If you’ve been following along with our Whiteboard Wednesday series, you could likely name several friction welding applications that you can see on the highway or in the sky on a fairly regular basis. However, there is another popular application that relies largely on friction welding, and because it does most of its work below the surface, you may never actually lay eyes on it.

In this episode of Whiteboard Wednesday, we’re taking a closer look at friction welding for drill pipe – particularly, we will be showcasing the benefits of our legacy technology and explore how our newest technology could even further improve on its successes.

When we talk about drill pipe, we can split that into three categories:

- Oil well drill pipe

- Water well drill pipe

- Rock drilling

ROTARY FRICTION WELDING AND DRILL PIPES

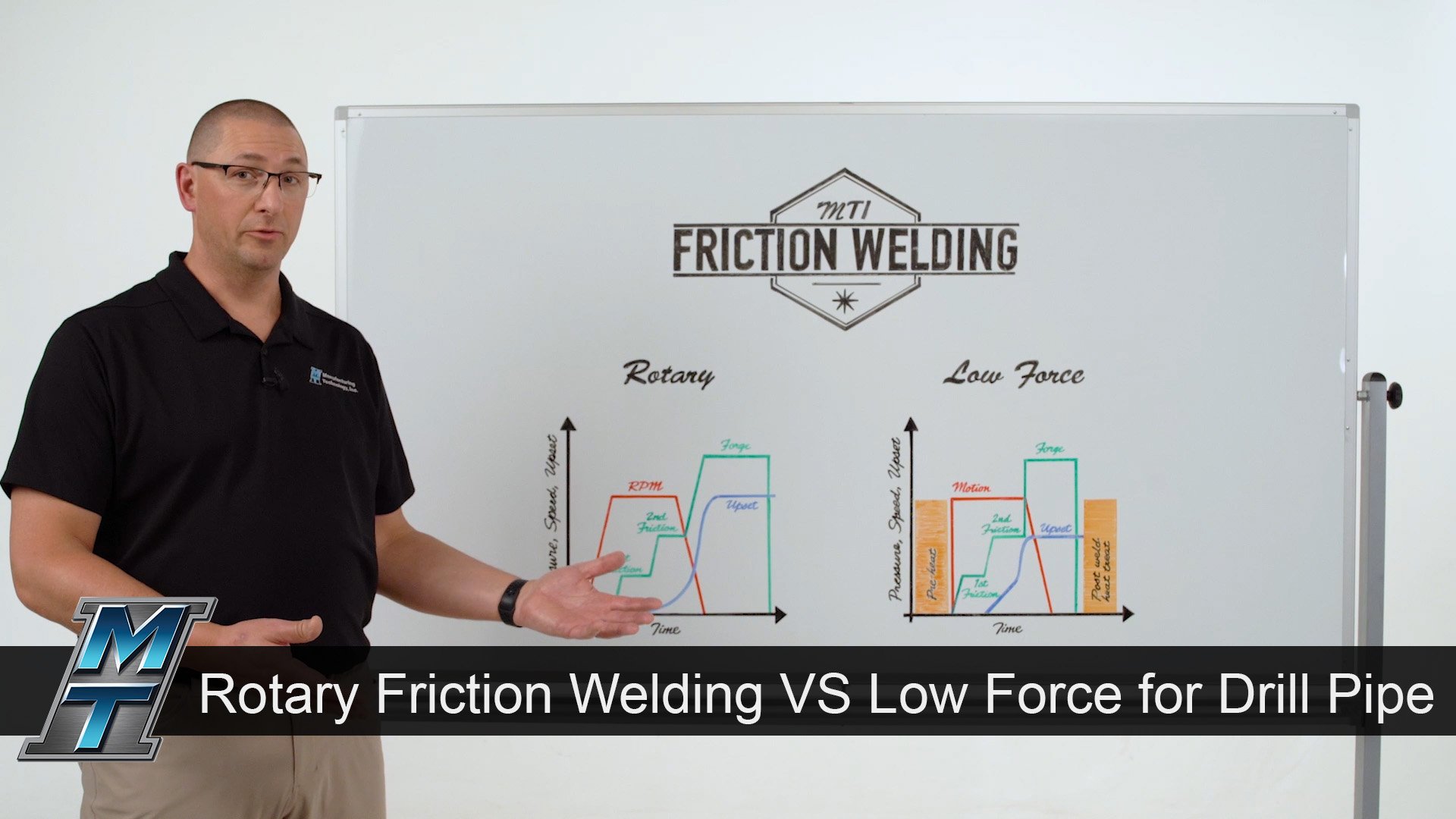

For decades, MTI has used Rotary Direct Drive and Inertia Friction Welding to join drill pipes.

Drill pipes – oil well pipes specifically – require Inertia friction welding due to the high energy needed for strong, successful welds because they’re made from hardenable steel. With Inertia friction welding, we use four times as much energy and twice as much load in order to be able to get the energy in and make sure we aren’t forming martensite at the end of the weld.

Let’s walk you through how the process works, step by step:

- We take the component that’s rotating and bring it up to the target RPM

- We bring on first friction pressure (this helps square up the interfaces and reduces the coefficient of friction so we can bring on a higher load without stalling the motor)

- We then begin the second friction phase, where the cycle time extends to add the extra energy and create more upset

- Finally, we take the speed back down to zero once the desired amount of upset is achieved to bring on the forge load

Let’s take a look at a traditional oil well drill pipe component. You can see that there is a lot of upset in this weld – note the large flash curls on the outside and inside.

With traditional friction welding, we will shear off the inner diameter (ID) flash for oil well applications – that ensures liquid flows smoothly and efficiently through the component. With rock drilling, there is a gas lancing operation to remove the ID flash. Because of the bulky flash formation, we are forced to design a component around the flash… but it doesn’t have to be that way.

Our newest technology, Low Force Friction Welding, can help us skip flash removal all together – read on how:

LOW FORCE FRICTION WELDING FOR DRILL PIPES

With Low Force Friction Welding, we add an element of preheat, meaning we are no longer getting it from the second friction phase. The preheat is added upfront – whether through induction or resistance.

We then shift into our motion profile, which can vary, based on the application.

We COULD choose to bring on a low load and go through first friction, second friction and forge… OR we can just bring on the forge load from the beginning. The versatility is one of the best things about Low Force Friction Welding!

Because we are adding the energy upfront, we don’t need a long cycle time or second friction phase to get the energy in. Because of this, we aren’t creating as much upset because the energy has been there since the beginning.

With Low Force Friction Welding, we can make fast welds with a low amount of upset, which changes the flash morphology – meaning flash removal may now be completely unnecessary.

Now let’s take a look at a component joined with Low Force Friction Welding. You’ll notice that instead of a large flash curl, we get just a small flash bulge on the ID and OD, which you may not need to remove at all.

A SPECIAL CONSIDERATION FOR OIL WELL DRILL PIPES

There’s something else that sets oil well drill pipes apart from other applications – the grain structure. When we get a large flash formation through traditional friction welding, the grain structure begins to change direction as it’s forming the upset. Therefore, you have the incoming part material that slowly upsets then gets pushed out into the flash curl, changing the direction.

If we were to have an acidic application, that acid starts to eat away at those end grains, reducing the life of the component.

Meanwhile, with Low Force Friction Welding, we just have a flash bulge, meaning we don’t have that end grain exposure, so we will have much better resistance to acidic applications.

THINKING BIG PICTURE

When considering Low Force Friction Welding – we encourage you to look at your entire manufacturing process to examine how you could save time and money.

Ask yourself these questions:

- How do the incoming parts come to the machine? Are they square? Are they clean?

- Do we want a low upset weld?

- Do we have to do ID or OD flash removal?

- Do we have to do a post-weld heat treatment because of the metallurgy?

Now, take a look at those questions again.

If Low Force eliminates the need to remove flash, for example, you can now produce a finished part on your welder without adding additional steps, freeing up time and space on your production floor.

LOW FORCE: IS IT RIGHT FOR ME?

Whether or not your company produces drill pipe, you may now be wondering whether Low Force would be a sensible investment for your next machine. Let us try it out for you!

MTI’s robust Weld Development process can walk you step-by-step through Low Force to show you how our new technology can optimize your part.

You’ll be with us each step of the way as we explore part design, test your material and parts and potentially design a machine for your company.

Begin your Low Force journey by contacting one of our knowledgeable sales engineers today!

Website: https://www.mtiwelding.com/

LinkedIn: https://www.linkedin.com/company/manufacturing-technology-inc/

YouTube: https://www.youtube.com/c/ManufacturingTechnologyIncMTIJoiningSolutions/videos