Types of Friction Stir Welding Tools

Explore the Different Types of Friction Stir Welding Tools

Friction Stir Welding (FSW) Tools

Friction Stir Welding (FSW) tools play a critical role in determining weld quality, heat input, and surface finish, especially when joining challenging metals and alloys. The right non-consumable FSW tools are essential for a successful implementation because they directly impact the strength, efficiency, and consistency of your welding process.

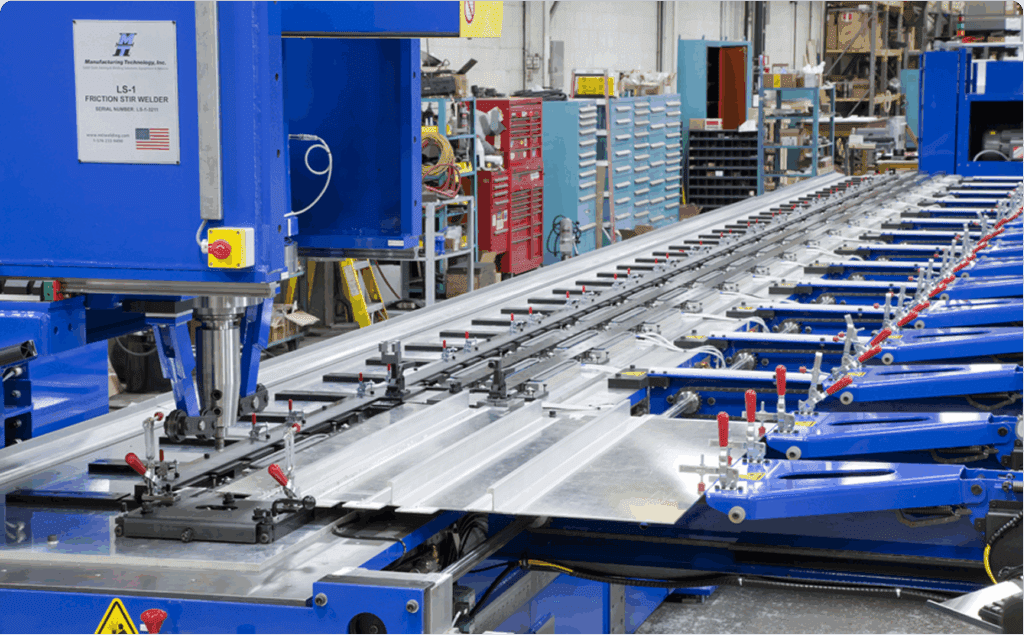

As organizations seek to automate welding in manufacturing, understanding the variables that influence the optimal FSW tool design for specific applications is helpful, including the type of FSW tool. From conventional pin configurations to custom FSW tools, each equipment type is engineered for specific weld profiles, materials, and production goals.

While we provide expert guidance to manufacturers and engineers on designing FSW tools, here is a guide to break down the most widely used types of FSW tools.

Conventional Fixed Pin Tools

Conventional or fixed pin FSW tools represent the foundational design in FSW technology. These tools feature a single shoulder and a pin of constant length that cannot be adjusted during the welding process.

For butt joint configurations, the pin length is typically slightly less than the thickness of the workpiece, while for lap joints, it is slightly longer to ensure adequate penetration. The profile of the pin is a critical design element, with various shapes employed to optimize material flow and weld characteristics:

- Cylindrical Pins: Often used for softer materials like aluminum. A cylindrical pin FSW tool provides effective stirring and a good balance of vertical and horizontal material flow.

- Threaded Cylindrical Pins: The threaded pin FSW tool incorporates threads that aid in the downward movement of material towards the weld root, which improves penetration and root quality.

- Tapered Pins: Reduce transverse forces during welding and improve material flow, particularly beneficial for thicker sections. Some designs of the tapered pin FSW tool incorporate re-entrant features or variable pitch threads to further enhance material movement.

- Fluted Pins: The fluted pin FSW tool is characterized by helical or straight grooves that promote more active disruption and mixing of material within the weld zone.

- Polygonal Pins: This pin has square, triangular, and hexagonal profiles that improve material flow and mixing due to their flat surfaces and sharp corners. Friction welding with a polygonal pin FSW tool often results in enhanced mechanical properties.

Conventional fixed pin tools find extensive use across various industries:

- Aerospace: Welding of aircraft skins, fuselage panels, and fuel tanks

- Automotive: Body panels, wheels, chassis components, EV battery components

- Marine: Fabrication of deck panels and ship hulls

- Rail Transportation: Construction of car bodies and deck panels

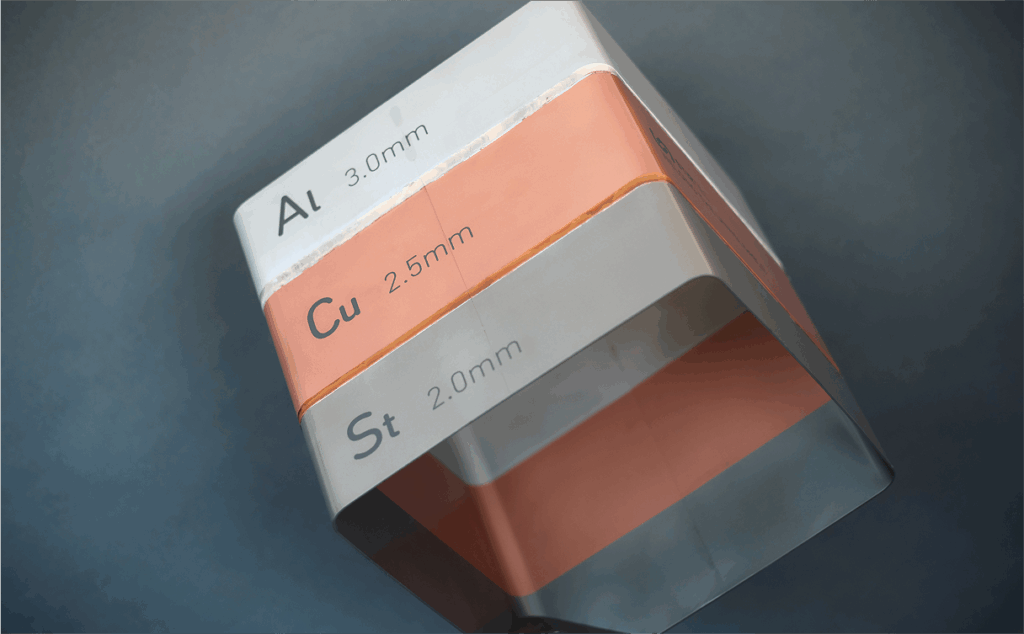

While primarily used for aluminum and magnesium alloys, these tools can also join copper and titanium when constructed from appropriate materials that can withstand the higher temperatures and forces involved.

Advantages:

- Simple, robust design with fewer mechanical complexities

- Cost-effective for many common applications

- Wide range of pin profiles available to suit different materials and joint requirements

Limitations:

- Leave an exit hole at the end of the weld

- May struggle with variable thickness materials

- Limited to planar or gently curved weld paths as the tool must remain normal to any 3D surface contours.

Bobbin (Self-Reacting) Tools

Bobbin tools, also known as self-reacting FSW tools, represent a significant advancement in FSW technology. These tools feature two shoulders positioned on opposite sides of the workpiece, connected by a pin.

The dual-shoulder design fundamentally alters the force dynamics and heat distribution in the weld zone:

- Fixed-Gap Configuration: The distance between the shoulders remains constant during welding, suitable for uniform thickness materials.

- Variable-Gap (Floating) Configuration: Allows adjustment of the distance between shoulders during welding, accommodating variations in workpiece thickness.

Bobbin tools offer several distinct advantages over conventional single-shoulder designs:

- Elimination of Backing Support: No need for an anvil, simplifying tooling and fixturing requirements.

- Balanced Heat Input: More uniform heat distribution through the workpiece thickness, reducing distortion.

- Improved Weld Root Quality: Eliminates root defects common in conventional FSW.

- Reduced Axial Forces: Lower forces on the welding machine and fixtures.

- Enhanced Tolerance to Thickness Variations: Particularly beneficial for materials with dimensional inconsistencies.

The processed area produced by bobbin tools typically has a more rectangular cross-section compared to the triangular shape observed with conventional single-shoulder tools, often resulting in more consistent mechanical properties through the thickness.

These tools are particularly valuable for:

- Welding hollow extrusions where access to the interior is limited

- Joining thick plates

- Fabricating large panels where distortion must be minimized

- Aerospace structures where the absence of root flaws is critical

- Rail vehicle construction

Limitations:

- May require a special entry bore for starting the weld depending on product geometry and the application.

- Depending on product design the exit hole may need to be re-sealed via additional solid state welding methods such as plug welding.

- Traverse Speed is slower than using a traditional weld tool.

- Requires more torque and a beefier tool holder, robust spindle capability

- The welded parts must be thick enough to support the in-plane process loads.

- Machine size appears to be the only limiting factor in welded plate thickness.

Download the FSW Tool Guide

Learn more about the factors that shape FSW tool design—and why one size doesn’t fit all.

Retractable Pin FSW Tools

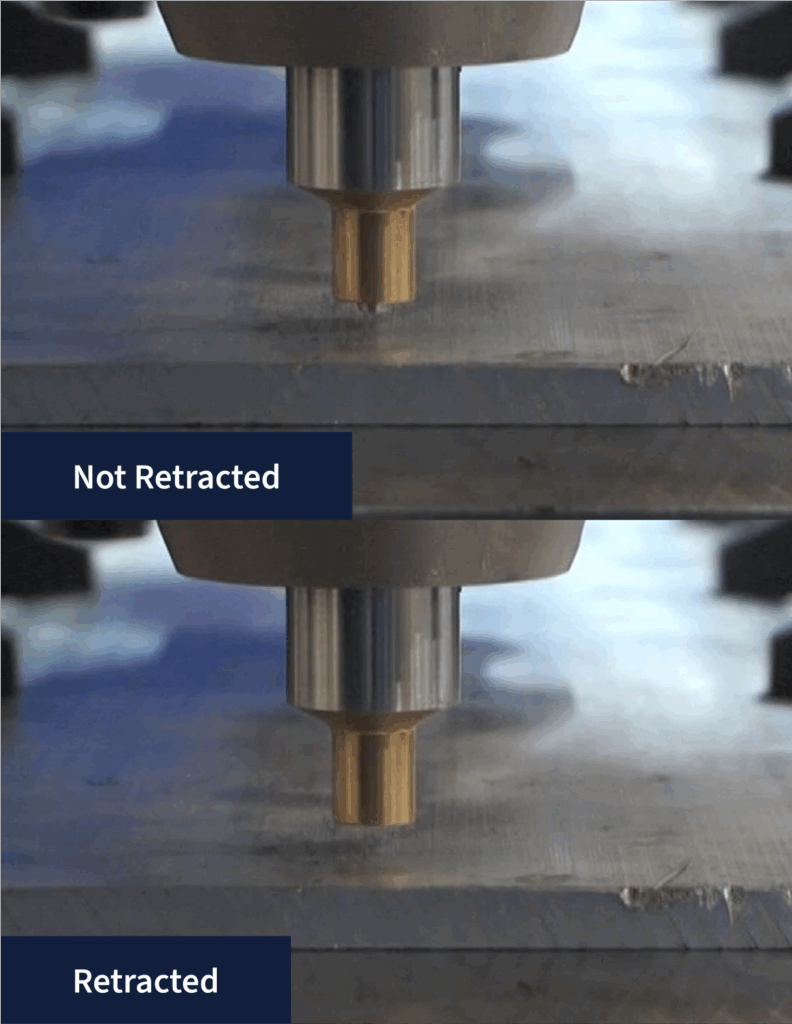

Retractable pin tools incorporate a mechanism that allows the pin to be withdrawn into the tool shoulder during the welding process, addressing one of the primary limitations of conventional FSW tools.

The retraction system typically uses a servo-controlled axis to gradually withdraw the pin as the tool approaches the end of the weld path. This controlled retraction maintains the integrity of the weld while eliminating the exit hole that would otherwise remain.

- Elimination of Exit Holes: Removes the stress concentration point typically left at the end of FSW welds.

- Adaptability to Variable Thicknesses: Pin length can be adjusted in real-time to ensure consistent penetration across workpieces with varying thickness.

- Reduced Post-Processing: Minimizes or eliminates the need for additional operations to close exit holes.

- Enhanced Structural Integrity: Provides complete, continuous welds critical for pressure vessels and sealed containers.

Retractable pin tools have found success in:

- Aerospace Industry: Fabrication of fuel tanks, rocket tanks, cryogenic hydrogen tanks, and other pressure vessels.

- NASA Applications: Welding of docking ports and hatches in space habitat modules.

- Automotive Components: Structures requiring seamless welds for structural integrity or aesthetic purposes.

- Sealed Containers: Any application where leakage through an exit hole would be problematic.

This technology directly addresses a key limitation of conventional fixed pin tools, broadening the applicability of the process in industries with stringent demands for weld integrity and surface finish.

Stationary Shoulder FSW Tools

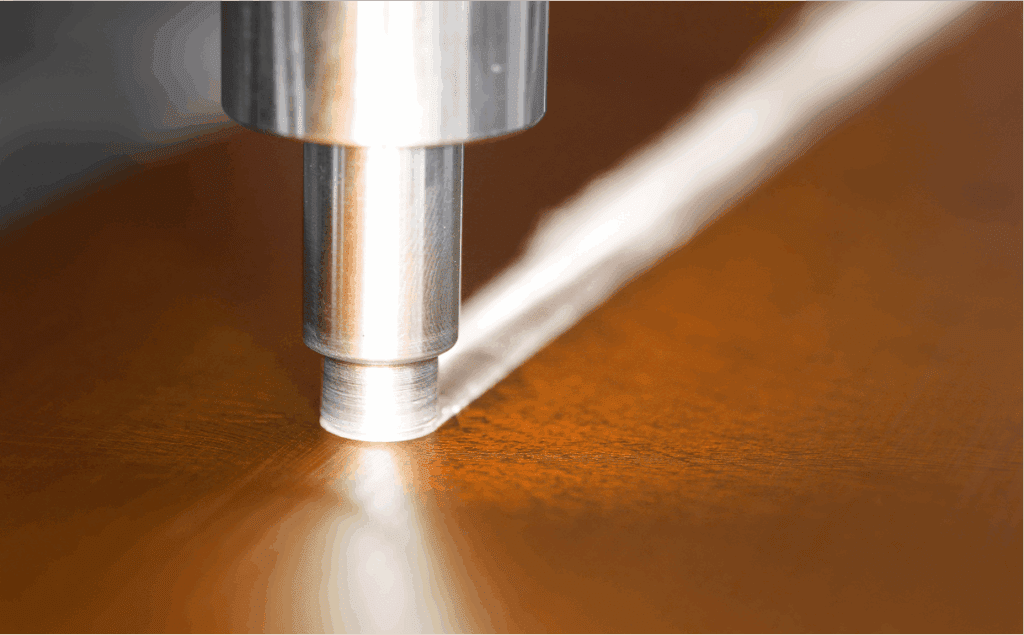

Stationary Shoulder Friction Stir Welding (SSFSW) takes a unique approach to the FSW process. In this variant, the shoulder of the tool remains non-rotating while only the pin rotates while they both traverse along the joint line.

During welding, the stationary shoulder slides against the workpiece surface while the rotating pin generates heat and facilitates material mixing. This separation of functions allows for more precise control of heat input and material flow.

- Reduced Heat Input: Lower temperatures compared to conventional FSW, minimizing thermal distortion.

- Smoother Surface Finish: Reduces the marks typically left by rotating shoulders.

- Reduced Flash Formation: Minimizes excess material expelled from the weld zone.

- Improved Uniformity: More consistent heat distribution through the workpiece thickness.

- Heat concentration sub-surface about the pin leads to defects such as cracking and voids.

- Galling surface roughness when the welded material adheres to the shoulder and lack of penetration.

- Higher cost to manufacture compared to traditional pin tools.

- Higher maintenance cost to change out and confirm tools during production.

- Surface irregularities if not replaced in a timely manner tool wear increases the gap between rotating & non-rotating tool components.

SSFSW has proven effective for welding:

- Aluminum Alloys: Including high strength 2XXX and 7XXX series

- Magnesium Alloys: Offering improved control for these temperature-sensitive materials

- Titanium Alloys: Benefiting from the more uniform heat distribution

- Copper Alloys: Allowing better management of high thermal conductivity

- Steels: Providing improved surface finish and reduced distortion

These capabilities have led to adoption across multiple industries:

- Aerospace: Aircraft wings and fuselage panels

- Automotive: Body panels, engine blocks, and battery boxes

- Rail: Structural components for train cars

- Shipbuilding: Aluminum floors for superstructures

- Energy: Heat exchangers and cryogenic tanks

SSFSW is particularly advantageous for materials with low thermal conductivity, such as titanium, where controlling heat distribution is critical for weld quality.

Friction Stir Spot Welding Tools

Friction Stir Spot Welding (FSSW) is a specialized variant designed specifically for creating individual spot welds, primarily in lap joint configurations.

In FSSW, a rotating tool with a pin and shoulder is pressed onto the top sheet, and the pin is plunged into the joint area between overlapping sheets. The tool stirs the material to form a weld, then is retracted.

Several tool designs have been developed for FSSW:

- Standard One-Piece Tools: The simplest design, though these leave a keyhole upon retraction.

- Refill FSSW Tools: Feature mechanisms to fill the hole left by the pin, resulting in a smoother surface finish.

- Pinless FSSW Tools: Rely solely on shoulder action to create the weld, avoiding the keyhole defect entirely.

FSSW offers several benefits compared to conventional resistance spot welding:

- Higher Joint Strength: Typically produces stronger connections.

- Improved Fatigue Performance: Better long-term durability under cyclic loading.

- Dissimilar Material Joining: Can effectively connect aluminum to steel, aluminum to magnesium, and other challenging combinations.

- Enhanced Electrical Conductivity: Beneficial for electrical applications.

- Cleaner Process: Eliminates material splatter and fume generation.

FSSW has found widespread use in:

- Automotive Industry: Joining body components such as doors, tailgates, and roof panels.

- Lightweight Vehicle Construction: Creating aluminum-steel connections to reduce vehicle weight.

- Electronics Industry: Joining connectors and enclosures.

- Rail Vehicle Manufacturing: Various structural applications.

- Aerospace: Increasingly adopted for aircraft structure assembly.

The development of refill FSSW technology has further expanded applications by improving the surface finish and appearance of spot welds, making the process viable for visible components where aesthetics matter.

Emerging and Specialized FSW Tool Designs

Beyond the primary tool types, ongoing research and development have produced several specialized FSW tools for specific applications and challenges.

Featuring more than one pin, these multi-pin FSW tools are being investigated for:

- Enhanced stirring and material flow

- Improved weld quality in certain materials

- Potential for faster welding speeds

- Better mixing in dissimilar material joints

Developed to address heat management challenges:

- Internal cooling channels for improved temperature control

- Designs promoting better heat dissipation

- Water-cooled tool holders for extended tool life

- Critical for high-temperature applications like steel and titanium welding

Titanium-Specific Tools:

- Prioritize uniform heating throughout material thickness

- Often made from tungsten carbide, tungsten-rhenium alloys, or PCBN

- May incorporate special features to compensate for titanium’s poor thermal conductivity

Steel-Welding Tools:

- Designed for exceptional strength and wear resistance

- Commonly use PCBN or other ceramic materials

- Focus on maintaining tool integrity at the high temperatures involved

Copper-Welding Tools:

- Address copper’s high thermal conductivity

- Typically made from tungsten carbide or similar materials

- Feature designs to maintain adequate heat at the weld interface

These specialized tool developments are crucial for extending FSW capabilities to more challenging materials and applications, overcoming the limitations of conventional tool designs.

Talk with an Expert Today

As FSW technology continues to advance, so do the types of FSW tools available to meet today’s diverse manufacturing demands. With evolving FSW tool configurations, including specialized pin profiles, tool shoulders, and custom geometries, selecting the right solution is essential for efficient material preparation and high-performance welds. Download our guide to discover answers to more frequently asked questions about FSW, or Speak with an expert today.

FSW Tools Explained: What You Need to Know

Get practical, no-nonsense answers about friction stir welding tools.

Get the information you need, before you need it — free and straight to your inbox from industry experts.