Direct Drive Friction Welders

MTI Rotary Friction Welding Machines – Precision, Performance, and Reliability

Explore MTI’s most popular Rotary friction welders for industry. Select a machine below for detailed information and specifications.

What is Rotary Friction Welding?

Rotary Friction Welding is a solid-state joining process in which one part in high-speed rotation is pressed against a stationary part. The friction created by their contact heats them enough to forge together below the melting point. This friction welding method is used in multiple industries for superior weld quality, such as aerospace, defense, and construction.

Gain the Advantage of MTI Rotary Welding Machines

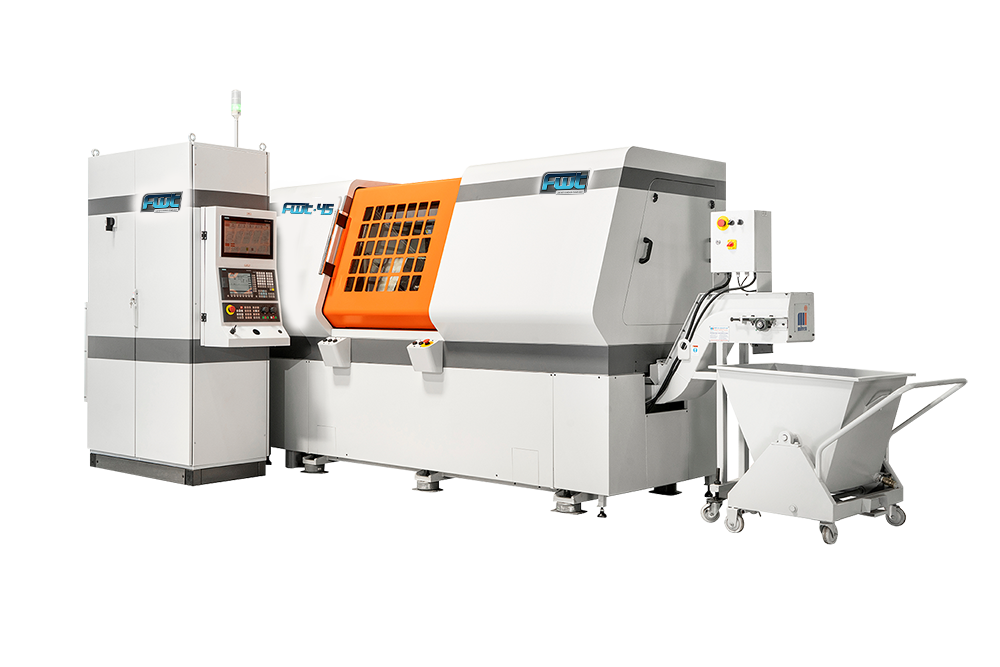

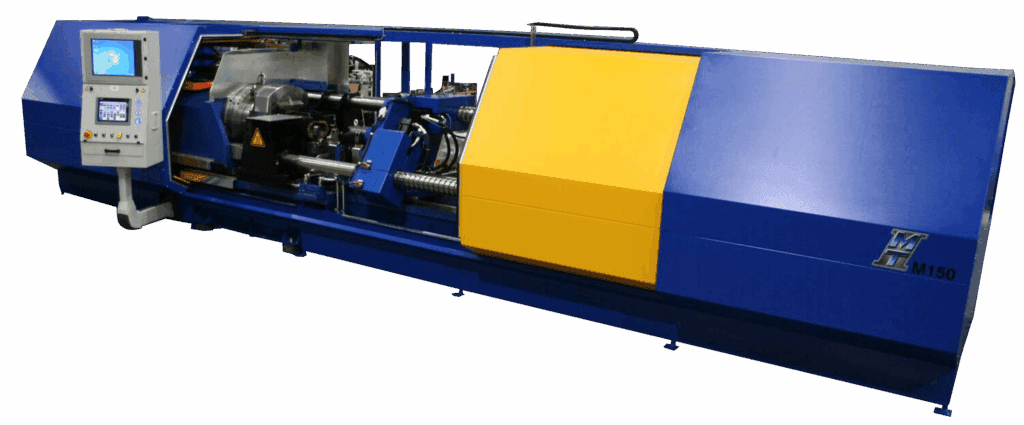

MTI’s direct drive rotary friction welding machines combine precision, efficiency, and innovation. Our solid-state joining process ensures strong, defect-free welds. At the same time, you reap the benefits of maximizing production efficiency and cost savings.

Smart Automation & Production Efficiency

Easy to Automate for Seamless Production

A standard machine design with a straightforward and streamlined exterior, MTI’s friction welders are user-friendly for efficient production in various industries.

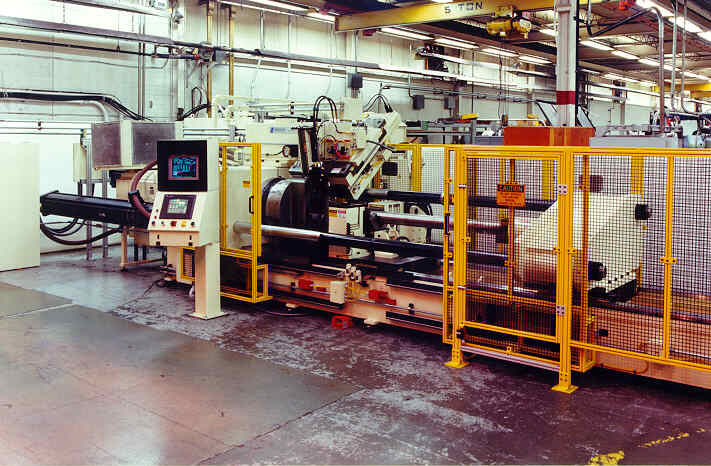

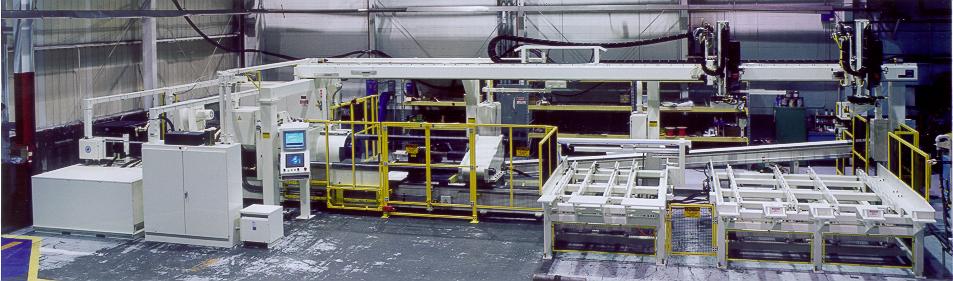

Fully and Semi-Automated Systems for Flexibility

Our semi-automated and fully automated machines can be incorporated into an existing manufacturing line or an isolated production cell for efficient welding applications free from operator errors.

Automatic Backstop Adjustment for Precise Welding

An automatic backstop adjustment reduces component changeover times, optimizing part stick out and maintaining precision across different parts and applications.

Reduced Cycle Time with Automatic Doors and Light Curtain

MTI’s friction welding machines use automatic doors and light curtains to optimize cycle time and efficient production without compromising welding force or material control whilst ensuring operator safety.

Efficient Chip Conveyor for Material Removal

The built-in chip conveyor option efficiently removes excess material from the welding machine, keeping the production area clean and improving overall manufacturing efficiency.

Cost Reduction Through Efficient Processes

MTI’s friction welding direct drive machines help manufacturers achieve maximum cost savings.

Easy to Automate for Seamless Production

A standard machine design with a straightforward and streamlined exterior, MTI’s friction welders are user-friendly for efficient production in various industries.

Fully and Semi-Automated Systems for Flexibility

Our semi-automated and fully automated machines can be incorporated into an existing manufacturing line or an isolated production cell for efficient welding applications free from operator errors.

Automatic Backstop Adjustment for Precise Welding

An automatic backstop adjustment reduces component changeover times, optimizing part stick out and maintaining precision across different parts and applications.

Reduced Cycle Time with Automatic Doors and Light Curtain

MTI’s friction welding machines use automatic doors and light curtains to optimize cycle time and efficient production without compromising welding force or material control whilst ensuring operator safety.

Efficient Chip Conveyor for Material Removal

The built-in chip conveyor option efficiently removes excess material from the welding machine, keeping the production area clean and improving overall manufacturing efficiency.

Cost Reduction Through Efficient Processes

MTI’s friction welding direct drive machines help manufacturers achieve maximum cost savings.

Precision, Versatility & User Experience

Flash Removal Systems for Streamlined Operations

MTI’s direct drive friction welding machines have single-axis, double-axis, and multi-tool flash removal systems to eliminate unnecessary pre- or post-weld machining.

Self-Centering Chuck Accessories for Faster Change-overs

With two-jaw and three-jaw chuck accessories, our rotary friction welding machines reduce change-over time, increasing the ability to weld multiple parts with precision.

Secure User Administration with ID and Password Access

MTI ensures secure user administration through identification ID and password authentication, providing controlled access to operators and maintaining machine control integrity.

Minimal Maintenance for Maximum Uptime

Designed for durability, MTI’s direct drive welding machines provide a high-production range with minimal maintenance.

Diverse Material Combination Capabilities

Our rotary friction welders can join dissimilar materials for manufacturing possibilities across industries.

Ergonomically Designed for Operator Comfort & Safety

Designed with ergonomic controls for operator safety, comfort, and ease of operation.

Flash Removal Systems for Streamlined Operations

MTI’s direct drive friction welding machines have single-axis, double-axis, and multi-tool flash removal systems to eliminate unnecessary pre- or post-weld machining.

Self-Centering Chuck Accessories for Faster Change-overs

With two-jaw and three-jaw chuck accessories, our rotary friction welding machines reduce change-over time, increasing the ability to weld multiple parts with precision.

Secure User Administration with ID and Password Access

MTI ensures secure user administration through identification ID and password authentication, providing controlled access to operators and maintaining machine control integrity.

Minimal Maintenance for Maximum Uptime

Designed for durability, MTI’s direct drive welding machines provide a high-production range with minimal maintenance.

Diverse Material Combination Capabilities

Our rotary friction welders can join dissimilar materials for manufacturing possibilities across industries.

Ergonomically Designed for Operator Comfort & Safety

Designed with ergonomic controls for operator safety, comfort, and ease of operation.

Benefits of MTI's Direct Drive Technology

MTI’s advanced friction welding machines ensure long-lasting durability in automotive, aerospace, and industrial applications. With the proven solid-state joining process, our MTI machines offer several advantages over traditional joining methods.

Superior Weld Quality for

Critical Applications

MTI’s rotary friction welding machines deliver forged-quality welds that outperform traditional welding machines like MIG and TIG, making them ideal for safety-critical applications.

Faster Weld Cycles for

Increased Productivity

As a solid-state joining process, MTI’s friction welding machines are twice to 100 times faster than conventional welding processes, completing jobs in seconds.

Bimetallic Joining for Diverse

Material Combinations

MTI’s friction welding machines enable the solid-state joining process of dissimilar metals, such as copper to aluminum, making them the most reliable solution for bimetallic applications in high-performance manufacturing.

Our Commitment

Quality is at the core of our ingenuity

MTI brings the highest possible degree of safety and quality, whether it’s a part we’re welding or a machine we’re building. We are equipped to produce parts for the most sensitive environments and exacting standards.