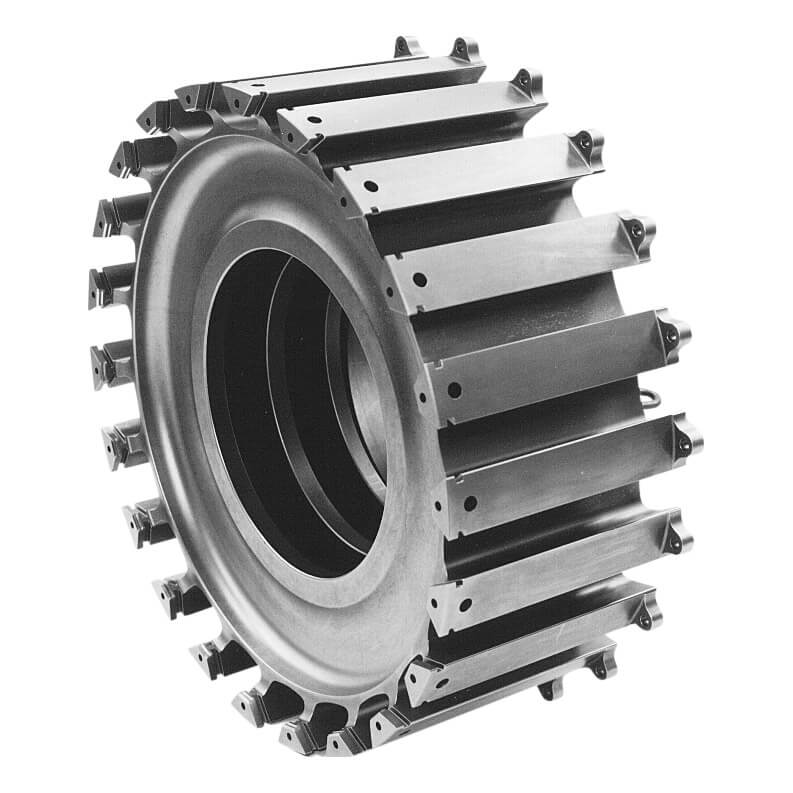

Air conditioner rotor assembly. Outer rotor pole is welded to inner rotor pole then this assembly is welded to pulley blank.

All our parts have a story behind them. Explore sample parts below to uncover applications, materials, technology and geometrical fittings that might be right for your next project.

Air conditioner rotor assembly. Outer rotor pole is welded to inner rotor pole then this assembly is welded to pulley blank.

Brake caliper. Tubing joined to formed caliper.

Turbocharger

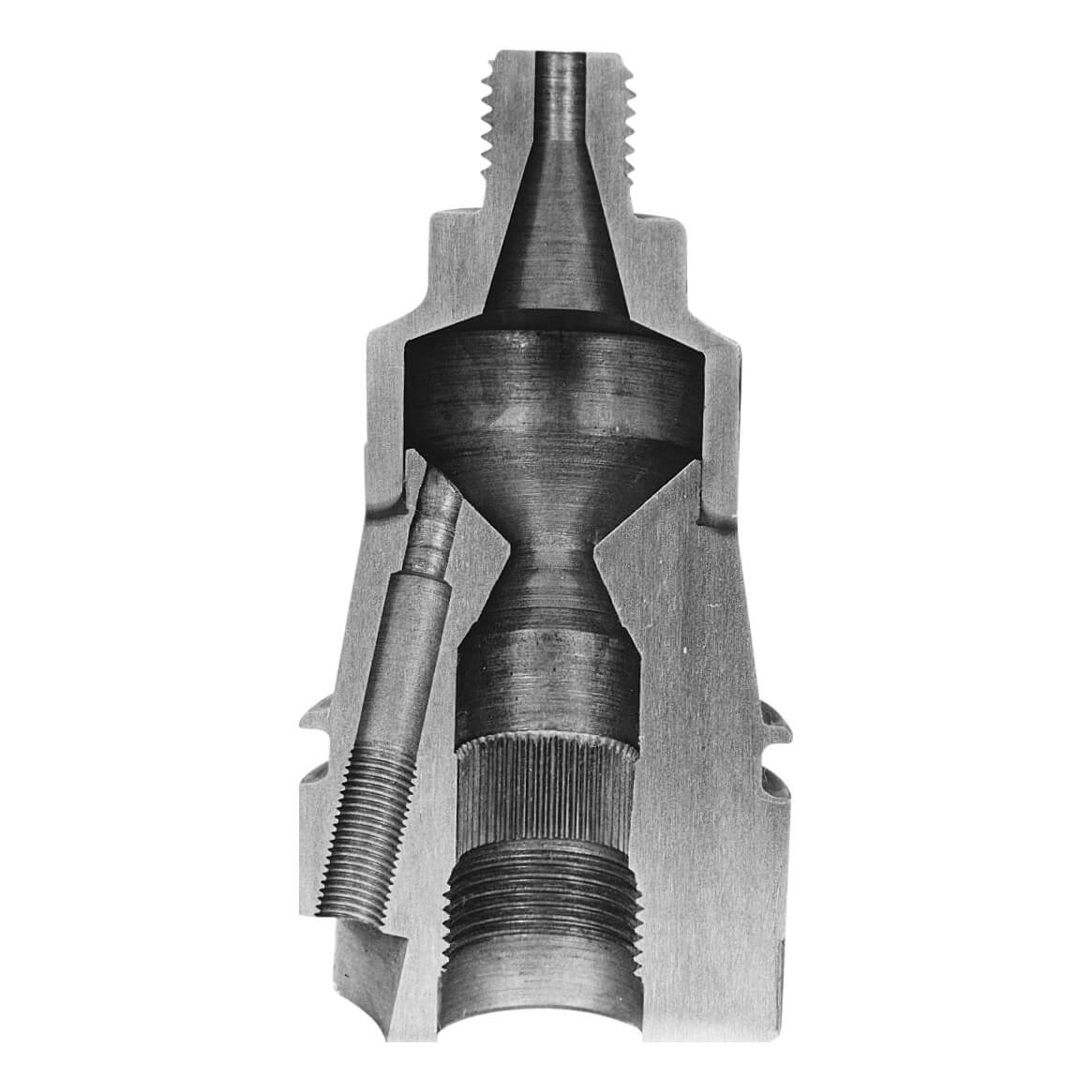

Figure 1 of 2 Direct clutch drum and hub assembly used in automatic transmissions. Mild steel tubing welded to cold-formed clutch drum. Cross-section.

Electric motor housing and shaft for automotive cooling fan.

Solid aluminum bar to stainless steel tube

Pin heading done using interrupted weld cycle

Copier fuser roller

Cluster gear. Small finished gear welded to larger gear blank.

Diesel engine pre-combustion chamfer cross-section

Fan blade rotor

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

Keeping this cookie enabled helps us to improve our website.

Please enable Strictly Necessary Cookies first so that we can save your preferences!

More information about our Cookie Policy

MTI UK

MTI UK  FWT

FWT