Aerospace Machines

Friction welding machines designed with the aerospace industry in mind. Explore the capabilities and possibilities of MTI’s line of aerospace friction welders.

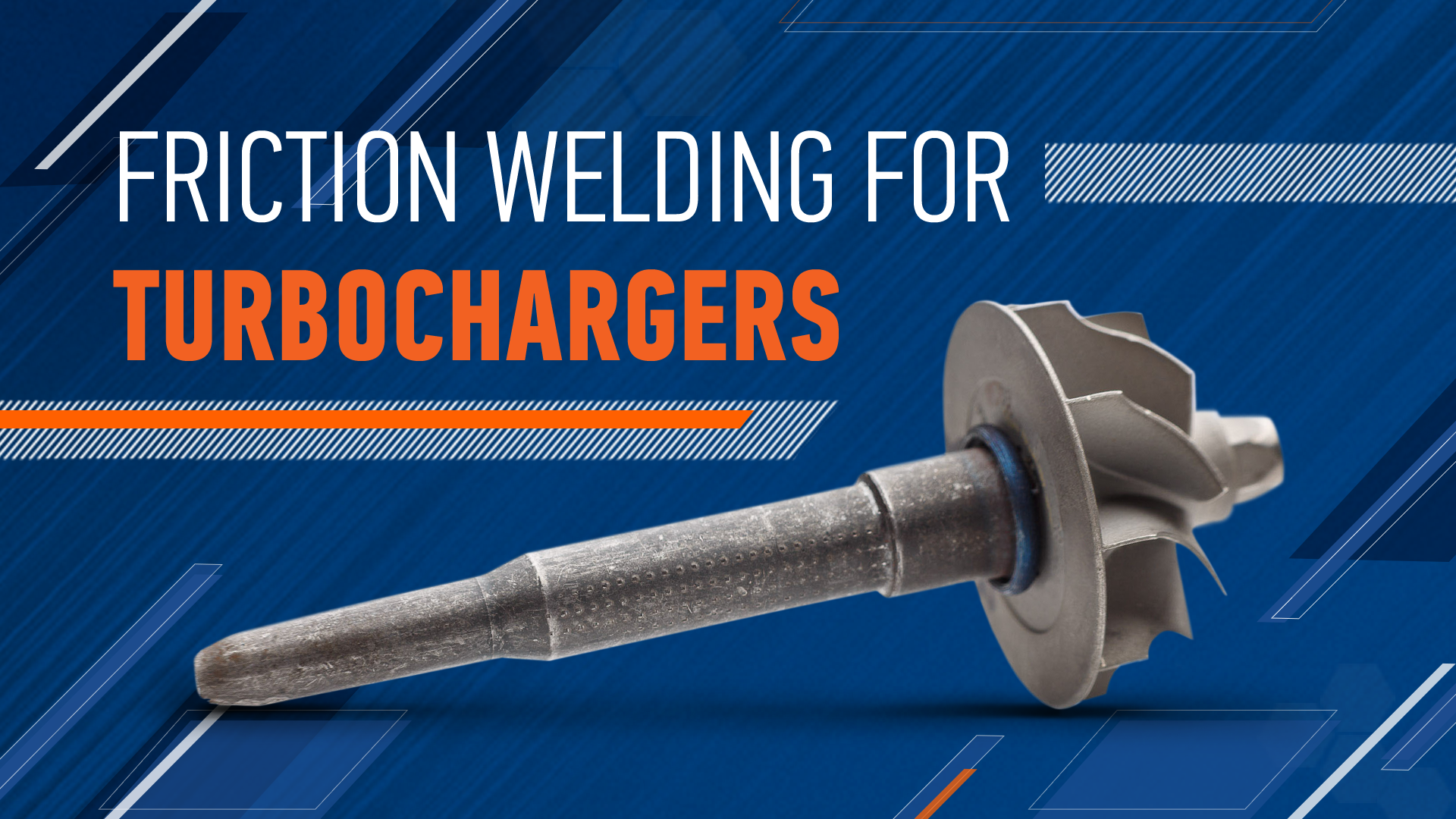

Sample Parts

Solutions that make it easy to select the right friction welding technology

| Application | Low compression titanium rotor assembly |

| Materials | Titanium |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Tube to rotor assembly |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Cluster gear |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Cluster gear cross section |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

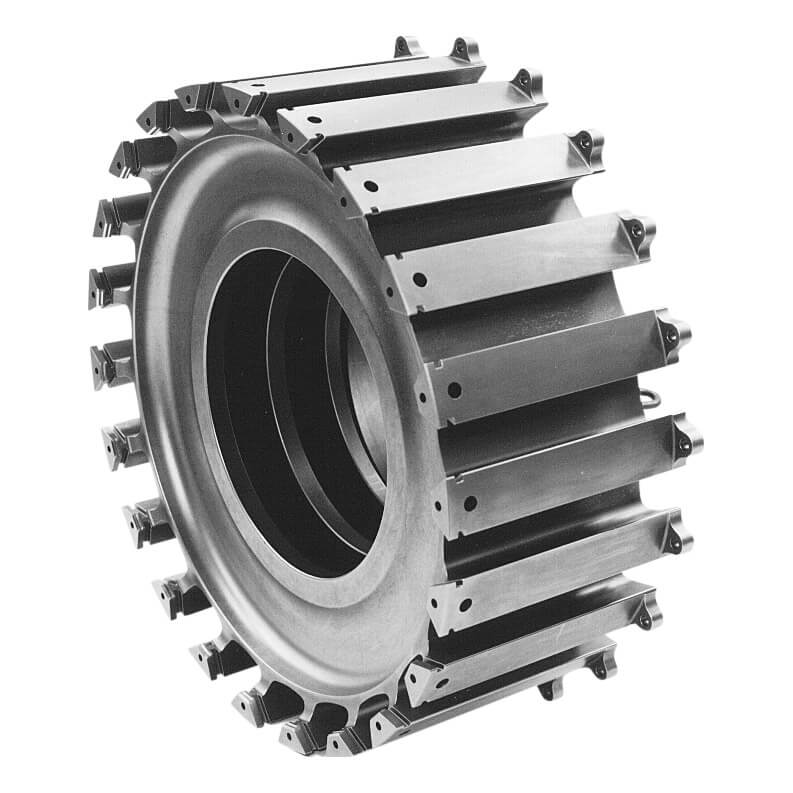

| Application | Fan blade rotor |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Disk |

| Application | Jet engine compressor rotor - as welded |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Landing gear drag brace |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Landing gear component |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Jet engine component - as machined |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Extension welded to four-blade propeller hub forging |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Bosses welded to accumulator housing |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Military jet engine compensating shaft - as welded |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Forged clevis to tubing for manufacture of ball screw. Actuates swing wing on F-14 fighter aircraft. |

| Materials | Steel - Maraging |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Fan shaft for military jet engine |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Commercial jet engine fan shaft - as welded |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Military jet engine fan shaft, cross-section - as machined |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Left: Stator vane root weld - as machined, Center: Stator vane root weld - with flash removed, Right: Stator vane root weld - as welded. |

| Materials | Titanium |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Ball screw actuator |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Bar |

| Application | Bi-metallic aircraft rivets |

| Materials | Titanium |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Stator vane adjustor lever |

| Materials | Titanium |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Aircraft hook bolts |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Lightweight piston for aircraft pump |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Aerospace heat pipe |

| Materials | Aluminum |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

Ready to make your ideas take flight?

We’re here to help make it happen.

Watch How It’s Done

Aerospace Videos

Need to see how we do it? Watch our videos to learn everything you wanted to know about the friction welding process, all in one place.

Aerospace

Show All

Machine Talk Blog

The welding solution to the challenges you're facing may be one click away

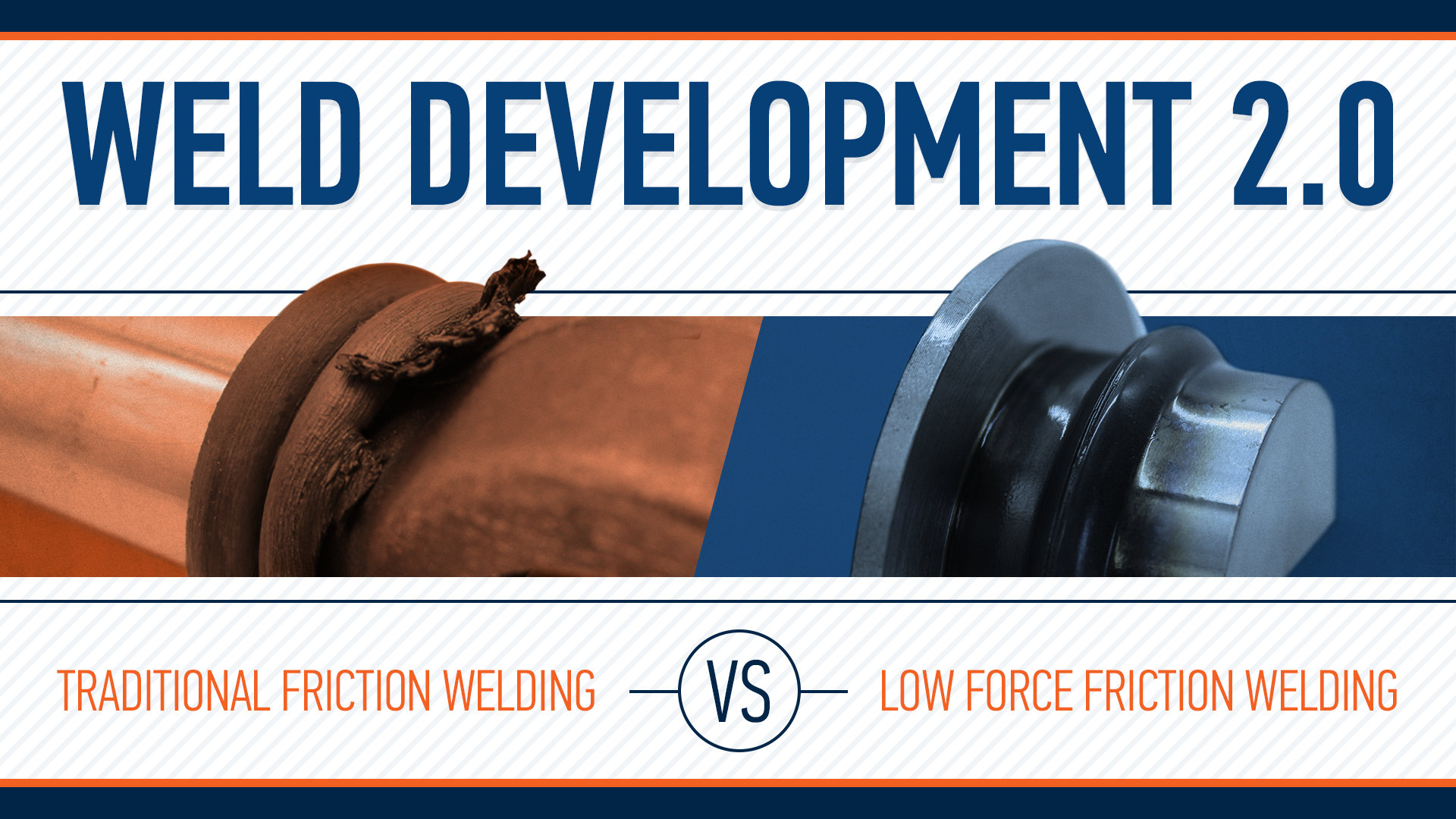

Weld Development 2.0

Get the most out of your manufacturing process with MTI's newest Weld Development package.

New Tri-Mode Rotary Friction Welder

MTI has added a new tri-mode Rotary friction welding machine to our Manufacturing Services location! Keep reading to learn if its right for your project.

MTI UK

MTI UK  FWT

FWT