Selecting the right subcontractor is vital for your project’s success. It helps avoid project failures, additional costs, re-work, and negative company reputation.

Friction welding benefits industries with high quality and safety standards, like aerospace, automotive, and industrial sectors. It removes human error in part production. Its process is twice or up to a hundred times faster than traditional fusion welding. Its ability to join dissimilar metals and diverse geometries also opens bigger possibilities in custom part design.

With all these benefits, friction welding services are on the rise. Project managers must assess which friction welding contractors can give them the best advantage in project timelines, costs, and final product quality.

Checklist for Selecting a Subcontractor for Friction Welding Services

Here is a checklist project managers can follow when choosing a friction welding contractor.

Expertise

Is friction welding their primary or secondary service?

What friction welding technologies do they have available?

What is their experience with varying material grades, gauges, applications, and sizes?

Are they experienced in navigating various customer First Article Inspection (FAI), Production Part Approval Processes (PPAPs), and other industry-specific audits or developing customer-specific quality systems?

Certification

Does the subcontractor hold relevant industry certifications, such as ISO 9001:2015, NADCAP, or other applicable accreditations?

Quality Assurance

Do the subcontractors comprehensively understand how to apply heat treatments correctly on your materials and metal combinations?

Do they have a precise control plan and lockout procedure to minimize the risk of human error?

Do they have a metallurgical lab to conduct weld testing?

What are their protocols for machine and facility maintenance?

Reporting

Does the subcontractor have the capability to procure all materials with material certifications and heat lots included?

What order fulfillment rate does the subcontractor’s quality system show?

Can the subcontractor hold inventory for you?

Can you easily access incident reports and documents?

What is the response time of the subcontractor in times of an incident or problem?

Company Criteria

What is the number of their employees?

Do they have experience in industries similar to your project?

With the checklist above, you can cover essential considerations like technical capabilities and safety protocols in your research and interview of subcontractors. Below, we cover how we came up with this checklist through the five aspects to consider when choosing a friction welding subcontractor.

5 Aspects to Consider When Selecting a Friction Welding Subcontractor

It’s essential to have a structured evaluation process to assess subcontractors for friction welding services. In this article, we have created a framework to help project managers choose a welding vendor that meets all their requirements. This framework focuses on five key areas: expertise, certification, quality assurance, reporting, and company criteria.

By evaluating friction welding subcontractors in these areas, you can mitigate the risks associated with production delays, quality issues, and cost overruns.

1. Expertise in Friction Welding and Welding Services

Experience and specialization reflect a subcontractor’s ability to handle complex projects. A seasoned subcontractor within friction welding is better equipped to handle complex materials and intricate geometries. Here are some important questions to ask when assessing a welding vendor’s capabilities:

Is friction welding their primary or secondary service?

A subcontractor with friction welding as their primary service will possess deeper knowledge and more refined skills than one who offers it as a secondary service.

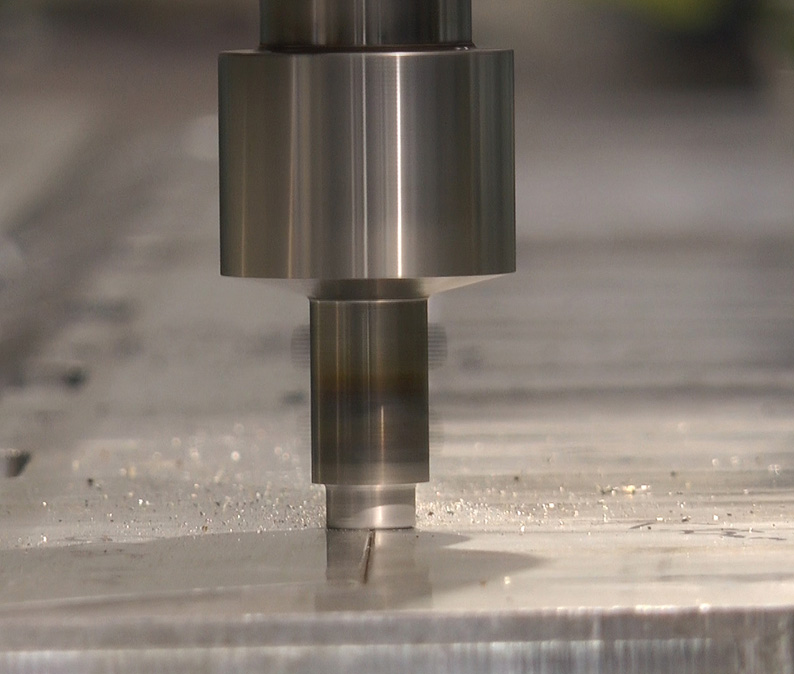

What friction welding technologies do they have available?

A subcontractor with access to various friction welding machines—such as rotary, linear, friction stir, and low force machines—can accommodate a wide array of part sizes, geometries, and material combinations. This flexibility ensures your project is handled with the optimal technology.

What is their experience with varying material grades, gauges, applications, and sizes?

Subcontractors with extensive experience in working with a broad range of materials, grades, and applications—such as aluminum, steel, and bimetallic combinations—can offer more versatile solutions and ensure the most efficient approach to your project.

Are they experienced in navigating various customer First Article Inspection (FAI), Production Part Approval Processes (PPAPs), and other industry-specific audits or developing customer-specific quality systems?

First Article Inspection is a process for verifying new or modified processes for manufacturing parts that meet technical or engineering specifications. Production Part Approval Processes (PPAPs) are vital to robust quality control processes. It is a standardized way of communicating designs and production techniques for manufacturing projects in the aerospace or automotive industry. These processes are only some of the quality systems implemented for customer satisfaction.

As a global leader in friction welding technology since 1976, MTI offers our clients a diverse array of in-house friction welding machines. We also customize friction welding machines for your needs and design prototypes.

2. Certifications and Safety Standards for Subcontract Welding

It is best to choose welding vendors that are certified to work on aerospace projects, as this indicates that they have already passed rigorous reporting, inspections, reviews, and documentation.

Even if your project doesn’t require high technological standards, welding vendors with ISO 9001:2015/AS9100 or NADCAP accreditation will treat your project with the same standards as a plane or rocket.

Does the subcontractor hold relevant industry certifications, such as ISO 9001:2015, NADCAP, or other applicable accreditations?

ISO 9001:2015 is a globally recognized standard for quality management in meeting customer satisfaction and regulatory requirements. Its framework ensures processes are efficient and produce consistent quality.

AS9100 is the international standard for quality management in the aerospace, space, and defense sectors. ISO 9001 is its foundation, establishing standards for manufacturing and service industries.

MTI conforms to the ISO 9001:2015 and AS9100 standards for friction welding machines and associated products and services worldwide.

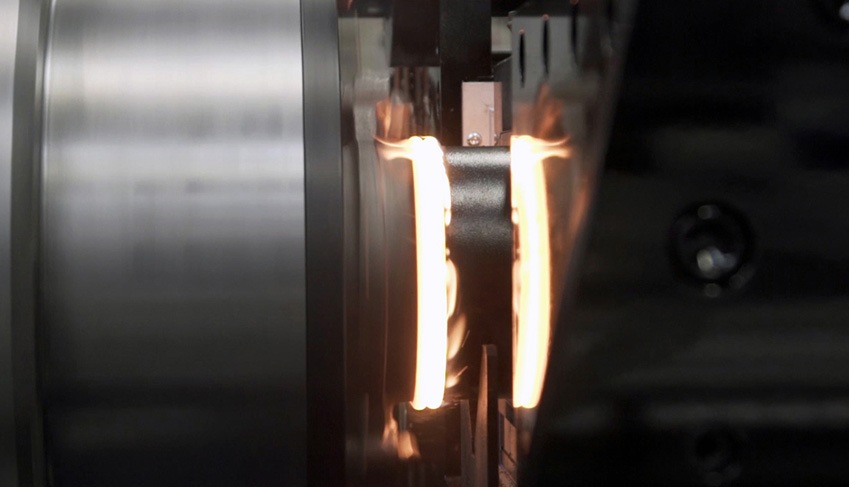

3. Quality Assurance in Friction Welding and Metal Components

Quality control is crucial throughout the friction welding process. While friction welding is machine-controlled and eliminates human errors and possible defects, it is important to know subcontractors’ measures on quality assurance for your projects. Welding quality control must cover welding, post-weld evaluation, and machine and facility maintenance. The questions below cover these factors.

Do the subcontractors comprehensively understand how to apply heat treatments correctly on your materials and metal combinations?

Subcontractors must understand the proper pre- and post-welding treatments for the metallic combinations and materials you are working with. If the weld zone of your parts is not adequately treated with pre-heating, stress relieving, and other processes, it can fail to meet the hardness requirements you need for your project.

Do they have a precise control plan and lockout procedure to minimize the risk of human error?

When interviewing a subcontractor, project managers must know the system in place to prevent non-compliant parts from entering the assembly line. What lockouts in their machines detect a material or procedural fault during weld cycles?

Do they have a metallurgical lab to conduct weld testing?

An in-house metallurgical lab determines the quality of welds through metallurgical testing. A manufacturer can ensure a joint meets the performance requirements fit for welded assembly, such as the heat-affected zone (HAZ) width, HAZ hardness, yield strength, and more.

What are their protocols for machine and facility maintenance?

When machines and facilities are improperly maintained, friction welding subcontractors would have difficulty meeting quality compliance. By asking about their maintenance protocols for machines and facilities, project managers comprehensively check all quality standards of subcontractors.

At MTI, we have built and designed over 800 machines and 350 patents with consistent quality results. Our integrated approach to projects ensures error-free, precision-quality welds.

4. Reporting and Trackability in Your Subcontract Welding Projects

Subcontractors ensure clear communications and transparency with real-time data, progress reports, and traceability in their welding processes. The documentations ensure that your projects stay on schedule and within budget. Furthermore, they provide clarity on unexpected incidents to prevent recurrence.

Does the subcontractor have the capability to procure all materials with material certifications and heat lots included?

Subcontractors who monitor material data throughout the production process indicate a well-managed system, knowledge of material procurement, and financial stability.

What order fulfillment rate does the subcontractor’s quality system show?

Like in any profession, people cannot manage what they don’t measure. Subcontractors who monitor order fulfillment rates can use the information to optimize zero-defect shipments within your timeline.

Can the subcontractor hold inventory for you?

While sending the full part of the production to you is beneficial, it also adds to your workload of managing storage solutions. A subcontractor that can produce and ship parts in batches per your demand lightens the work on your end.

Can you easily access incident reports and documents?

When unexpected events occur, it is vital to determine the cause of failure. To trace the steps backward, you must have access to reports covering the subcontractor’s welding process.

At MTI, we work with various suppliers to secure material procurement for ideal materials and alloys. We also provide streamlined logistics to support your inventory, supply chain management, and production.

5. Company Criteria for Selecting a Subcontractor in Welding Services

Company size, previous projects, and industry specialization reflect a welding vendor’s capabilities to handle your projects.

What is the number of their employees?

The number of skilled professionals a welding vendor has available can indicate their ability to scale operations and efficiently meet your project’s demands.

Do they have experience in industries similar to your project?

Subcontractors with experience in your specific industry—whether aerospace, automotive, medical, or industrial—can offer more applicable solutions and ensure that your project adheres to industry standards and requirements.

Our friction welding teams in the UK, US, and India are uniquely equipped to handle diverse projects in aerospace, defense, oil, mining, and other industries. From concept to completion, we have in-house machines and services to build the machine that makes the part, produce the part, or improve your part for you.

MTI Friction Welding Services – Contact Us Today for Quality Solutions

Selecting the right subcontractor is crucial to the success of your project. By evaluating welding vendors based on the five key aspects, you can identify friction welding services that fit your project’s needs and goals.

MTI is a privately owned, fourth-generation company with decades of expertise, specializing in custom-engineered friction welding services. Since 1976, we have been a leader in solid-state joining solutions, offering advanced technologies and precision across industries.

We provide comprehensive services to cover all aspects of the welding process—pre-weld, welding, and post-weld. From custom prototype design to warranty and ongoing service, we ensure seamless project execution on a global scale.

Contact us today to learn more about how MTI’s friction welding services can support your project needs

Getting Started

MTI is ready to take on your toughest welding challenges. Have a few questions? Let our team of experts take it from here.

LinkedIn: Click here to view our LinkedIn page.