Bumper shocks. Tubing welded to stamping for impact absorbing bumper mounts.

All our parts have a story behind them. Explore sample parts below to uncover applications, materials, technology and geometrical fittings that might be right for your next project.

Bumper shocks. Tubing welded to stamping for impact absorbing bumper mounts.

Air conditioner accumulator. Aluminum housing.

Wheel spindle

Torque converter cover. Three mounting nuts welded to cover for mounting of flywheel ring gear.

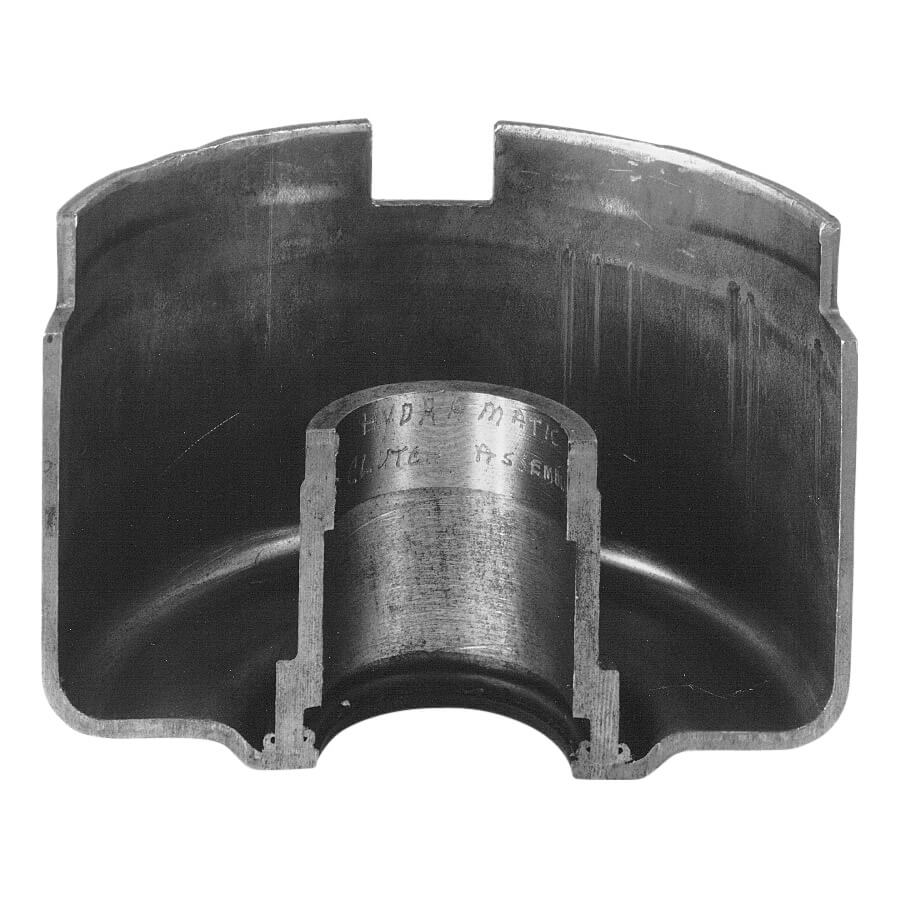

Figure 2 of 2 Direct clutch drum and hub assembly cross-section.

Automotive transmission component. Machined tubing welded to cold-formed end.

Cross-section of hydraulic jack showing two tubularwelds which were made simultaneously to the base plate

Automotive hydraulic jack. Fabricated from tubing and plate stock.

Starter pinion assembly. Sintered steel gear welded to sleeve.

Viscous drive fan shaft couplings replace forgings.

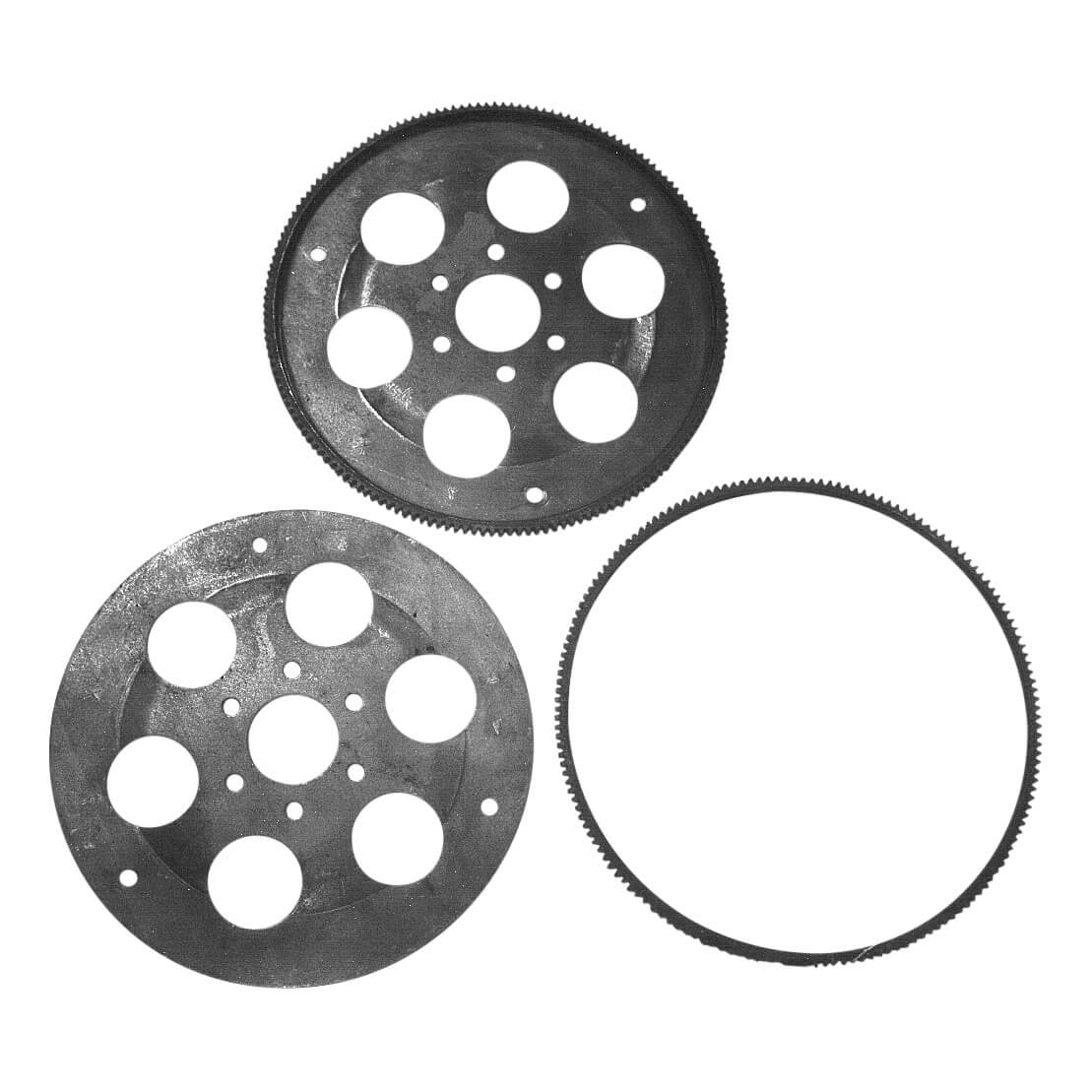

Rolled ring gear welded to flywheel stamping produces distortion-free flywheel ring gearauto

MTI UK

MTI UK  FWT

FWT