Friction welding solutions for the Consumer Products industry

From staying in shape to staying in touch, friction welding plays an enormous role in consumer products. Friction welding machines produce key parts for barbells, cell phones, computer monitors, golf clubs, and countless other products people use every day. Improving aesthetics, providing strength, delivering cost savings – these are just a few of the many benefits friction welding produces.

Friction Stir Welding not only adds new improved weld strength and durability to consumer products but can significantly improve the product’s aesthetic quality while eliminating material and processing steps associated with arc based methods of welding. Gone are the large, thick “weld pool” patterns. Residual flash if formed at all during the FSW process, is a fraction of what is formed during arc based methods and can be removed within the same machine pass with a special clean up tool. New Linear Friction welding tooling and techniques allow for the assembly of a complete product component at one time, and in just seconds, while generating minimal heat and few external areas to “clean up” machine to near net shape. Final products can use a minimalist design approach, coupled with a secure, durable, tamper resistant enclosure, leaving consumers wondering “How did they assemble that?”

EXPLORE OUR PROCESS

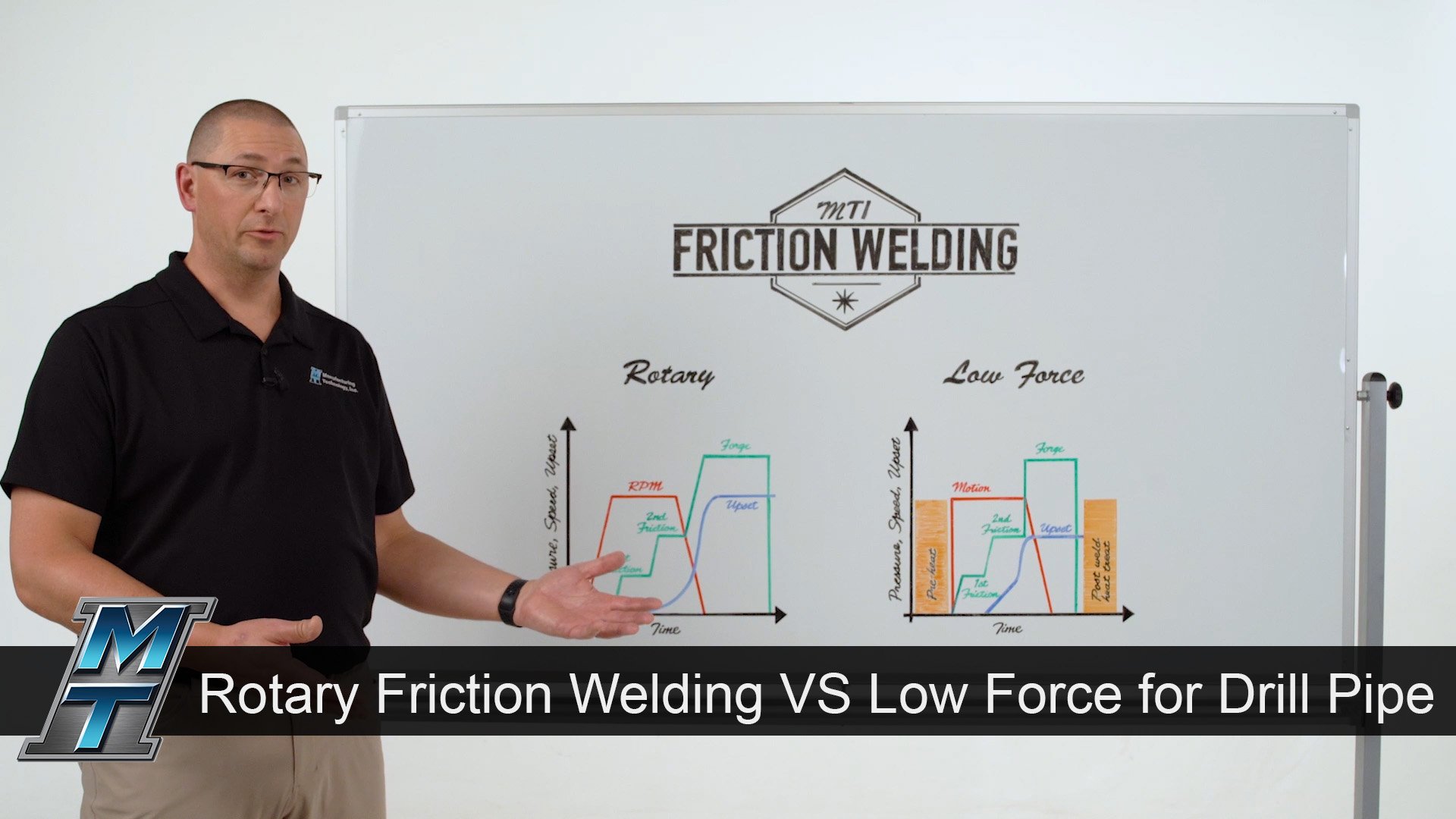

Get the most out of your manufacturing process with MTI's newest Weld Development package.

MTI has added a new tri-mode Rotary friction welding machine to our Manufacturing Services location! Keep reading to learn if its right for your project.

MTI UK

MTI UK  FWT

FWT