Friction welding solutions for the Oil and Gas industry

Friction welding’s proven reliability is coupled with such process advantages as being clean, fast, consistent, and free of operator-induced error. This makes friction welding one of the leading methods of joining flanges to valve bodies, drill pipe, high-pressure hose couplings, and manifold tubes.

Harbison-Fischer, a manufacturer of oil well pumping equipment, was having trouble producing a key pump part in a timely and cost-efficient manner. After teaming up with MTI, we applied our partnership process along with our experience in oil field applications.

This led to developing a friction welding machine that solved their problem by manufacturing the part with much higher quality while also saving them time and money. The experience also resulted in creating other innovations for this and other industries as well.

Learn More

| Application | High-pressure valve body. Forged flanges welded to forged valve body. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Disk |

| Application | Butterfly valves. Wrought stainless steel extension welded to investment cast stainless steel butterfly valver: Stator vane root weld - with flash removed, Right: Stator vane root weld - as welded. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | High-pressure valve body weld cross-section |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Geological core drill - end blank welded to tubing |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Bar |

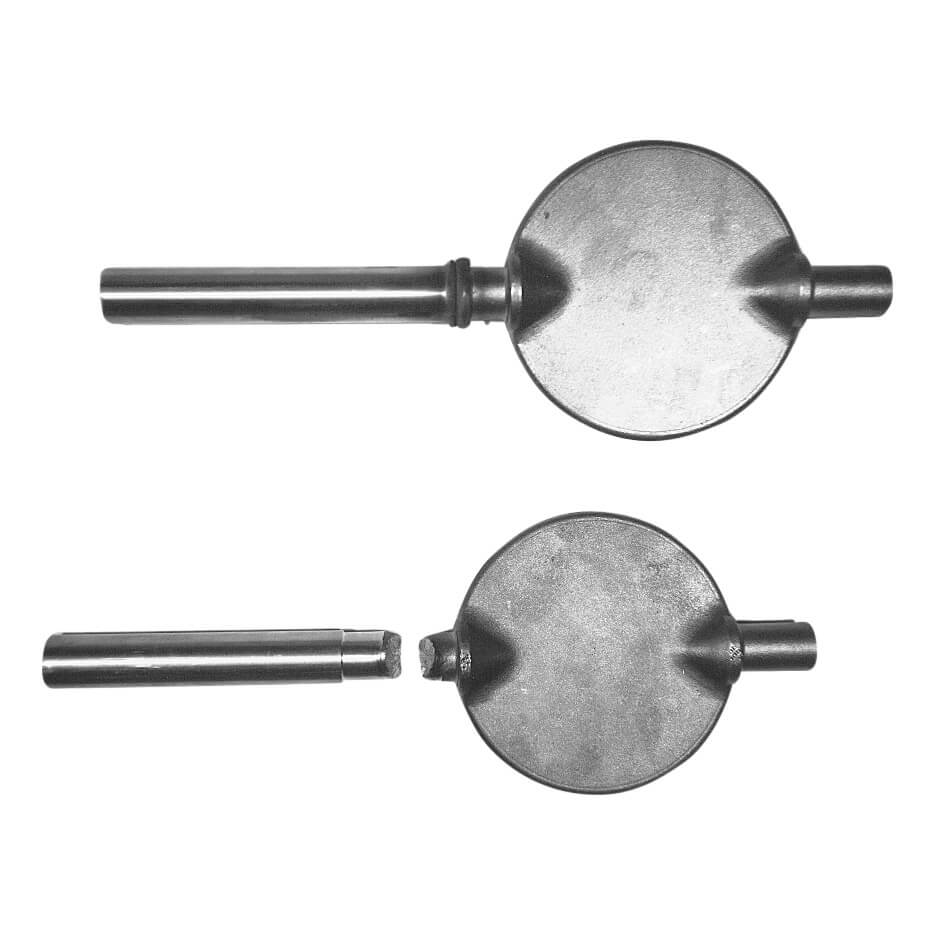

| Application | Sucker rod. Threaded end connector welded to forged sucker rod. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Bar |

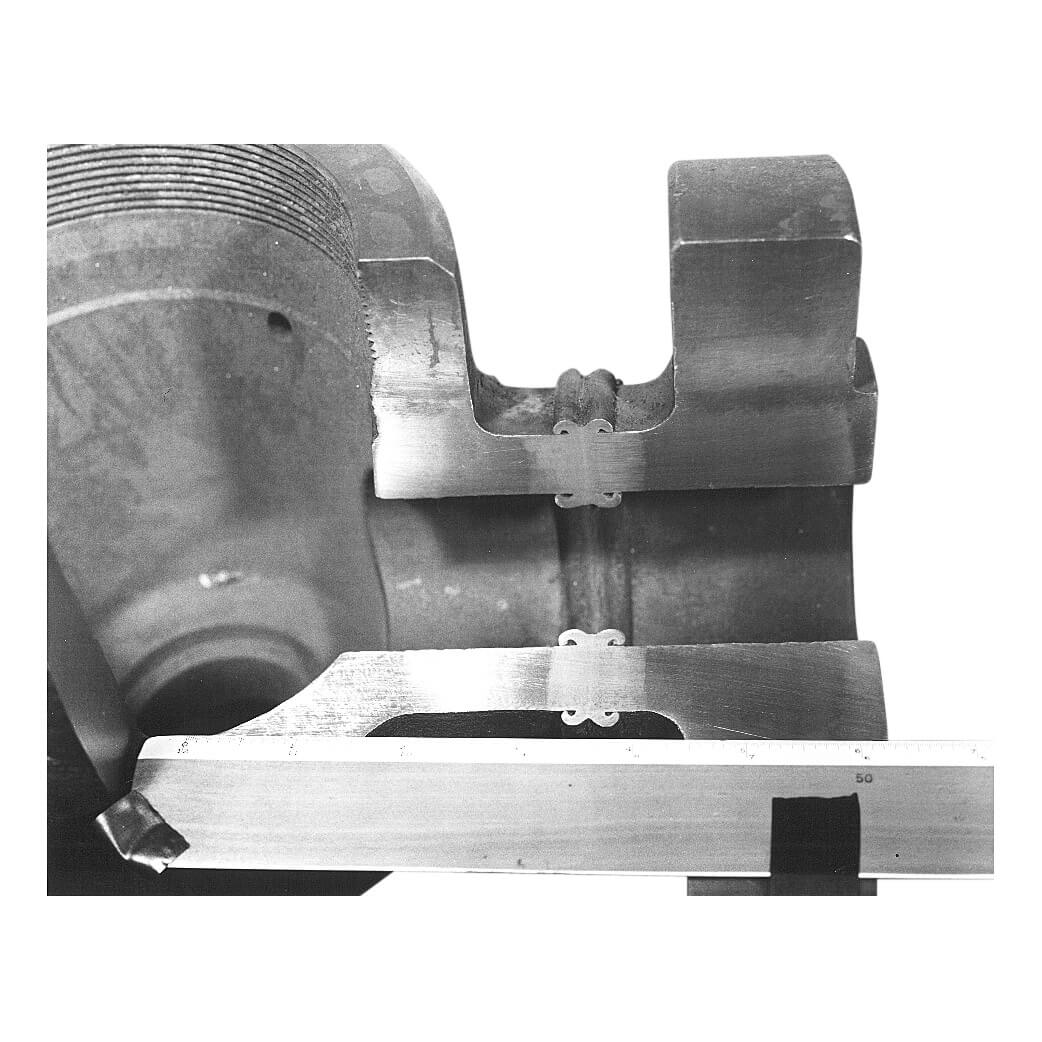

| Application | Oil well drill pipe. Close-up of tooljoint to drill pipe weld - female end. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Oil well drill pipe. Close-up of tooljoint to drill pipe weld - male end. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Disk |

| Application | Oil well head manifold tubing cross-section |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

Since a typical string of drill pipe can be three to four miles long, composed of 30-foot sections, weld integrity is a must in the oil field drilling industry. The friction welds support the lower drill stem assembly (made up of other drill pipes, drill collars, and the drilling bit) and transmit the rotary torque needed for drilling. Friction welding produces a metallurgical bond strong enough to take the high torque and highly loaded rotary tension due to directional drilling.

Explore Our Process

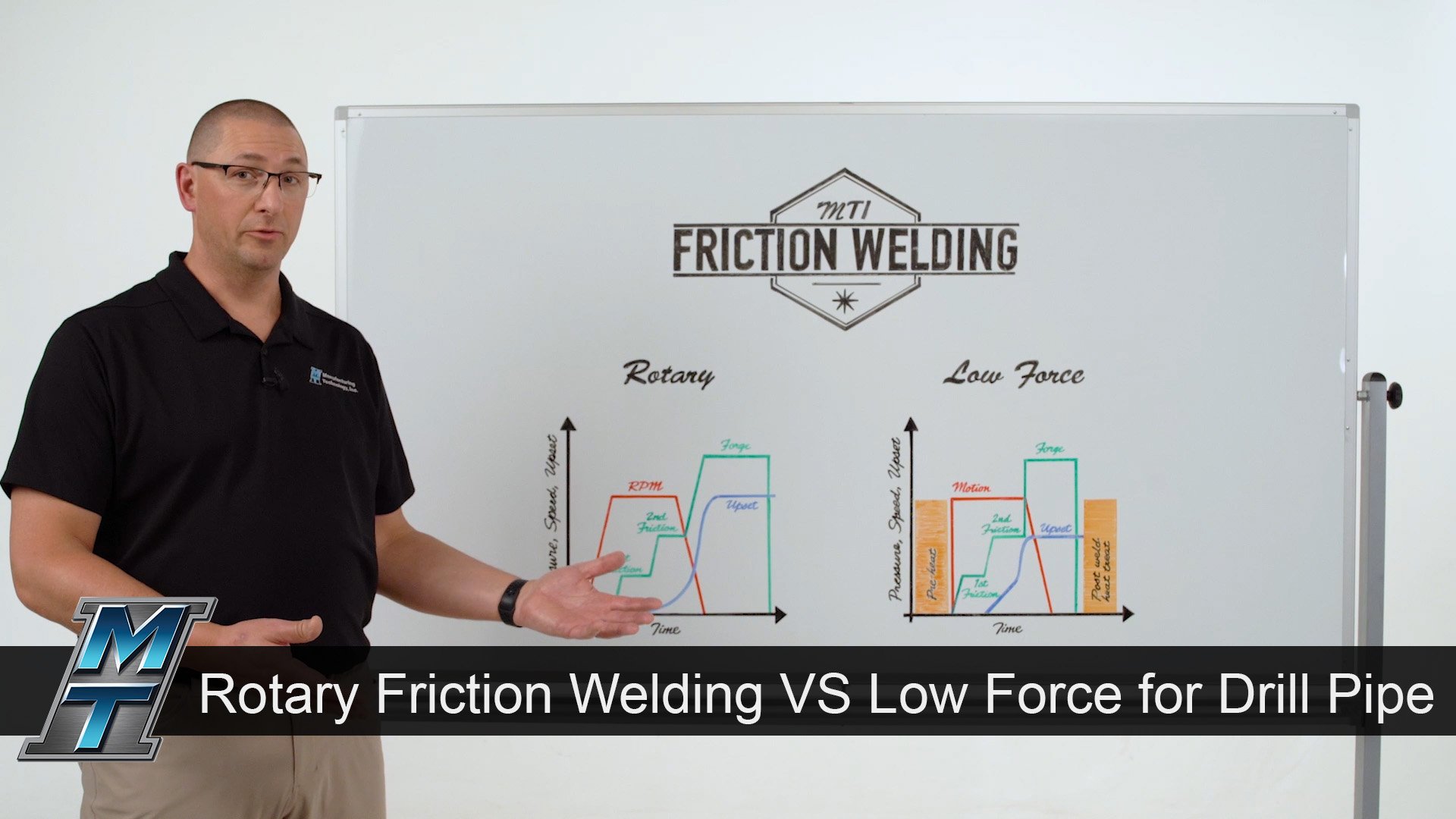

Get the most out of your manufacturing process with MTI's newest Weld Development package.

MTI has added a new tri-mode Rotary friction welding machine to our Manufacturing Services location! Keep reading to learn if its right for your project.

MTI UK

MTI UK  FWT

FWT