From Friction Welding Machines to Parts, We Make It Happen

❭ Contract

Welding

❭ Contract

Welding

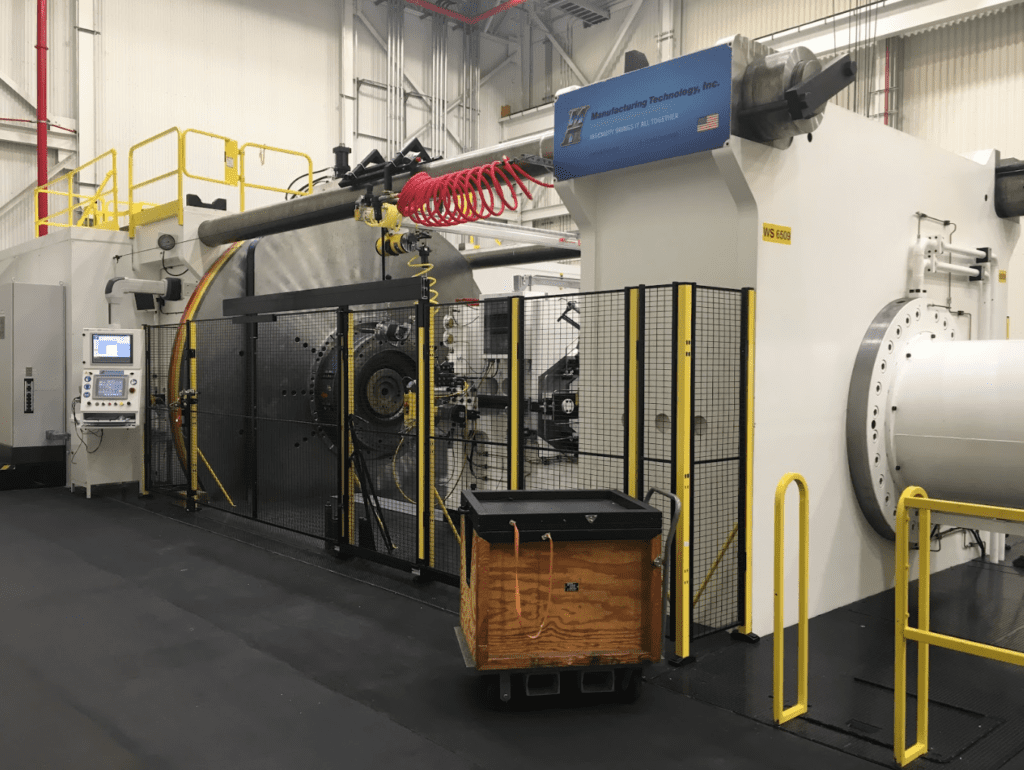

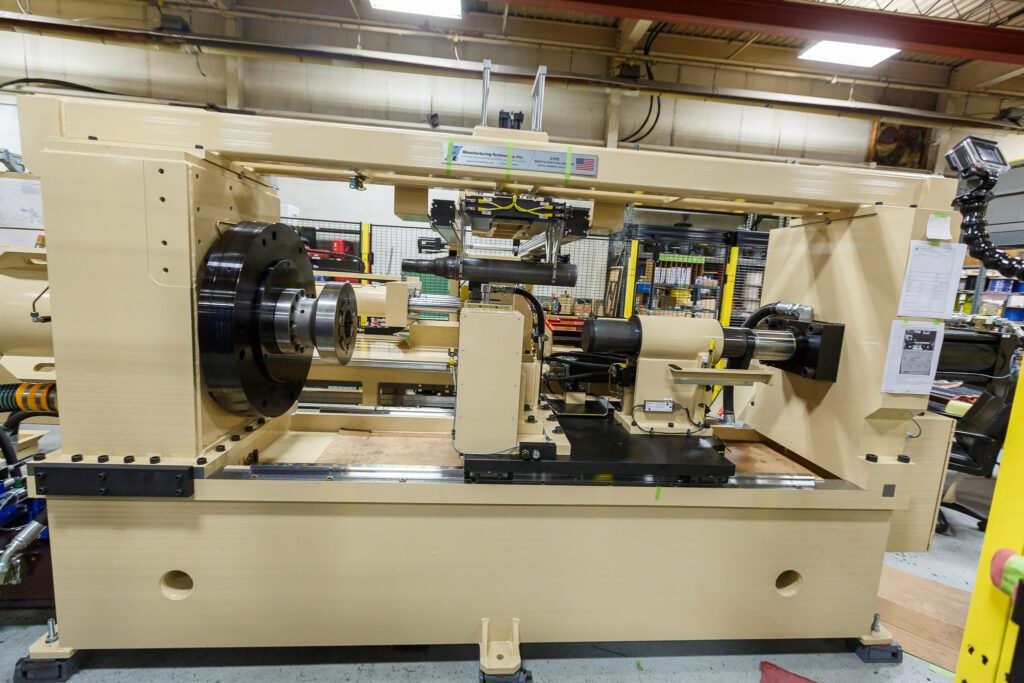

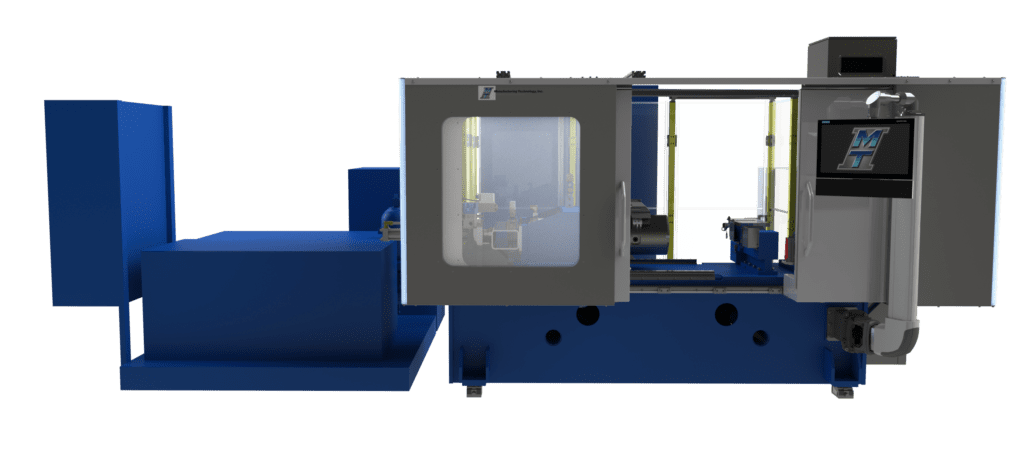

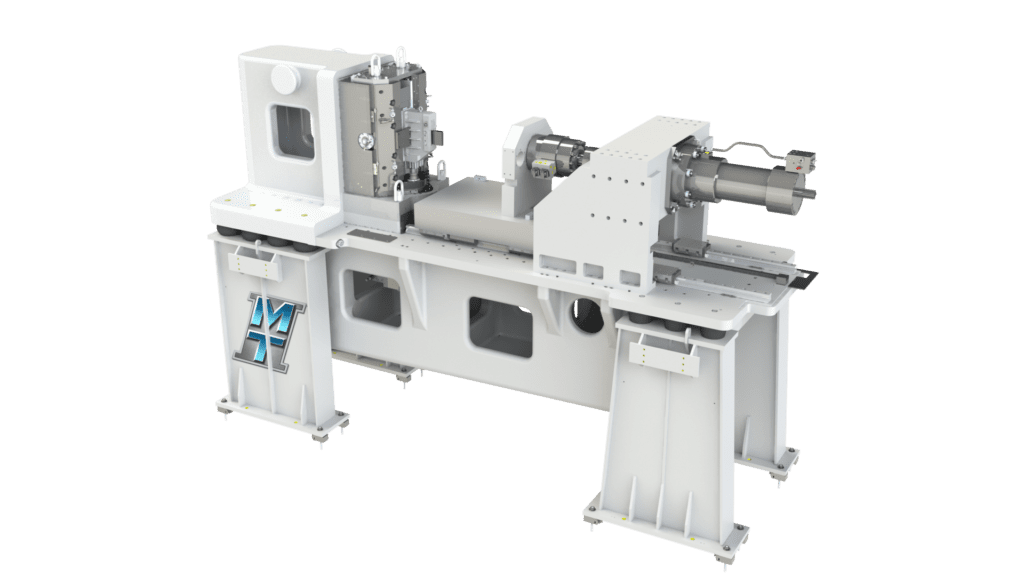

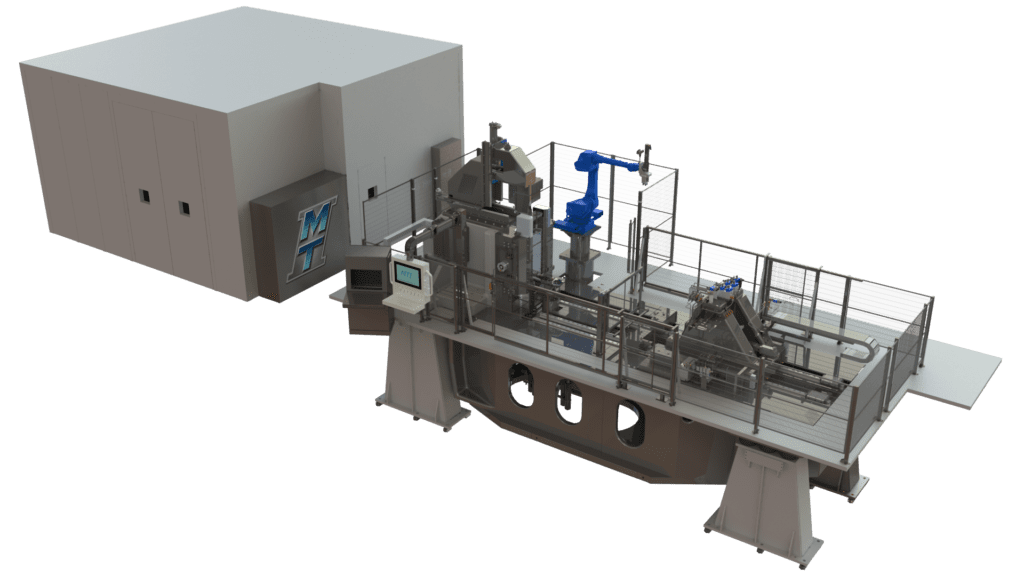

❭ Friction Welding

Machines

❭ Friction Welding

Machines

❭ Global Service

& Parts

❭ Global Service

& Parts

World Leader in Friction

Welding Technology

World Leader in Friction

Welding Technology

Is friction welding right for your project?

Friction Welding is a diverse and adaptive process that can be used for many applications across several industries. As a solid-state joining process, Friction Welding offers a range of benefits and advantages as opposed to other welding techniques. It’s a proven and trusted process for many Tier 1 suppliers and OEMs. If you’re unsure of where to start, let us take it from here.

Five friction welding technologies that will change everything.

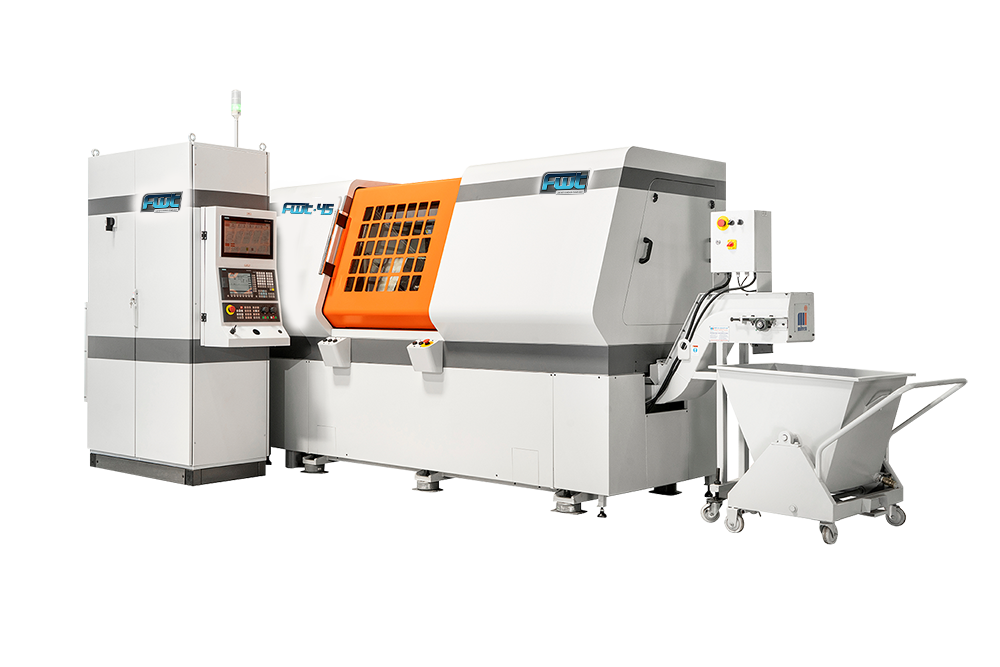

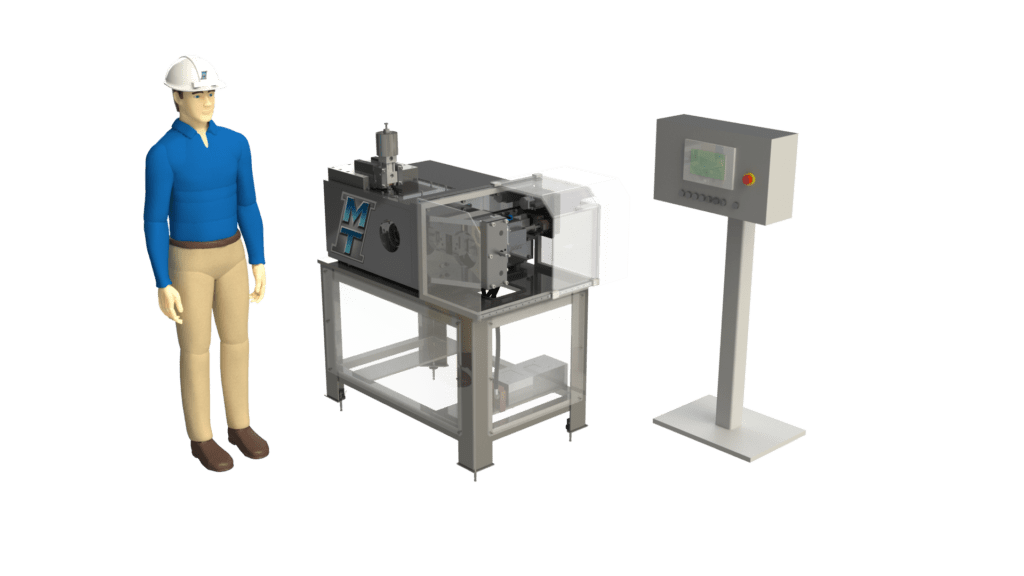

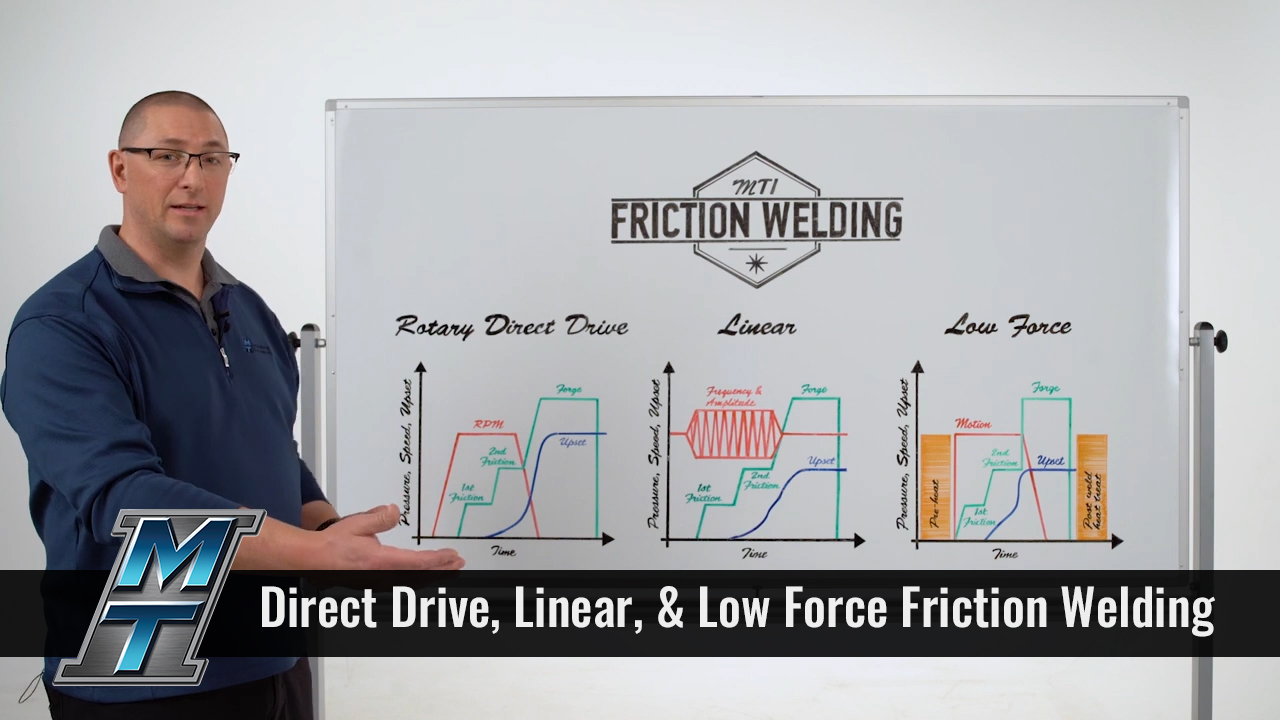

Low Force Friction Welding

Increase Precision at a

Fraction of the Force

An optimized form of traditional friction welding, Low Force

Friction Welding touts smaller and smoother flash, faster

cycle times, and reduced machine size.

Low Force Friction Welding

Increase Precision at a Fraction of the Force

An optimized form of traditional friction welding, Low Force Friction Welding touts smaller and smoother flash, faster cycle times, and reduced machine size.

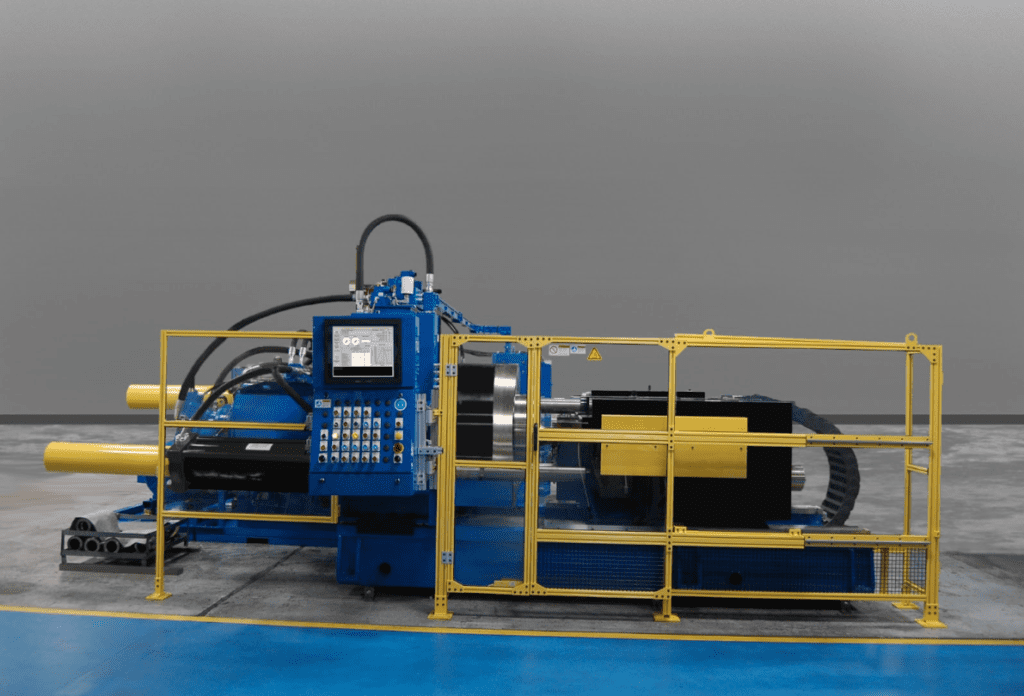

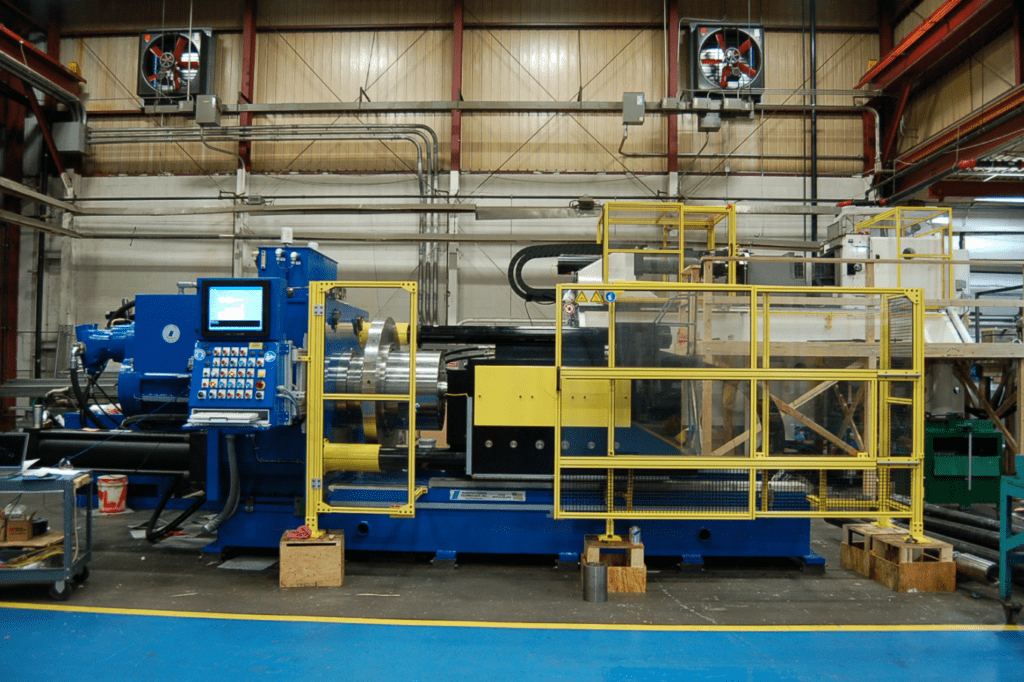

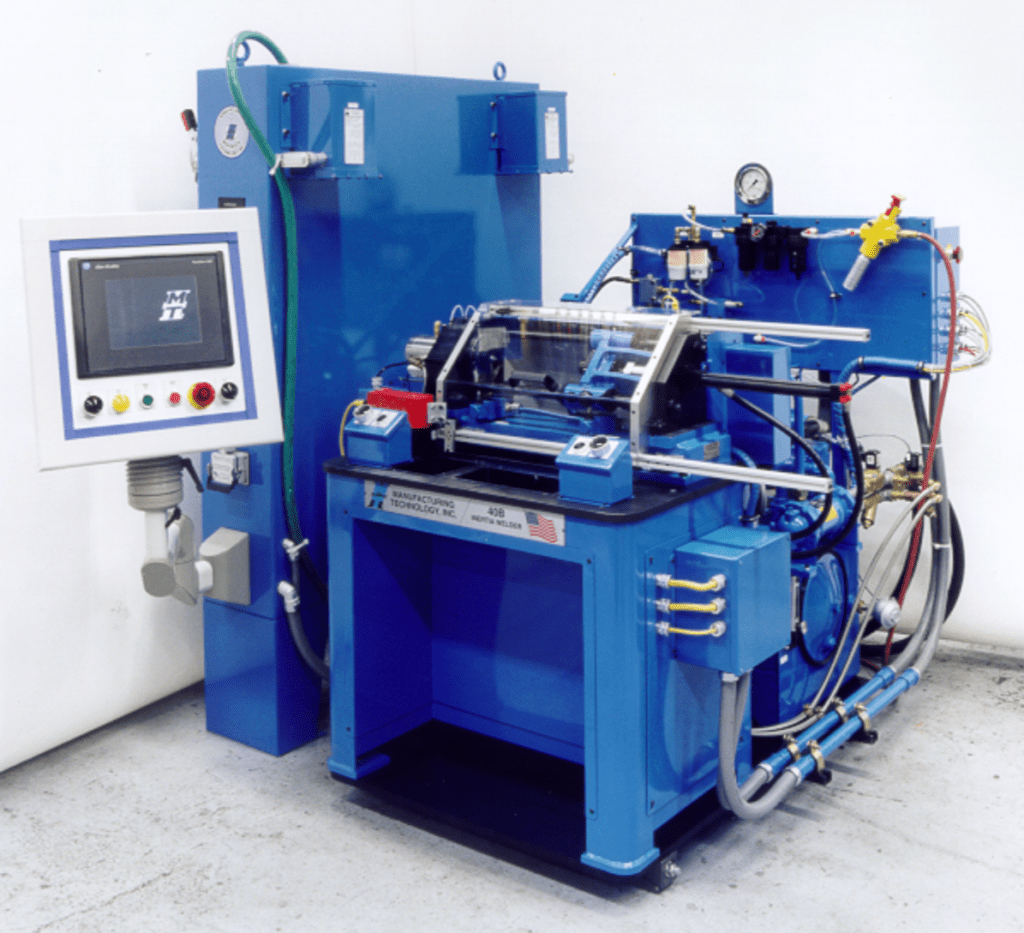

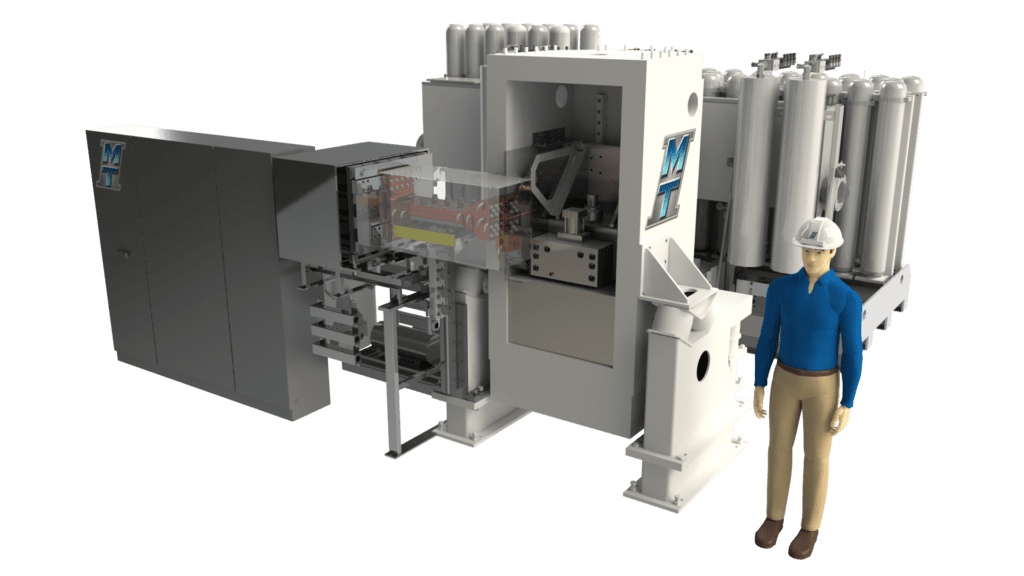

Inertia Friction Welding

Scaling Up

Inertia is a subset of the Rotary Friction Welding process and allows for the scalability of applications.

Inertia Friction Welding

Scaling Up

Inertia is a subset of the Rotary Friction Welding process and allows for the scalability of applications.

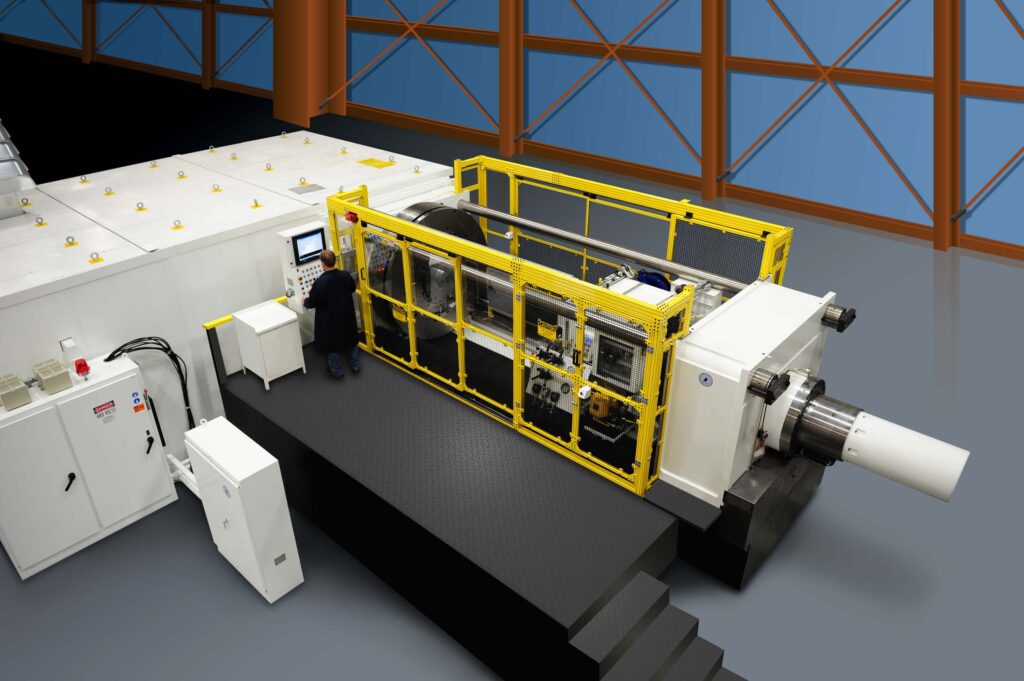

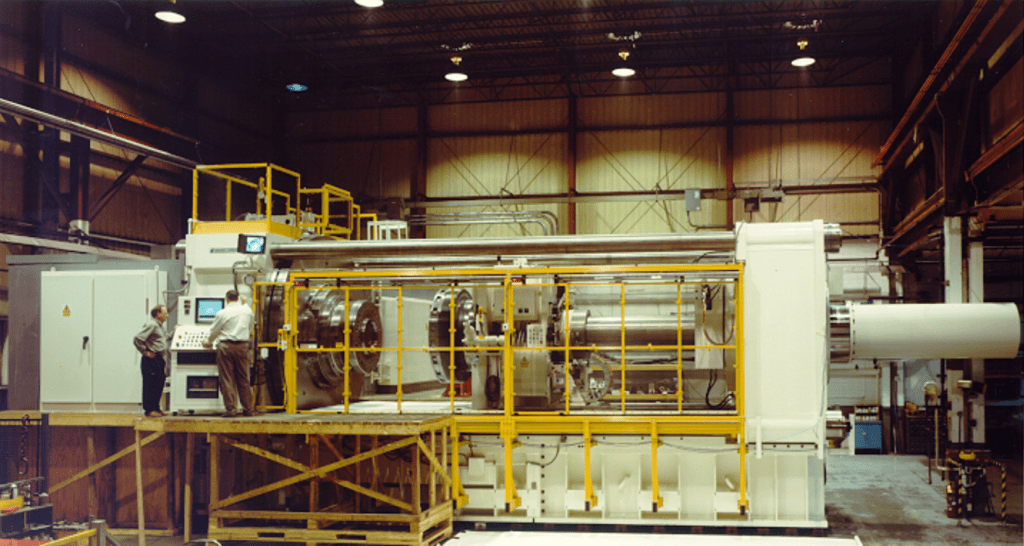

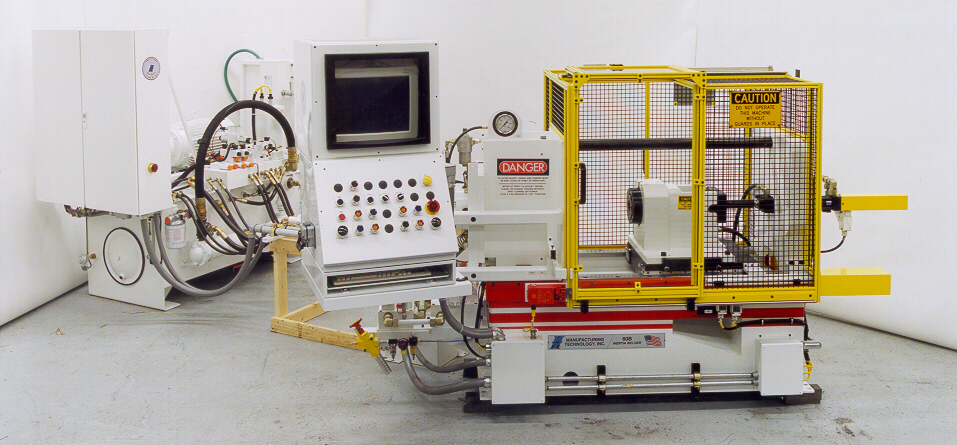

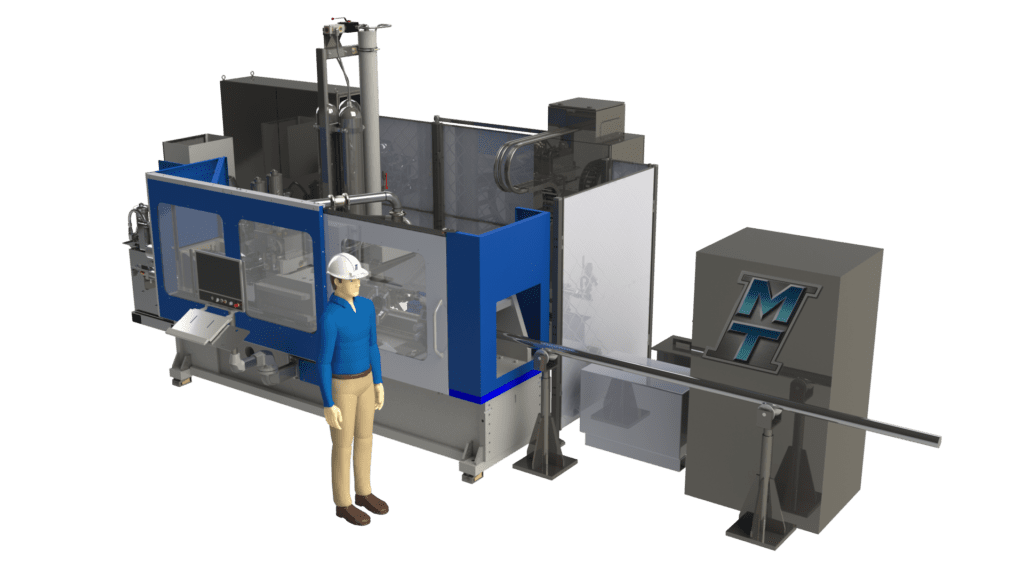

Direct Drive Friction Welding

The Legacy Process

Direct Drive is a subset of the Rotary Friction Welding process and is the original friction welding technology.

Direct Drive Friction Welding

The Legacy Process

Direct Drive is a subset of the Rotary Friction Welding process and is the original friction welding technology.

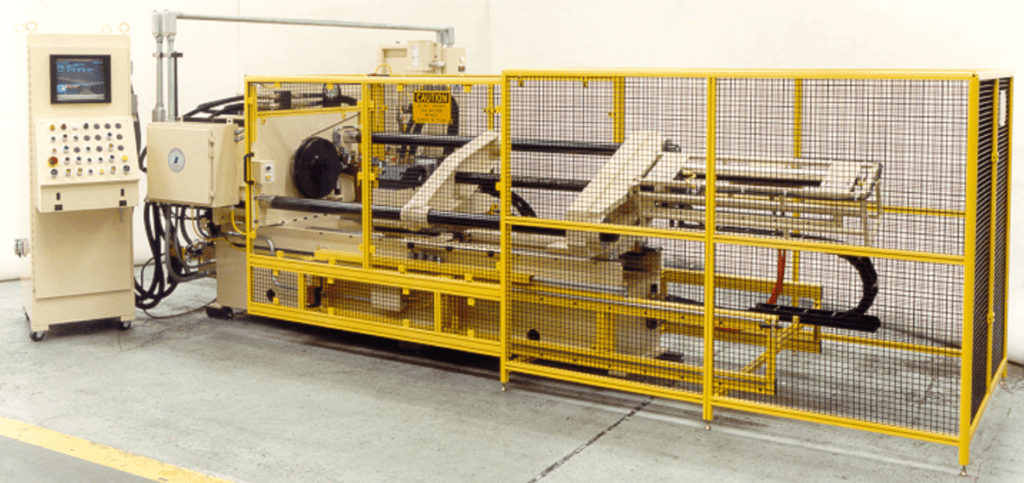

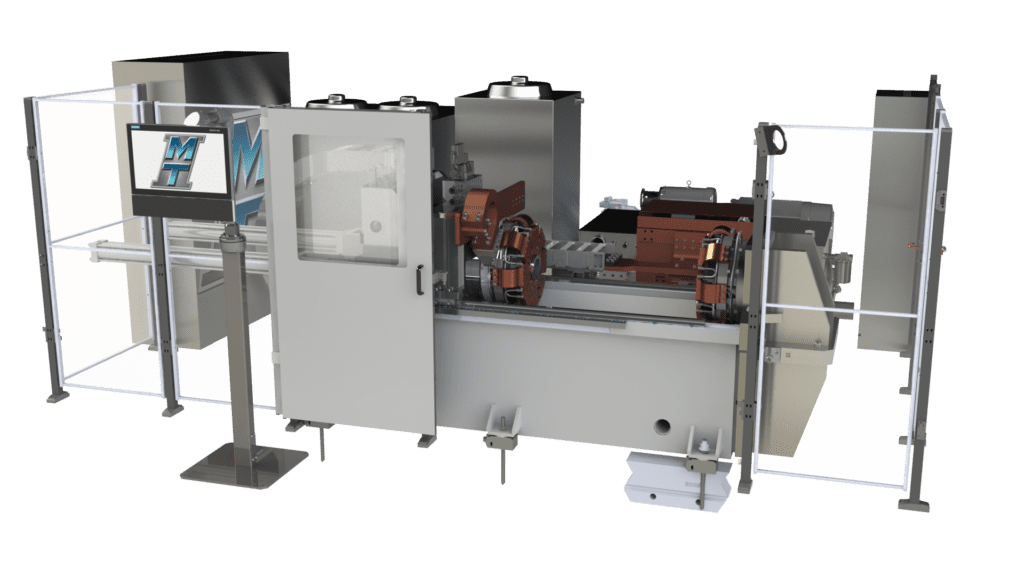

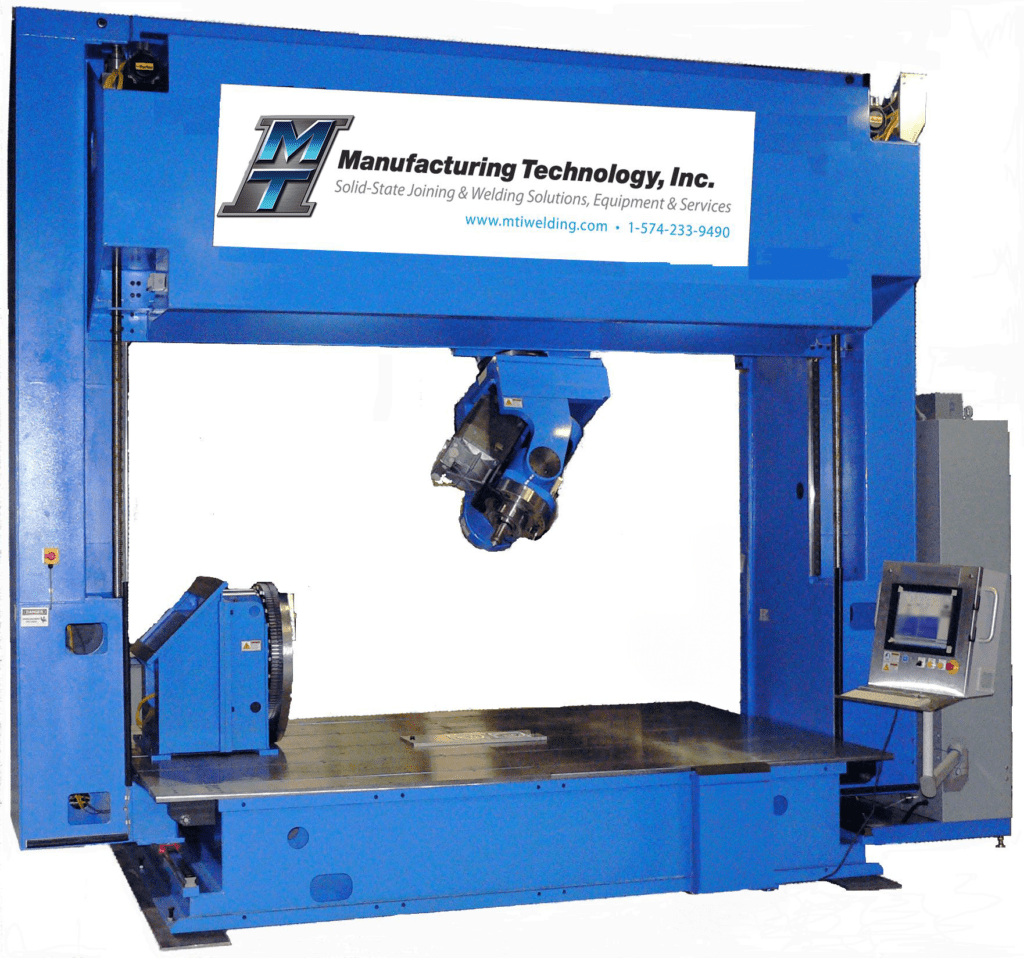

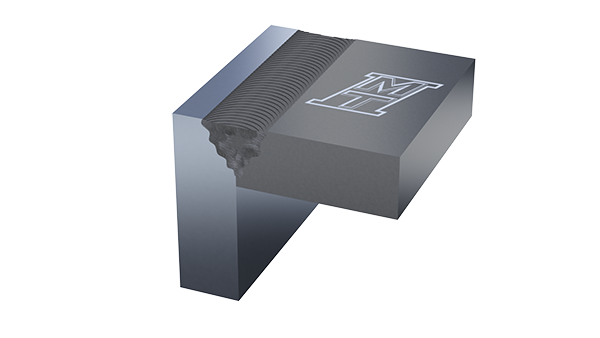

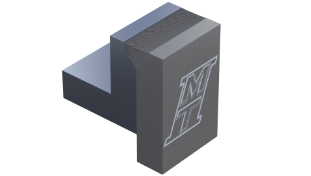

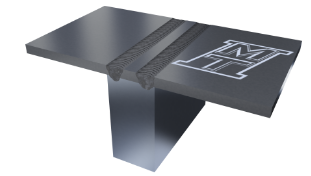

Linear Friction Welding

An Advanced Technique for Complex Challenges

Linear friction welding is a specialized process that is providing new and robust solutions for unique applications.

Linear Friction Welding

An Advanced Technique for Complex Challenges

Linear friction welding is a specialized process that is providing new and robust solutions for unique applications.

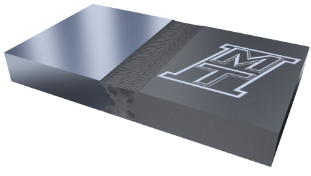

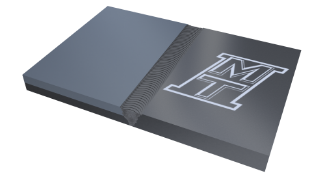

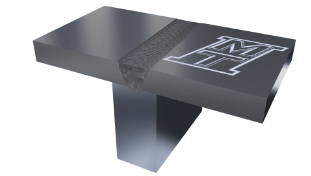

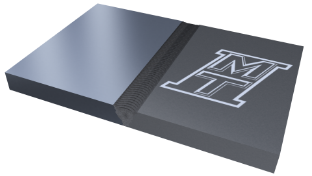

Friction Stir Welding

Tackle Emerging Challenges with Ease

Friction Stir Welding (FSW) is gaining momentum in the automotive and aerospace industries for its unique abilities.

Friction Stir Welding

Tackle Emerging Challenges with Ease

Friction Stir Welding (FSW) is gaining momentum in the automotive and aerospace industries for its unique abilities.

Five friction welding technologies that will change everything.

Is friction welding right for

your project?

Friction Welding is a diverse and adaptive process that can be used for many applications across several industries. As a solid-state joining process, Friction Welding offers a range of benefits and advantages as opposed to other welding techniques. It’s a proven and trusted process for many Tier 1 suppliers and OEMs. If you’re unsure of where to start, let us take it from here.

Low Force Friction Welding

Increase Precision at a

Fraction of the Force

An optimized form of traditional friction welding, Low Force

Friction Welding touts smaller and smoother flash, faster

cycle times, and reduced machine size.

Low Force Friction Welding

Increase Precision at a Fraction of the Force

An optimized form of traditional friction welding, Low Force Friction Welding touts smaller and smoother flash, faster cycle times, and reduced machine size.

Inertia Friction Welding

Scaling Up

Inertia is a subset of the Rotary Friction Welding process and allows for the scalability of applications.

Inertia Friction Welding

Scaling Up

Inertia is a subset of the Rotary Friction Welding process and allows for the scalability of applications.

Direct Drive Friction Welding

The Legacy Process

Direct Drive is a subset of the Rotary Friction Welding process and is the original friction welding technology.

Direct Drive Friction Welding

The Legacy Process

Direct Drive is a subset of the Rotary Friction Welding process and is the original friction welding technology.

Linear Friction Welding

An Advanced Technique for Complex Challenges

Linear friction welding is a specialized process that is providing new and robust solutions for unique applications.

Linear Friction Welding

An Advanced Technique for Complex Challenges

Linear friction welding is a specialized process that is providing new and robust solutions for unique applications.

Friction Stir Welding

Tackle Emerging Challenges with Ease

Friction Stir Welding (FSW) is gaining momentum in the automotive and aerospace industries for its unique abilities.

Friction Stir Welding

Tackle Emerging Challenges with Ease

Friction Stir Welding (FSW) is gaining momentum in the automotive and aerospace industries for its unique abilities.

Check Your Material Combination & Geometry

Can Your Application Be Friction Welded?

Compatible Welds

|

Not Seeing Your Combination Of Materials?

That doesn’t mean it can’t be done. Many of our material combinations are also proprietary. That’s why several of our customers use MTI’s in-house metallurgy lab, which will test your materials for strength and durability to see if friction welding is the right process for you.

Please note Weld strength is dependent on materials & geometry.

Joint Geometries

Friction Welding can join a wide range of part geometries

Let’s talk about the specifics of your project:

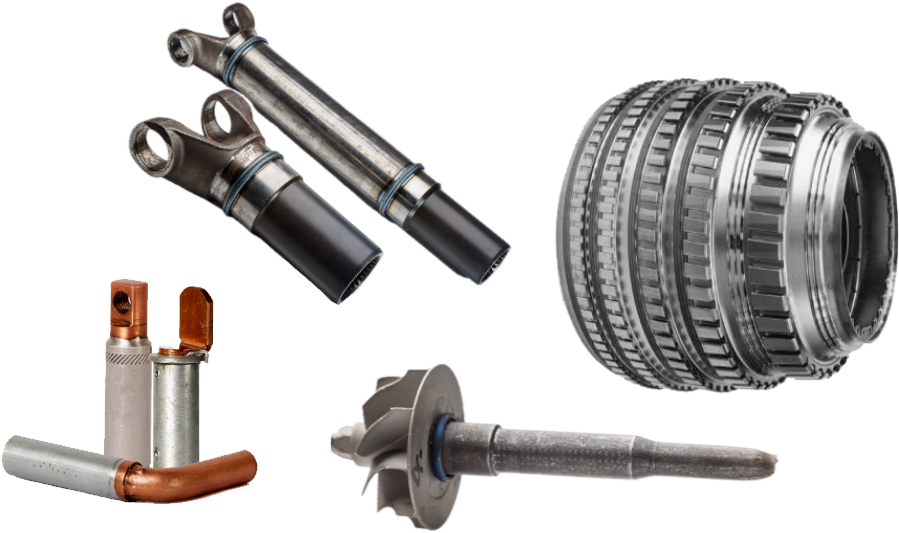

Explore Our Sample Parts

View our sample friction welded parts catalog to uncover applications that might be right for your next project.

Explore Our Sample Parts

View our sample friction welded parts catalog to uncover applications that might be right for your next project.

Our Commitment

Quality is at the core of our ingenuity

MTI brings the highest possible degree of safety and quality, whether it’s a part we’re welding or a machine we’re building. We are equipped to produce parts for the most sensitive environments and exacting standards.

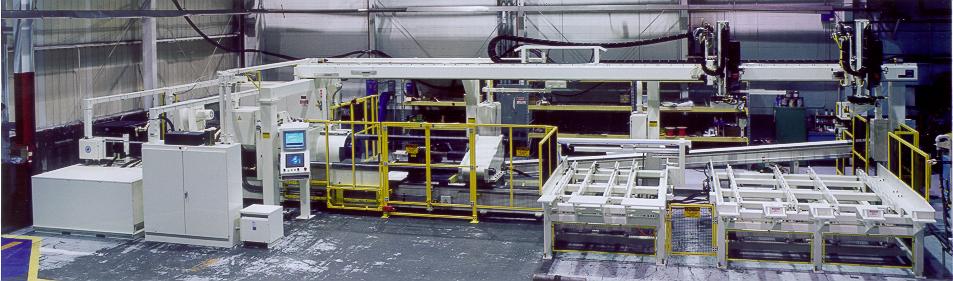

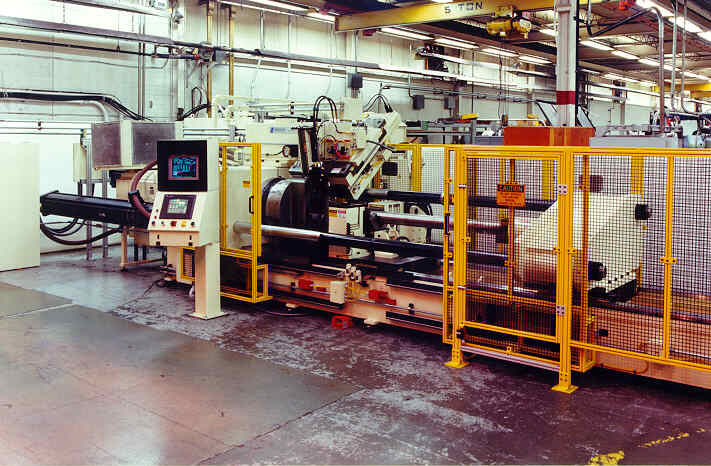

Contract Friction Welding

Contract Friction Welding

We don’t just build friction welders – we operate them, too. When you partner with either of our US or UK Contract Friction Welding teams, we will handle your project from start to finish on our state-of-the-art friction welding machines. Whether you need one part every year or one part every minute, we are here to help you reach your production goals across the globe.

Friction Welding Machines

Explore MTI’s wide range of friction welding and solid-state joining solutions.

ALL MAINSTREAM AEROSPACE ENGINE MANUFACTURERS UTILIZE & TRUST MTI-BUILT FRICTION WELDERS FOR THEIR CRITICAL COMPONENTS

MANUFACTURERS UTILIZE & TRUST MTI-BUILT FRICTION WELDERS FOR THEIR CRITICAL COMPONENTS

MANUFACTURERS UTILIZE & TRUST MTI-BUILT FRICTION WELDERS FOR THEIR CRITICAL COMPONENTS

MANUFACTURERS UTILIZE & TRUST MTI-BUILT FRICTION WELDERS FOR THEIR CRITICAL COMPONENTS

MANUFACTURERS UTILIZE & TRUST MTI-BUILT FRICTION WELDERS FOR THEIR CRITICAL COMPONENTS

ALL MAINSTREAM AEROSPACE ENGINE MANUFACTURERS UTILIZE & TRUST MTI-BUILT FRICTION WELDERS FOR THEIR CRITICAL COMPONENTS

MANUFACTURERS UTILIZE & TRUST MTI-BUILT FRICTION WELDERS FOR THEIR CRITICAL COMPONENTS

WE SERVE THE INDUSTRIES THAT SHAPE THE WORLD

Underground, on the surface, and in the skies.

Friction Welding, in all of its forms, is used in a wide range of industries. At the forefront of innovation, MTI offers end-to-end Friction Welding solutions for virtually any industry.

Learning Center

Case Studies

Videos

Whiteboard Wednesday

Whiteboard Wednesday

Get the information you need, before you need it — free and straight to your inbox from industry experts.

MTI White Papers

FWT: A cost-effective joining solution for the automotive industry

In the following pages, we will outline the benefits of friction welding, define the different types of friction welding, and describe the friction welding process. We’ll also mention current issues faced by the automotive industry. And finally, we’ll show how FWT is an effective tool to overcome these challenges and achieve manufacturing goals.