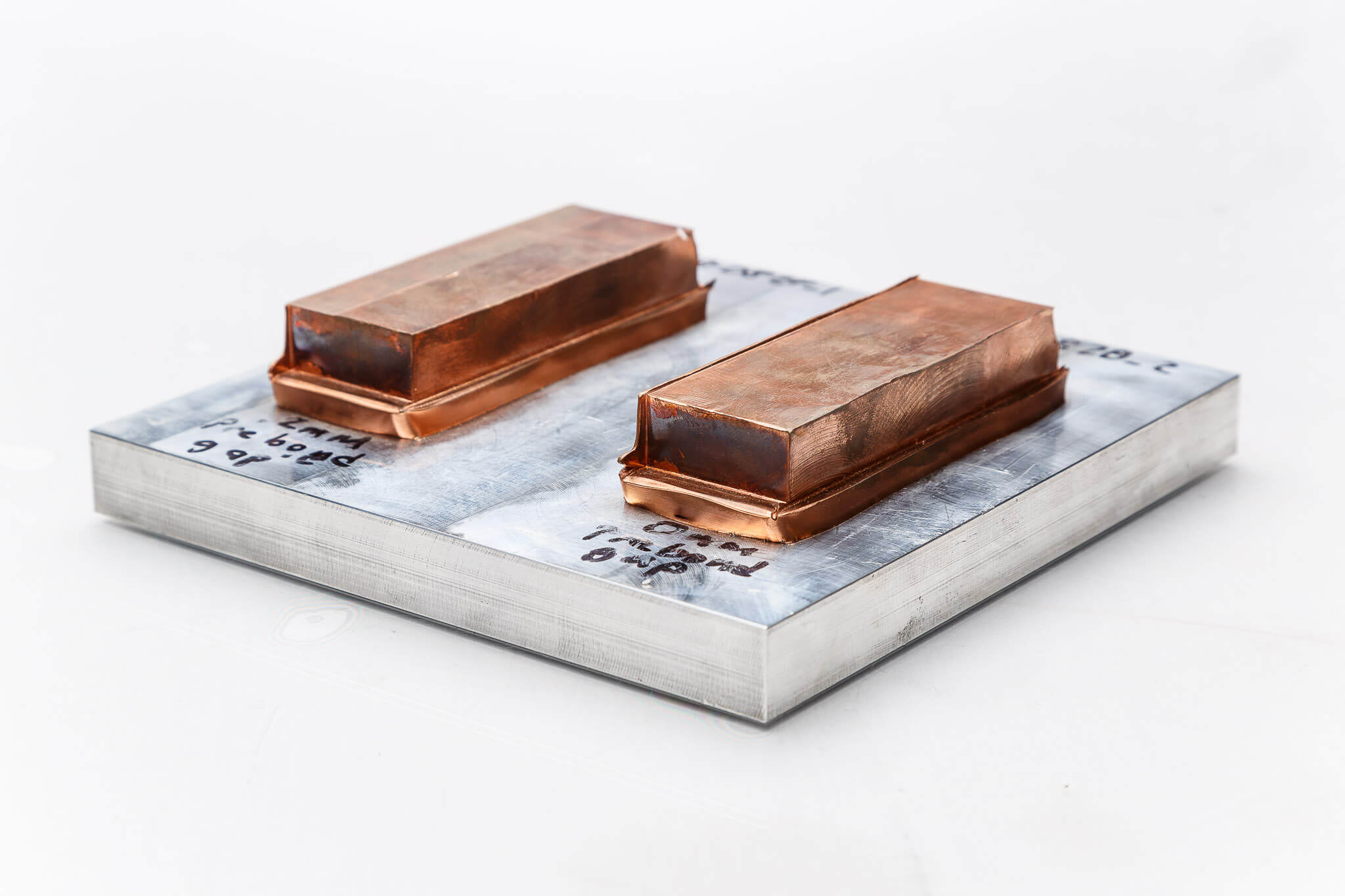

Bi-metallic application linear friction welding of copper alloy block to aluminum plate

All our parts have a story behind them. Explore sample parts below to uncover applications, materials, technology and geometrical fittings that might be right for your next project.

Bi-metallic application linear friction welding of copper alloy block to aluminum plate

Bi-metallic application linear friction welding of copper bars to aluminum plate top angle view

Linear friction welding of all shapes of parts

Welded machine tool spindle blank - as machined

Welded machine tool spindle blank. Replaces costly forging.

Welded machine tool spindle blank - as machined

Keyway and T-slot cutters. Welded blanks made from AISI6145 shanks and M4 tool steel heads.

Countersinks. High-speed steel heads welded to mild-steel shanks.

Shock absorber base cup. Weld between threaded stud and base cup firmly traps washer in place.

Input shaft for automotive transmission. Stamped hub to machined barstock.

Transmission input shaft

MTI UK

MTI UK  FWT

FWT