It’s an obstacle that many Aerospace providers face in the early stages of their projects: they’re limited by the amount of material they can use. This can be for a number of reasons – lightweighting goals, material costs, the list goes on. So, unsurprisingly, Element Materials Technology was not spared from this predicament when it was conceptualizing a component for one of its testing frames.

Element has 200 laboratories across the world and provides global testing, inspection, certification, and calibration services. Element, like MTI, offers its expertise to the Aerospace industry, so finding a joining partner that understands the regulations of air and space travel was crucial.

Tom Houtz, a Department Manager at one of Element’s labs in Ohio, was already familiar with inertia friction welding and knew MTI’s solid-state process would be a perfect match for Element’s part. The stronger weld joints, bimetallic capabilities and quicker cycle times produced by friction welding were especially attractive to Element. Those benefits helped lead to a successful final product.

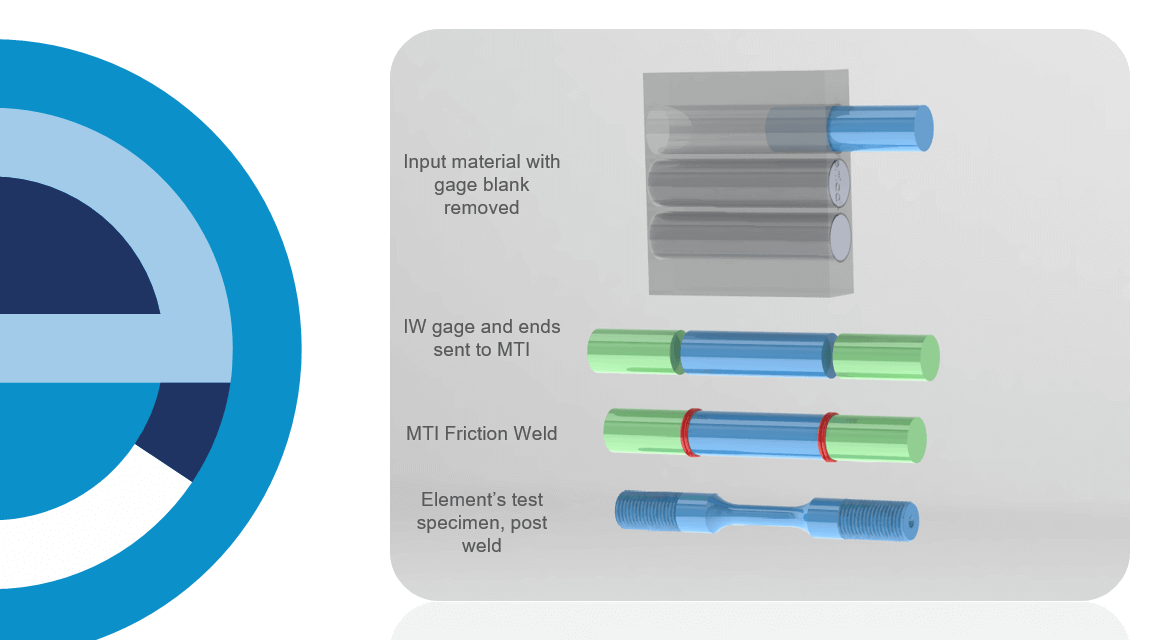

“We found that we could get around the limited materials by friction welding grips on the end of our components so they could fit on our test frames,” Houtz said.

Testing Frame Part Sample (Element Materials Technology)

Time was of the essence for this partnership — and that’s why MTI’s Manufacturing Services team stepped in to offer contract friction welding for Element’s parts. After Element sent the materials to MTI, the Manufacturing Services team was able to join the parts on MTI machines and ship the finished product to Element.

“The turn time was the most critical aspect of this partnership with Element,” MTI Inside Sales Coordinator Sherri Lotter explained. “Through good communication, we have done well with getting Element’s jobs in and out quickly.”

Houtz said MTI’s history with the Aerospace industry gave him and his team the confidence that MTI could deliver a quality product.

“We know MTI has worked with a lot of different Aerospace companies and we have really fostered a great relationship,” Houtz said.

Based on the success with this relationship, Element and MTI are now in discussions about transferring over more steps of the post-weld process to MTI so a majority of the project can be completed under one roof.

- Watch our White Board Wednesday video series to learn more about friction welding.

- Read more about how contract friction welding can help make your project more efficient.