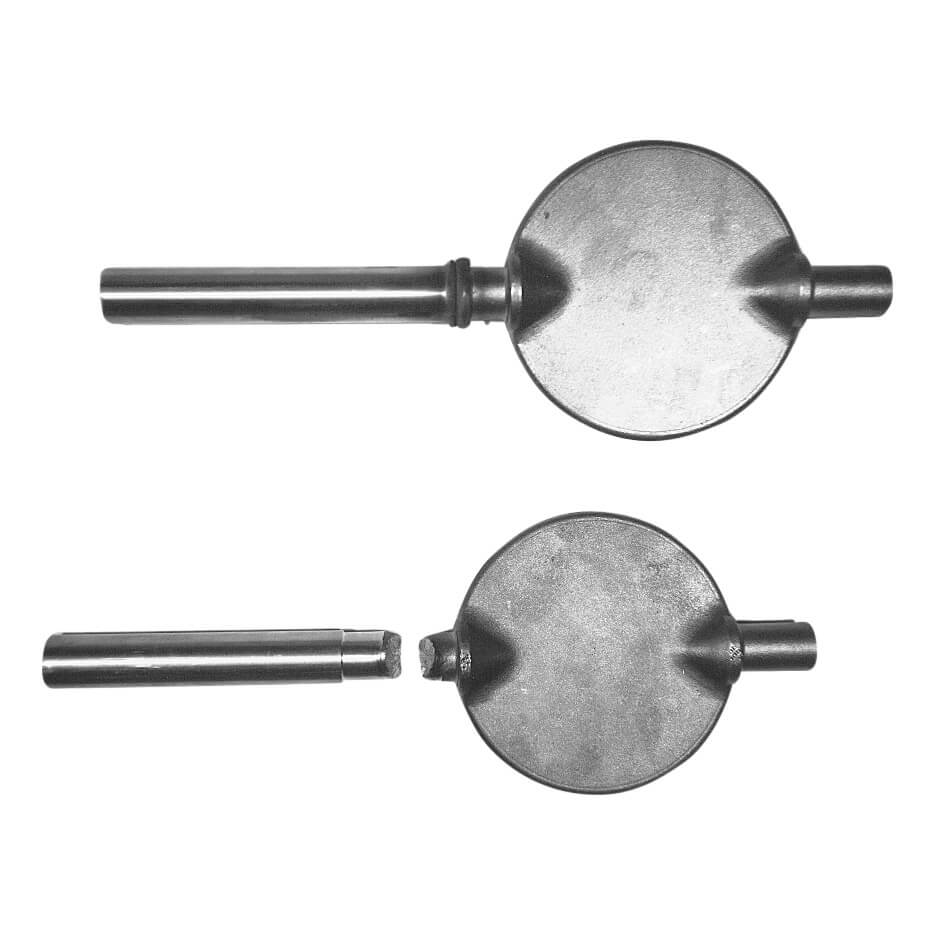

Bi-metallic engine exhaust valves showing head and stem components, as-welded valve and welded valve with flash removed by shearing.

Experimental hollow automotive rear axle. Tubing welded to hub forging and spline blank. Replaces solid forging for weight reduction.

Flanged Axle

Hollow engine valves for lightweight and liquid-cooled applications

Transmission part

Retainer-differential bearing blank cross-section (left). Bearing housing retainer for transaxle (right).

Experimental chassis component

Experimental aluminum suspension link

Figure 2 of 2 Wheel rim cross-section

Figure 1 of 2 Wheel rim

Figure 2 of 2 Passenger side airbag inflator and cross-section

Figure 1 of 2 Passenger side airbag inflator and cross-section

Side-impact airbag inflators

Driver and passenger side airbag inflators

Hybrid passenger side airbag inflator

Passenger side airbag

Driver side airbag inflator - cross-section

Figure 2 of 2 - Transition joint for cryogenic application

Figure 1 of 2 - Transition joint for cryogenic application

Solid aluminum bar to stainless steel tube

Pin heading done using interrupted weld cycle

Copier fuser roller

Electrical connector

Tensile specimen

Bi-metallic pump motor shaft. SS stub joined to CS shaft for corrosion resistance.

Marine outboard engine drive shaft

Bar stock welded to clevis forging for manufacture of large (5 inches (127 mm) diameter and larger) piston rods

Hydraulic piston rod

Track adjusting yoke for commercial tracked vehicles

Hydraulic piston rods. Rod eyes cut from heavy-wall tubing welded to pre-chromed bar stock.

Torque rod. Forged eye welded to various barstock lengths.

Truck rear suspension link welded on twin 150 Inertia Welder. Ends are oriented to within ±1° of each other.

Lift link-ball socket. Forged couplings welded to tubing and barstock.

Lift screw. Roll threaded stock cut to length and welded to screw machined ends.

Chain drive sprocket

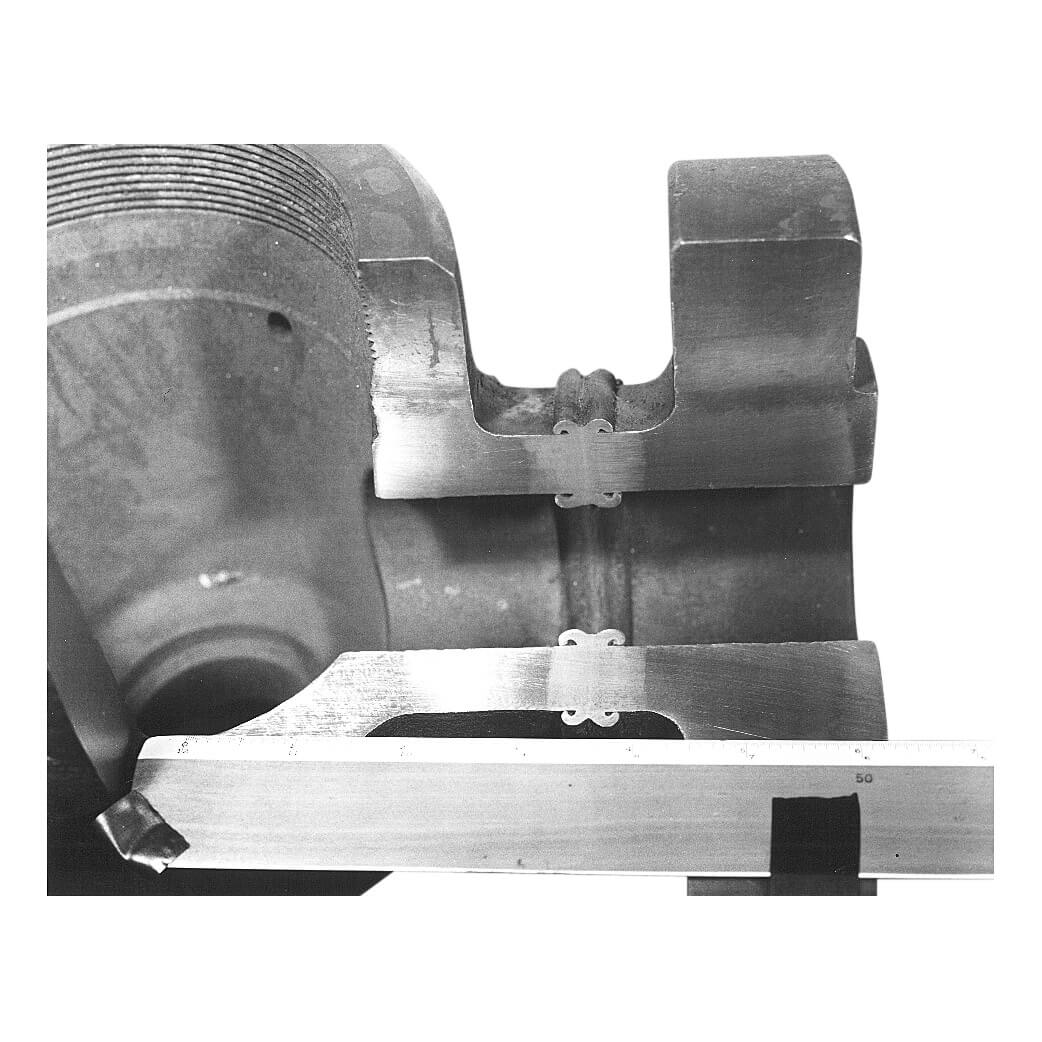

Two pre-finished transmission gears welded using precision piloted tooling

Cluster gear. Small finished gear welded to larger gear blank.

Oil pump gears. Welded bar stock replaces forged blanks. 15% - 30% cost reduction (depending on size and usage).

Finished gear welded to clutch drum

Pin assembly. Pre-chromed pin welded to retaining plate

Front axle yoke shaft for four-wheel-drive vehicles - bar stock to yoke forging

Universal joint clevis

Power control drive shaft for motor grader. Inertia weldment replaces upset forging (left) which required five straightening operations

Forged wheel spindles joined to 5 inches (127 mm) diameter - 5 inches (12.7 mm) wall tubing to produce trailer axles.

Truck trailer brake S-cam

Rear axles for tractors - 4 inches (101.6 mm) diameter bar stock welded to hub forging

Steel-backed, bronze-laminate thrust washers and sleeves welded together to produce track roller bushings. Replaced costly, solid bronze castings.

Track roller. Forged halves welded together to produce track roller assemblies.

Diesel engine piston

Water pump - finished

Water pump - as welded

Diesel engine pre-combustion chamfer cross-section

Aerospace heat pipe

Lightweight piston for aircraft pump

Aircraft hook bolts

Stator vane adjustor lever

Bi-metallic aircraft rivets

Ball screw actuator

Left: Stator vane root weld - as machined, Center: Stator vane root weld - with flash removed, Right: Stator vane root weld - as welded.

Military jet engine fan shaft, cross-section - as machined

Commercial jet engine fan shaft - as welded

Fan shaft for military jet engine

Forged clevis to tubing for manufacture of ball screw. Actuates swing wing on F-14 fighter aircraft.

Military jet engine compensating shaft - as welded

Bosses welded to accumulator housing

Extension welded to four-blade propeller hub forging

Jet engine component - as machined

Landing gear component

Landing gear drag brace

Jet engine compressor rotor - as welded

Fan blade rotor

Cluster gear cross section

Cluster gear

Tube to rotor assembly

Low compression titanium rotor assembly

Water pump gear

Figure 2 of 2 - Copper alloy rotating band radially welded to 155 mm alloy steel projectile body and cross-section

Figure 1 of 2 - Copper alloy rotating band cross-section

Impact wrench extensions

Adjusting link for tracked vehicle

Copper alloy band to 30 mm steel body

Mortar round

Mid-case bomb assembly - 18 inches (457 mm) outside diameter, 43 in2 (27 740 mm2) weld area

Front bomb case assembly - 18 inches (457 mm) outside diameter

Drive shaft torque tubes for amphibious personnel carrier

Experimental windscreens to projectiles

Closure for smoke mortar fill hole

Experimental machine gun barrel liner

Figure 2 of 2 - Fuze liners. Drawn thin-wall tubing to heavy-wall tubing rings.

Figure 1 of 2 - Fuze liners. Drawn thin-wall tubing to heavy-wall tubing rings.

Fuze liner

Figure 2 of 2 - Formed cap welded to tubing for manufacture of bomblet

Experimental aluminum smoke mortar

Figure 1 of 2 - Formed cap welded to tubing for manufacture of bomblet

Oil well head manifold tubing cross-section

Oil well drill pipe. Close-up of tooljoint to drill pipe weld - male end.

Oil well drill pipe. Close-up of tooljoint to drill pipe weld - female end.

Sucker rod. Threaded end connector welded to forged sucker rod.

Geological core drill - end blank welded to tubing

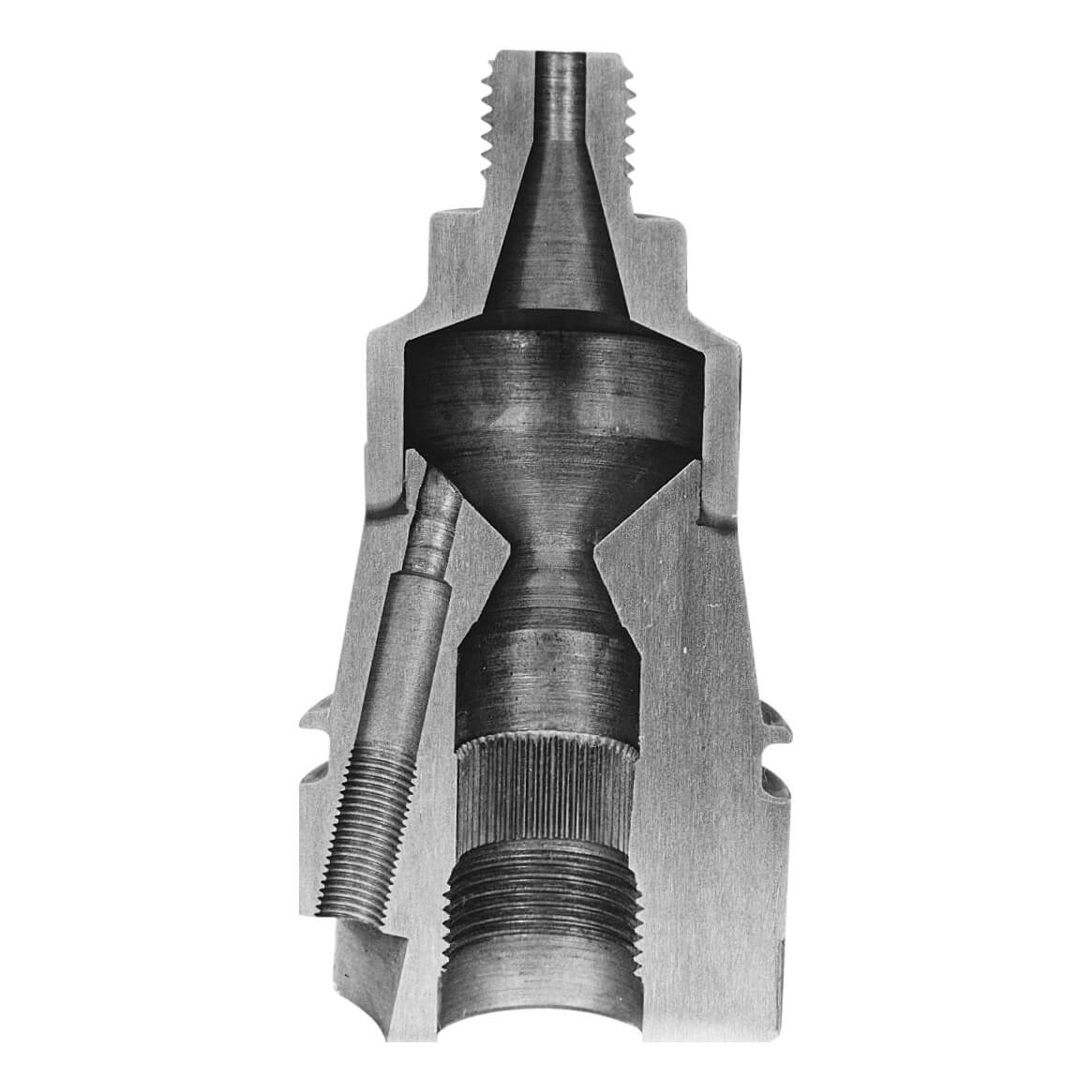

High-pressure valve body weld cross-section

Butterfly valves. Wrought stainless steel extension welded to investment cast stainless steel butterfly valver: Stator vane root weld - with flash removed, Right: Stator vane root weld - as welded.

High-pressure valve body. Forged flanges welded to forged valve body.

MTI UK

MTI UK  FWT

FWT