Friction welding is a solid state joining process. It’s actually a forging process: not a welding process. In the Friction Welding process we use relative motion and high force in order to create frictional heat at the weld interface. This heats the materials being joined to the point where they will plasticize without melting. The result is molecular intermixing at the weld interface and a forged quality joint.

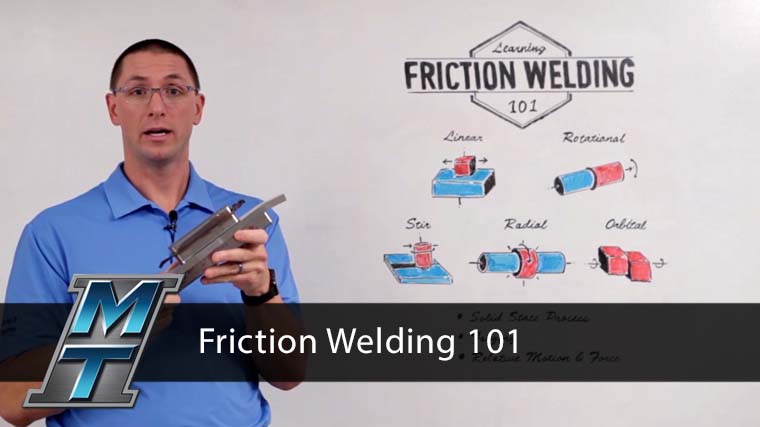

There are five types of friction welding: Linear, Rotary, and Stir are the most common used in parts applications, while Radial and Orbital are less common. The different types of friction welding refer to the different types of relative motion. For example, with Linear Friction Welding – one piece is held stationary while the other oscillates back and forth on a linear path. This simple linear motion enables parts with varying geometries at the weld interface to be joined.

For Rotary Friction Welding, one piece is stationary while the other is rotating. The rotating piece needs to be symmetric around its rotating axis in order to be able to make this weld.

With Friction Stir Welding, both parts are stationary, so very large, long, or thin parts, such as sheet metal or an extrusions can be joined. A rotating, non-consumable pin tool provides the force and motion required to generate heat for forging. As the pin tool traverses along the seam between the pieces, it leaves a forged seam in its path.

Radial Friction Welding and Orbital Friction Welding are much less common applications of Friction Welding. In Radial Friction Welding, a rotating ring or collar is compressed onto the outside diameter of a tube or a bar. With Orbital Friction Welding, two parts orbit around their center axis in order to create that relative motion.

The bottom line is that MTI has a Friction Welding solution for almost all of your part geometries enabling you to take advantage of this solid-state joining technique.

FIND YOUR SOLUTION

MTI serves a variety of industries and applies friction welding to thousands of applications including global aerospace companies, the U.S. military, and large agricultural and trucking companies. And we’re prepared to find a solution for your needs. We’ll build a machine for that makes your part, we’ll make the part for you, or we’ll help you make the part even better. Contact us to get started.