Future Trends in FSW Tool Technology

Future of FSW Tools

The future of FSW tools is rapidly advancing, driven by innovations in tool design, smart manufacturing, and the growing demand for automated friction stir welding.

As FSW technology continues to advance, manufacturers and engineers must adapt to the latest FSW tool designs to enhance productivity and reduce costs. Navigating these innovations requires the guidance of experienced engineering experts who can help identify the right solutions to optimize your welding process.

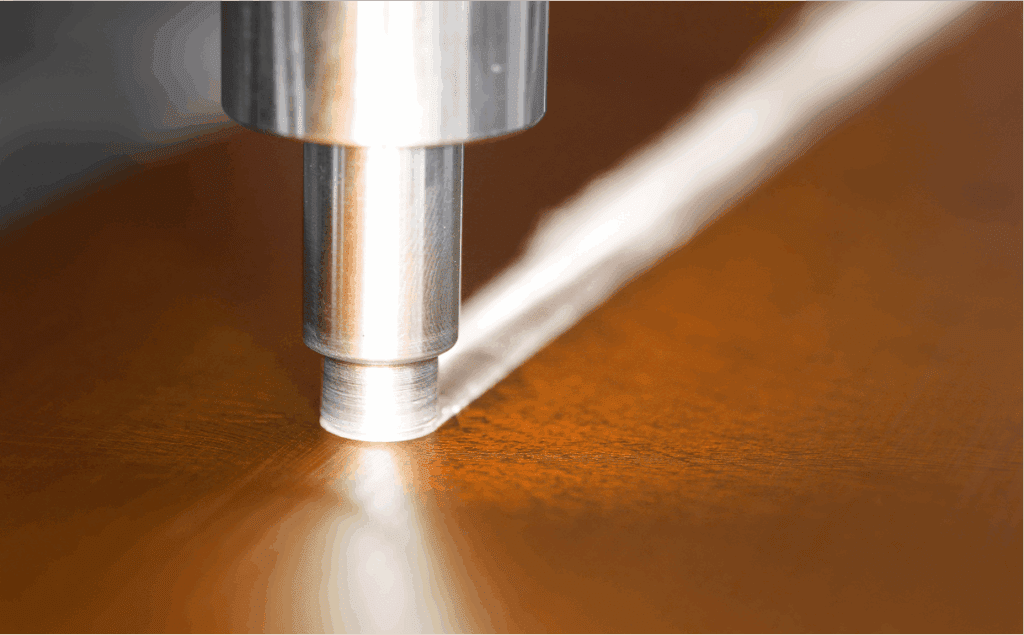

Emerging trends in advanced FSW tool technology—such as intelligent FSW tools, sensor-equipped components, and integrated cooling systems—promise to enhance tool performance, extend lifespan, and improve weld quality across a wide range of applications.

These innovations are at the forefront of the digital transformation in automated welding, paving the way for more precise, data-driven production environments. Below, we explore what we can look forward to in the research and development of FSW tools.

Research Focus Areas on Advanced FSW Tool Technology

Advanced Material Innovations in FSW Tools

Researchers are exploring novel tool materials with enhanced properties:

- Intermetallic alloys with improved high-temperature strength

- Ceramic-metal composites combining wear resistance with toughness

- Carbon-based materials, including diamond and advanced carbides

- Refractory metal alloys with optimized compositions

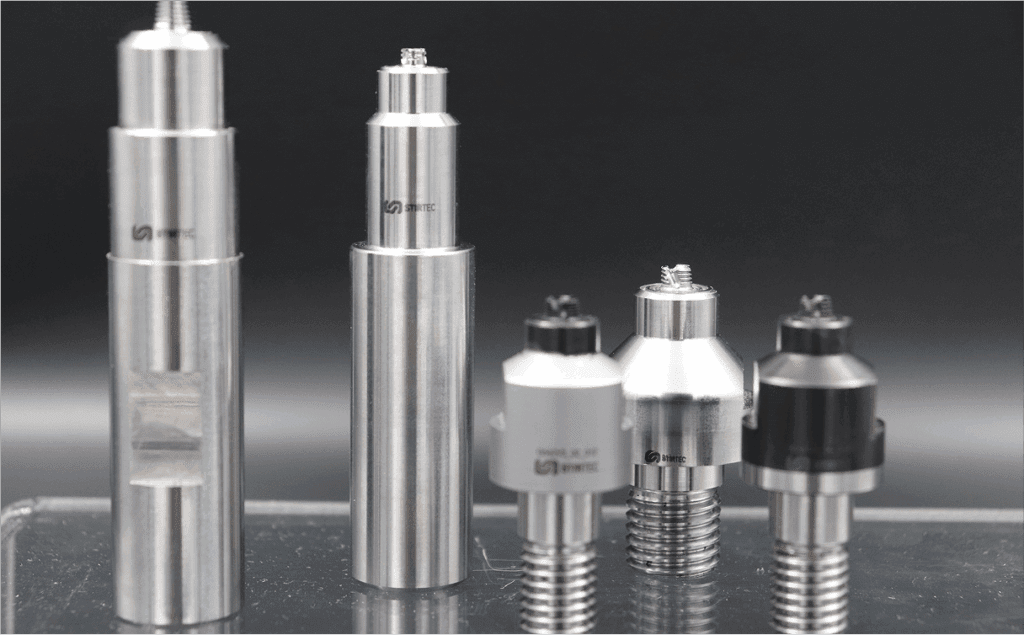

Adaptive and Smart FSW Tools

The integration of sensors and control systems is creating smarter FSW tools:

- Real-time temperature monitoring at the tool-workpiece interface

- Force-sensing capabilities for process optimization

- Adaptive control of pin position based on workpiece variations

- Self-adjusting tool parameters for consistent weld quality

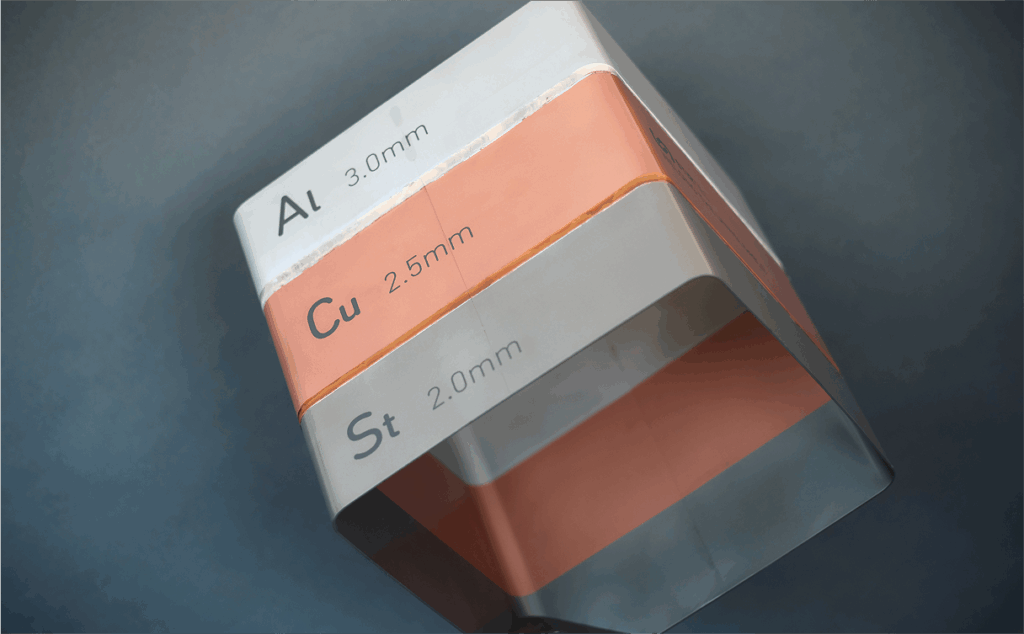

Expanding Material Range for Next- Gen FSW Tools

Tool development is enabling FSW of challenging materials:

- Advanced tools for high-temperature alloys

- Specialized designs for joining dissimilar material combinations

- Tools optimized for polymer and composite welding

- Solutions for joining ultra-thin and ultra-thick sections

Download Our FSW Tool Guide

One size doesn’t fit all FSW tool applications. Learn more about the basic variables that influence the ideal FSW tool tailored to your production requirements.

Emerging Applications

The advancement of FSW tool technology is opening new application possibilities:

- Additive Manufacturing: FSW tools for post-processing or integrating 3D printed components

- Microelectronics: Miniaturized tools for joining small-scale components

- Medical Devices: Tools for biocompatible materials with stringent quality requirements

- Renewable Energy: Specialized tools for efficient production of solar panels and wind turbine components

Contact Us for the Latest Applications on FSW Tool Technology

As FSW tool technology continues to evolve, manufacturers and engineers are gaining access to smarter, more adaptive solutions that address today’s most complex production challenges. From advanced tool materials to intelligent FSW tools, emerging innovations are improving the welding of challenging materials, increasing tool performance, and streamlining automated manufacturing workflows.

Whether you’re facing challenges with tool wear, welding dissimilar alloys, or seeking improved energy efficiency, we are here to help you stay ahead of the curve. Our experts are at the forefront of the future of FSW tools, delivering real-world solutions through proven engineering expertise and global contract welding services.

Don’t miss the FSW advancements your project needs. Download our guide and talk with an expert today to discover the latest in next-gen FSW tool technology.

Your Guide to Friction Stir

Welding Tools

From tool types and materials to selection strategies, find the essential information you need to implement the right FSW tools with confidence.

Get the information you need, before you need it — free and straight to your inbox from industry experts.