Selecting the Right Friction Stir Welding Tool

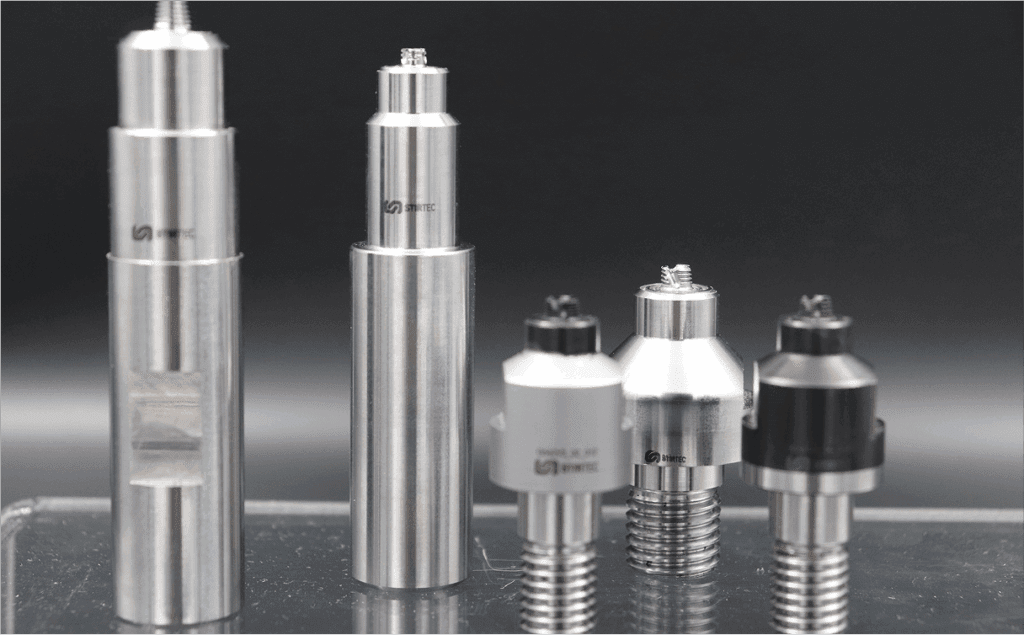

Friction Stir Welding (FSW) Tools

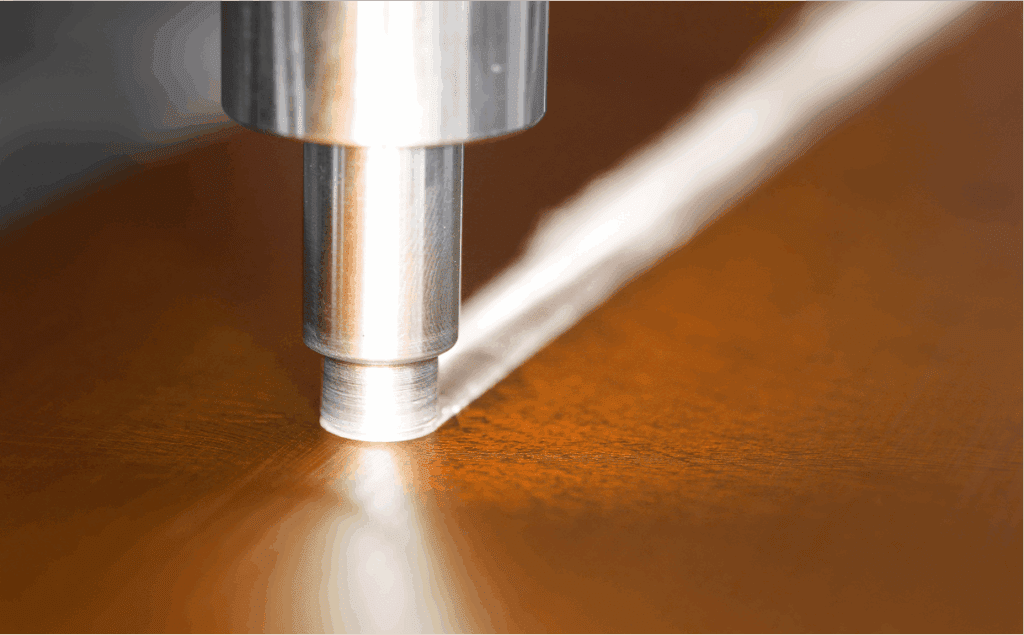

Selecting the right Friction Stir Welding (FSW) tool requires expert insight into key variables that influence FSW tool design.

Understanding these key variables is crucial for achieving strong, consistent, and high-quality welds in your friction stir welding process. From tool material and pin profile to tool geometry, every element impacts weld performance, durability, and efficiency.

Effective FSW tool selection also depends on your joint configuration, quality standards, and the base materials being welded—whether it’s aluminum, steel, copper, magnesium, or dissimilar materials.

Additional considerations may vary by industry, with specialized requirements for aerospace, automotive, shipbuilding, and rail applications. Understanding these variables is essential when choosing FSW tools that meet both technical and production demands.

In this guide, we’ll explore the key factors that influence Friction Stir Welding (FSW) tool design—ranging from material properties and joint configuration to machine capability and production goals. Understanding these variables can help optimize performance and extend tool life. We bring deep application expertise to design a tool that’s tailored to your specific welding needs.

Key Selection Factors for FSW

When designing the FSW tools, several critical factors must be evaluated to ensure optimal weld performance, durability, and process efficiency. The success of your friction stir welding tool depends on choosing components that are compatible with your material type, weld specifications, and industry requirements.

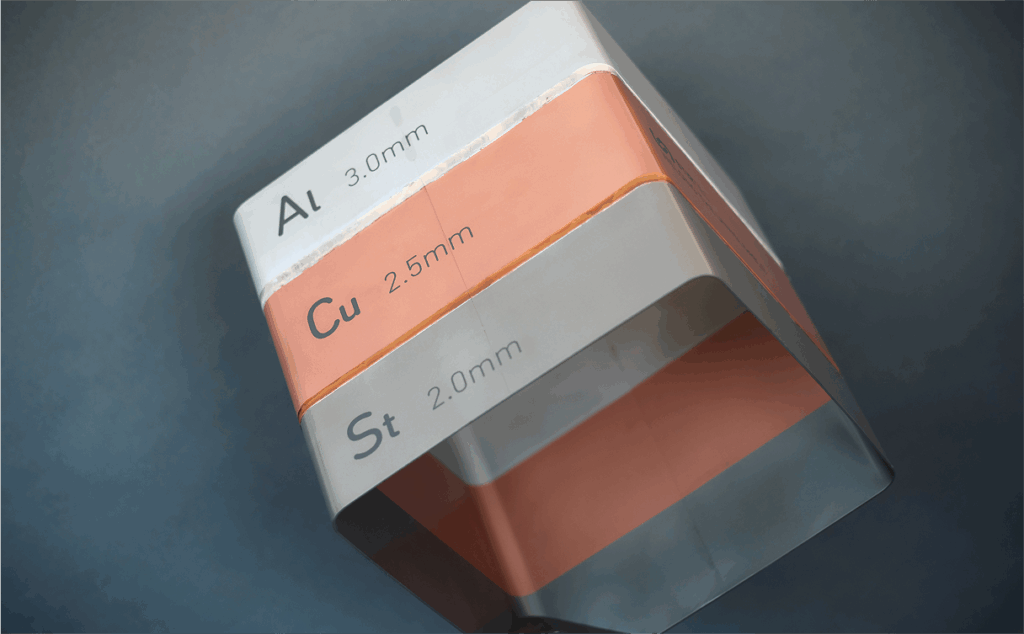

Workpiece Material Type and Thickness

The workpiece material—and its thickness—is one of the most critical considerations when selecting the right FSW tool. While FSW tools for dissimilar materials often rely on standard FSW pins, not all pins are created equal. The success of welding dissimilar metals—such as aluminum to copper or titanium to steel—depends heavily on selecting the right FSW tool material, pin profile, and pin length.

Using a non-consumable pin with the proper material properties ensures the tool can withstand differences in thermal conductivity, melting points, and material hardness. An optimized pin length is also essential for FSW performance in maintaining full weld penetration during the process.

FSW Tool for Various Materials

Each material type presents unique challenges in terms of heat generation, tool wear, and weld quality. Because FSW is often used to join dissimilar metals or materials with varying mechanical properties, your tool pin material must be significantly stronger and more wear-resistant to remain non-consumable throughout the process.

Below are general FSW tool guidelines based on common material categories for optimal FSW efficiency and to minimize FSW tool wear:

- FSW Tool for Aluminum Alloys – For most aluminum alloys, tool steels like H13 are sufficient. For higher strength or more abrasive alloys, consider superalloys or tungsten carbide.

- FSW Tool for Magnesium Alloys – Similar to aluminum, but temperature control is more critical. Tool steels are commonly used.

- FSW Tool for Copper and Copper Alloys – Require tools with excellent heat resistance; tungsten carbide or tungsten heavy alloys are typical choices.

- FSW Tool for Steel – Demands PCBN or advanced ceramic tools due to the high temperatures and forces involved.

- FSW Tool for Titanium – Requires specialized materials like tungsten-rhenium alloys or PCBN that can withstand extreme conditions.

FSW Tool for Thin and Thick Materials

Selecting FSW tools based on material thickness is just as vital as choosing the right tool material. The tool pin length must be compatible with the workpiece thickness to ensure proper weld penetration and structural integrity. A short pin will fail to adequately stir or bond thicker plates, while a long pin used on thin sheets risks damaging the material or causing weld defects.

Below is a general guideline for FSW pin length recommendations based on material thickness ranges.

- FSW Tool for Thin Sheets and Other Materials (< 5mm) Standard fixed pin tools are often sufficient, but the best production rates are always achieved through optimization.

- FSW Tool for Materials of Medium thickness (5-15mm) Requires optimized pin geometries.

- FSW Tool for Thick Plates and Other Materials (> 15mm) Consider bobbin tools or specialized designs.

Acquire the Advantage of Our FSW Tool Guide

Discover the factors that shape the best FSW tool design for your operation.

Desired Weld Properties and Quality Requirements

Organizations across industries—from aerospace to automotive, shipbuilding, and beyond—often have distinct weld properties and quality requirements that influence FSW tool selection. Some applications demand a clean, aesthetic finish with no exit holes, especially for visible or high-specification components. Others prioritize uniform heat distribution to minimize distortion or weld root-defect elimination, critical for structural integrity in pressure-sensitive environments.

Because of these varied requirements, different types of FSW tools have been developed to meet specific application needs.

- High Structural Integrity: Tools designed to minimize defects, possibly with advanced pin profiles.

- Cosmetic Requirements: Stationary shoulder tools provide a more precise heat input and material flow for an improved surface finish.

- Fatigue Performance: Tools that produce fine-grained microstructures.

- Leak-Tight Welds: Retractable pin tools to eliminate exit holes.

Joint Configuration

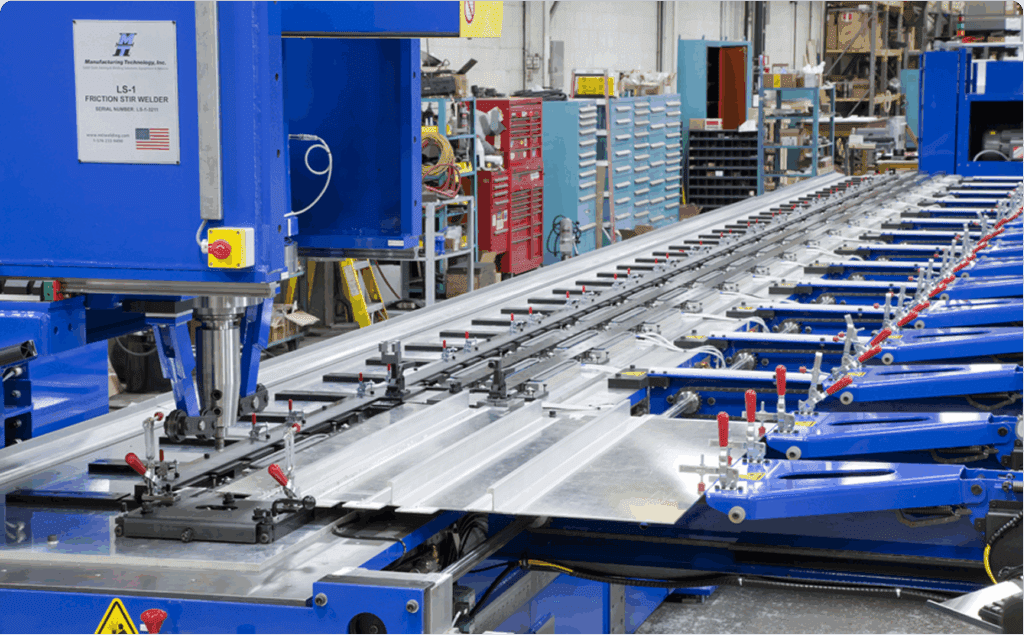

Joint design significantly influences tool selection:

- Butt Joints: Traditional fixed pin tools work well for most applications

- Lap Joints: May require longer pins or specialized geometries

- T-Joints: Often benefit from specialized pin designs

- Spot Welds: Require specific FSSW tools, potentially with refill capability

- Complex 3D Joints: May necessitate convex shoulder tools

Industry-Specific Considerations

Different sectors have unique requirements that influence tool selection:

- Extremely high-quality standards

- Often requires elimination of exit holes (retractable pin tools, or bobbin and plug welding)

- May need tools capable of welding high-strength alloys

- High production rates demand durable tools

- Product cost considerations are often important

- FSSW tools common for joining sheet materials

- Focus on thick plates and long welds

- Tools must be durable for extended operation

- Distortion control critical (bobbin tools advantageous)

- Combination of thick and thin sections

- Often involves aluminum extrusions (bobbin tools beneficial)

- May require specialized tools for complex profiles

Decision Matrix for Common Applications

If you’re seeking the right FSW tool based on common friction stir welding applications, the table below serves as a quick reference guide. It matches tool types to suggested material categories, along with key considerations such as FSW tool cost for each use case.

| Application | Recommended Tool Type | Suggested Material | Key Considerations |

|---|---|---|---|

| Aluminum sheet (< 5mm) | Conventional fixed pin | Tool steel (H13) | Simple, cost-effective |

| Aluminum plate (> 10mm) | Bobbin tool | MP159 or similar | Balanced heat distribution |

| Aircraft fuselage | Retractable pin | Tool steel or superalloy | Elimination of exit holes |

| Steel plates | Conventional with specialized pin | PCBN or Advanced Ceramic | High temperature resistance |

| Automotive spot welds | FSSW tool (possibly refill) | Tool steel | Production speed, appearance |

| Titanium components | Conventional with cooling | W-Re alloy or PCBN | Controlled heat input |

| Copper heat exchangers | Conventional with cooling | Tungsten carbide | Heat management critical |

| Hollow aluminum extrusions | Bobbin tool | Tool steel or superalloy | No backing bar needed |

Reach Out to the Experts to Select the Right FSW Tool

To fully optimize FSW tool performance and efficiency, it’s essential to choose the right equipment for your specific application. Factors such as workpiece material, tool geometry, industry compliance, and process requirements all play a role in effective FSW tool selection.

While this guide offers a structured approach to evaluating options, nothing replaces expert insight when making high-stakes tooling decisions. When you’re planning to design a custom FSW tool tailored to your process, contacting experienced professionals can make all the difference.

Our contract manufacturing services offer end-to-end support—from initial consultation and tool design to production optimization. Let our team help you identify or engineer the right solution to meet your friction stir welding goals.

Download our guide and reach out to an expert today to take the next step toward welding with confidence.

Master the Fundamentals of FSW Tool Selection

Explore commonly asked questions around FSW tool implementation, material compatibility, and how to choose the right tools for your production.

Get the information you need, before you need it — free and straight to your inbox from industry experts.