Friction Stir Welding Tools: Types, Applications & Selection Guide

Friction Stir Welding (FSW)

Friction Stir Welding (FSW) has revolutionized the joining of metals since its invention at The Welding Institute (TWI) in the early 1990s. Unlike conventional fusion welding processes, the FSW process operates as a solid-state joining method, where materials are welded without reaching their melting point or drastically changing material characteristics at the weld interface.

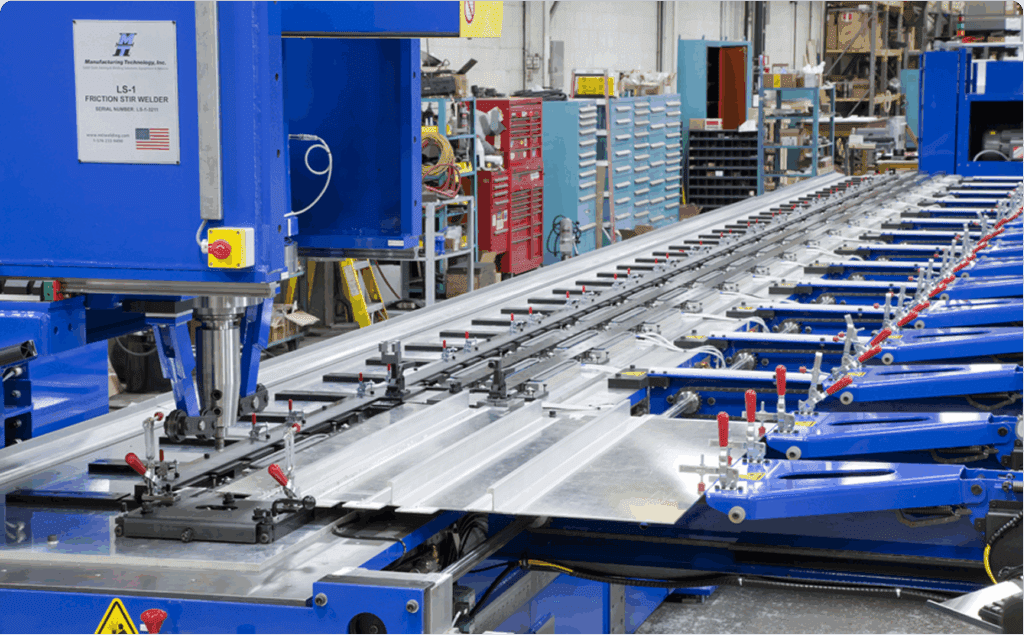

The resulting joint is a high-quality, defect-free weld with minimal distortion, shrinkage, and residual stress, providing one of the strongest welds available. At the heart of this innovative technology lies the FSW tool—a critical component that determines the quality, efficiency, and applicability of the welding process. The pin tools can be precisely engineered to meet the specific requirements of each application, ensuring optimal weld performance.

This comprehensive guide explores the diverse array of FSW tools available today, from conventional single fixed pin designs to advanced dual shoulder self-reacting systems. Whether you’re an engineer looking to learn more about FSW tooling, a researcher investigating novel welding techniques, or a manufacturing professional looking to optimize your joining processes, understanding the characteristics and applications of different FSW tools is essential for achieving optimal results, especially with expert guidance.

Learn More About The Tools Behind Friction Stir Welding

Get straightforward answers to the most commonly asked questions about FSW tool implementation—from understanding tool materials and types to gaining insights on future trends in FSW tool technology.

Friction Stir Welding Basics: What It Is, Its Benefits, and More

Friction Stir Welding is a solid-state joining process that employs a non-consumable rotating tool to generate localized heat and mechanical intermixing between the faying surfaces of two workpieces. Unlike traditional welding methods that melt the base materials, FSW creates welds at temperatures below the melting point, resulting in several significant advantages.

Friction Stir Welding Advantages Over Traditional Welding

- Enhanced mechanical properties in the weld zone

- Minimal distortion of the welded components

- Absence of typical melt-related defects like porosity and solidification cracking

- Capability to join dissimilar materials that challenge conventional welding techniques

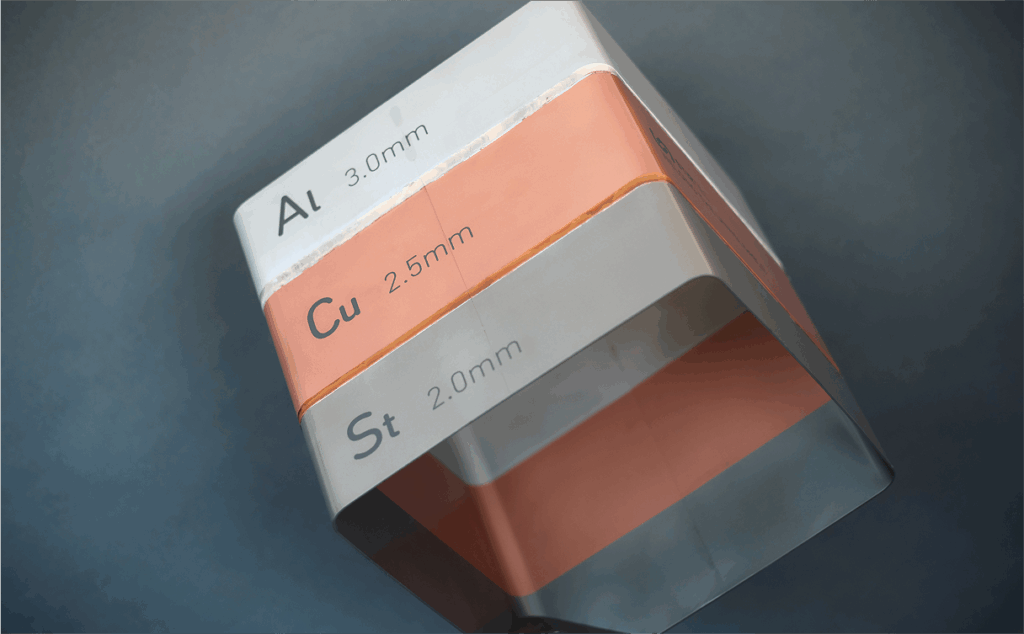

Aside from these FSW benefits, the welding method has proven particularly effective for materials that are difficult to weld using fusion methods, including high-strength aluminum alloys in the 2XXX and 7XXX series, as well as magnesium, copper, titanium, certain grades of steel, and even polymers. This versatility has led to widespread adoption across many industries, including aerospace, automotive, marine, and rail transportation.

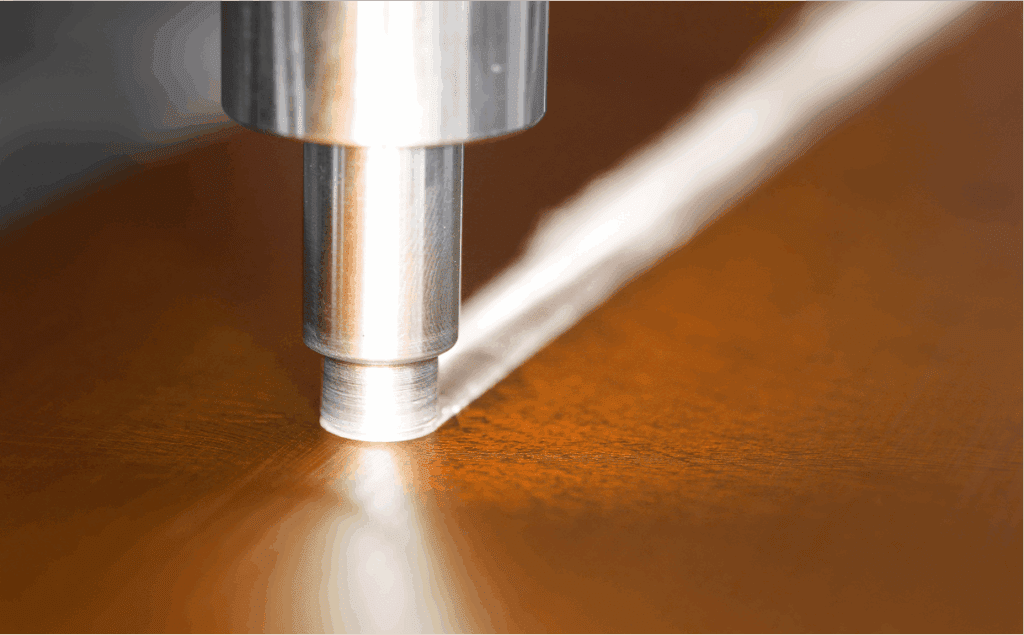

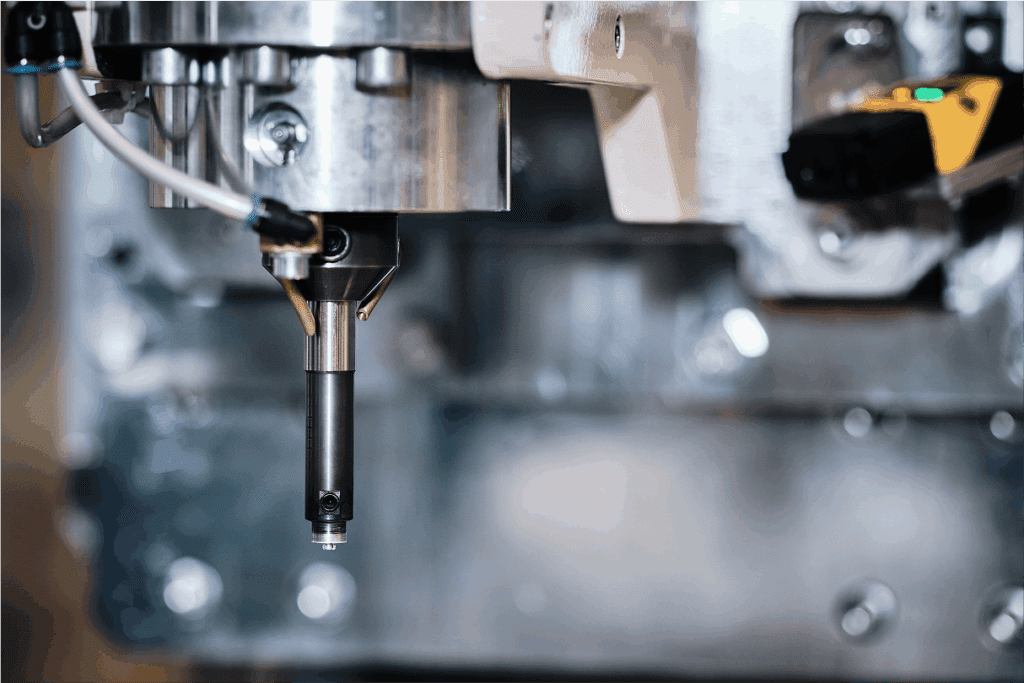

The friction stir welding process works through the combined action of frictional heating and mechanical stirring. As the tool rotates and traverses along the joint line, it generates heat through friction with the workpiece, softening (but not melting) the material. The tool then mechanically mixes the materials from both sides of the joint, creating a solid-state bond with refined grain structure and superior mechanical properties.

FSW Tool Fundamentals

Basic FSW Tool Parts and Their Functions

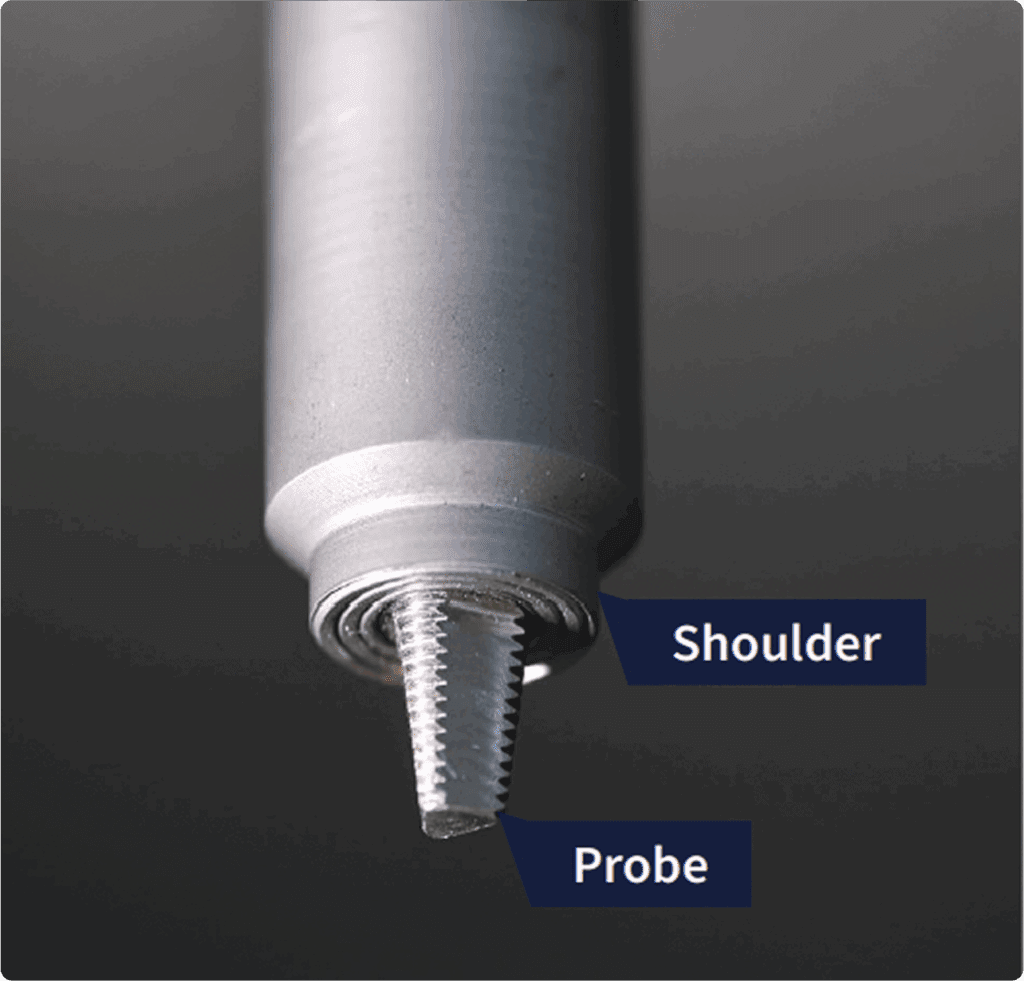

The fundamental design of an FSW tool centers around two primary components:

This larger diameter component contacts the surface of the workpiece and serves multiple critical functions:

- Generates most of the frictional heat necessary for welding

- Exerts downward pressure to contain the softened material

- Prevents material expulsion from the weld zone

- Contributes to the forging action required for a robust weld

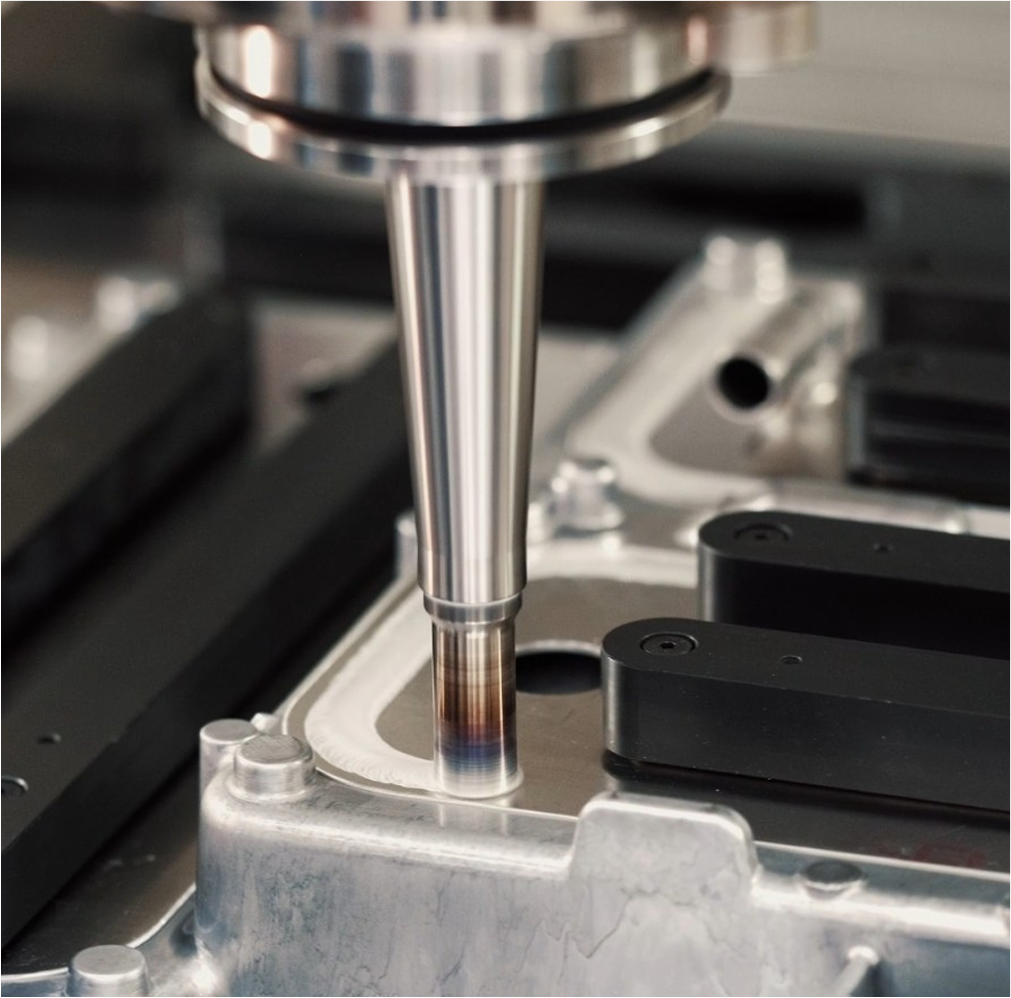

This smaller diameter component extends from the shoulder and inserts into the joint line between workpieces. Its key functions include:

- Stirring and mechanically intermixing the softened material

- Creating material flow patterns that facilitate bonding

- Distributing heat throughout the workpiece thickness

The effectiveness of heat generation and the efficiency of material mixing are crucial for achieving a structurally sound and high-quality weld. Tool design is therefore focused on optimizing these aspects based on the specific materials being joined and the desired properties of the weld.

How Tool Design Affects Weld Quality

The geometry and features of both the shoulder and pin significantly influence:

The surface area and features of the tool determine the amount of frictional heat produced during welding.

The pin profile dictates how material moves around the tool, affecting the homogeneity of the weld.

Different tool designs produce varying microstructures in the weld, impacting mechanical properties.

Proper tool design can minimize common FSW defects such as voids, tunnels, and incomplete penetration.

How quickly and efficiently the pin tool can follow the weld path profile to perform the weld, effectively minimizing process cycle time.

Engineers continually refine FSW tool designs to enhance performance across these parameters, leading to the development of specialized tools for specific applications and materials.

Download the FSW Tool Guide

Learn more about the factors that shape FSW tool design—and why one size doesn’t fit all.

Types, Applications, and Selection Guide for Friction Stir Welding

As FSW continues to transform solid-state joining, the tools behind this technology are advancing in material composition, geometry, and performance. With this evolution comes a need for a clear understanding of the types of FSW tools, their applications—along with a trusted partner who has the knowledge and experience to design the right pin tool tailored to your specific manufacturing and engineering needs.

This guide outlines the fundamentals of FSW tool design, explains the friction stir welding applications, and provides expert insight into key variables that influence FSW tool design for improved efficiency, durability, and weld quality.

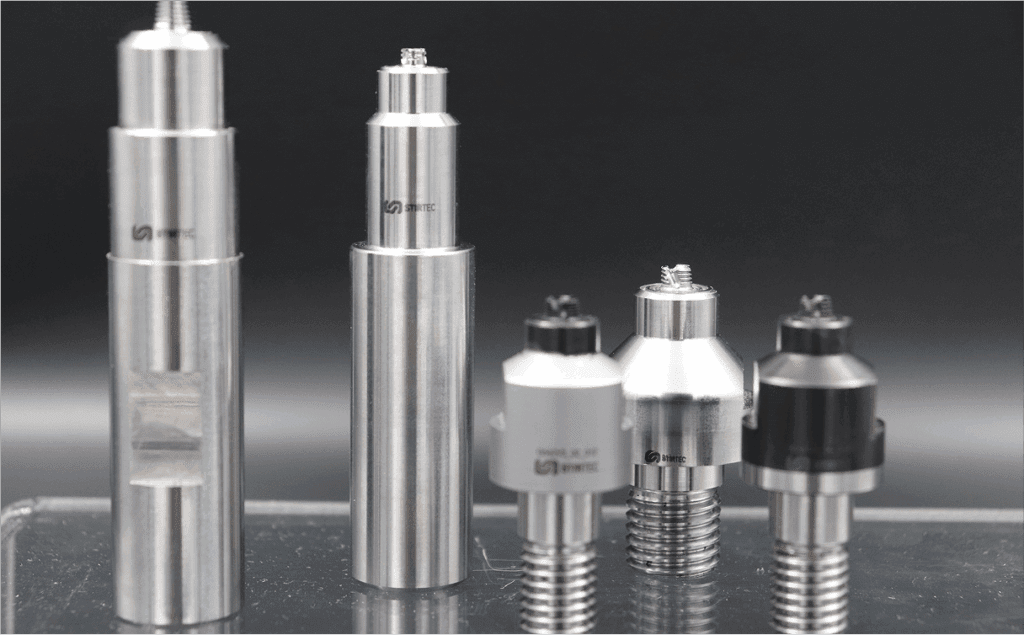

Types of Friction Stir Welding Tools

FSW tools are categorized by their tool pin profiles, shoulder designs, and intended welding applications. Tool types vary based on the materials being joined, joint configuration, and weld parameters. The right design can significantly reduce material prep, lower post-weld machining, and help achieve defect-free welds—all while eliminating common issues found in fusion welding.

FSW Tool Materials

The materials used for FSW tool components must endure extreme mechanical stress, wear, and thermal loads. Common choices include tool steels, tungsten-based alloys, and ceramic composites—each selected based on the metal or alloy being joined. Discover the benefits of different FSW tool materials.

The Right FSW Tool Starts with the Right Design

A structured FSW tool design process ensures compatibility with your project’s materials, reduces the risk of weld defects, and enhances production quality. We provide expert guidance in selecting, designing, and implementing the ideal tool for your operational objectives.

Future Trends in FSW Tool Technology

With advancements in FSW tool geometry, probe design, and automated FSW machines, the future of friction stir welding tools continues to grow. Discover the promising directions research and development have produced.

Talk with an FSW

Implementation Expert

Friction Stir Welding fundamentals involve the solid-state joining of two materials together using a rotating pin, creating welds with enhanced mechanical properties, minimal distortion, and absence of melt-related defects.

FSW tools have evolved significantly since the process was first developed, diversifying into numerous specialized designs to address specific materials, joint configurations, and quality requirements. From the fundamental fixed pin tools to advanced designs like self-reacting retractable pin systems or dual shoulder self-reacting systems, each type offers unique advantages and is optimized for particular applications.

The selection of the appropriate FSW tool involves careful consideration of multiple factors, including workpiece material, thickness, joint design, and industry requirements. This decision significantly impacts the resulting weld quality, production efficiency, and tool lifespan.

As industries increasingly adopt FSW technology for its numerous benefits over conventional welding methods, it continues to mature. Ongoing research into tool materials, geometries, and integrated functionalities promises to further expand the FSW applications and capabilities across manufacturing sectors.

For engineers and manufacturers considering FSW implementation, understanding the diverse landscape of available tools is essential for optimizing processes and achieving high-quality, cost-effective welds that meet specific application requirements.

Reach Out to an Expert

for Your Project!

Frequently Asked Questions

Conventional fixed pin tools made from tool steel (typically AISI H13) are the most common for welding aluminum alloys. These tools offer a good balance of performance and cost-effectiveness for many standard applications. For higher strength aluminum alloys or applications requiring extended tool life, superalloys or tungsten carbide tools may be preferred.

Yes, FSW tools can successfully join dissimilar materials, though this often requires specialized tool designs. The key challenges include different flow stresses, melting points, and thermal conductivities between the materials. Tools for dissimilar welding may feature asymmetric designs, offset positioning, or specific pin profiles optimized for the material combination. Common dissimilar joints include aluminum-magnesium, aluminum-steel, and aluminum-copper.

Tool life varies significantly depending on the design of the tool for the task, tool material, workpiece material, and process parameters:

- Tools for aluminum: A high-quality tool steel design may last for hundreds or even thousands of meters of weld.

- Tools for steel or titanium: PCBN tools might achieve tens or hundreds of meters before requiring replacement.

- Tools for abrasive materials: May have shorter lifespans due to accelerated wear.

Regular inspection and timely replacement of worn tools are essential for maintaining weld quality.

FSW tool wear occurs primarily through:

- Improper tool design for task or material.

- Abrasion from hard particles in the workpiece material

- High temperatures causing softening or degradation of the tool material

- Chemical interactions between the tool and workpiece

- Mechanical stresses leading to fatigue or fracture

Minimization strategies include:

- Designing the tool to the task and specific joint /application

- Selecting appropriate tool materials for the application

- Optimizing process parameters to reduce thermal and mechanical loads

- Using cooling systems for high-temperature applications

- Applying wear-resistant coatings to tool surfaces

- Regular tool maintenance and reconditioning

Cost analysis for FSW tools should consider:

- Initial tool cost: Ranges from relatively inexpensive tool steel designs to costly PCBN tools

- Tool life expectancy: More expensive tools may offer longer service life, offsetting initial cost

- Production volume: Higher volumes justify more expensive, longer-lasting tools

- Changeover time: Complex tools may require more time for replacement

- Quality requirements: Higher quality demands may necessitate premium tools

For high-volume production, the total cost per weld is often more important than initial tool cost. For lower volumes or prototype work, simpler and more economical tools may be sufficient.

Get the information you need, before you need it — free and straight to your inbox from industry experts.