Where Reliability Meets Excellence

Quality At Our Core

At MTI, quality is built into every part and process we deliver. Our operations are backed by a robust quality management system certified to ISO 9001 and AS9100 as well as NADCAP for Welding, ensuring consistent performance across projects and industries.

We also meet a range of AWS, ISO, and MIL-Spec standards to support the most demanding aerospace, defense, and energy applications. MTI is DDTC Registered to support ITAR compliant programs.

For our automotive customers, MTI follows the PPAP (Production Part Approval Process) framework to validate and maintain production quality from prototype to full-scale manufacturing.

Below is a representative list of the certifications, standards, and processes that guide our work:

- AMS6414K

- AMS2750H

- AMS2774E

- AMS5663N

- AMS5664F

- AMS5666G

- AMSQQA200_8

- AS9003

- AS9100D

- AS9102B

- ASTM E1417-E1417M-16

- ASTM E1742-E1742M

- ASTM E23

- ASTM E384-11

- ASTM E3-95

- ASTM E8

- ASTM G131

- AWS B1.10

- AWS B4.0

- AWS C6.1

- AWS C62-C62M

- AWS D1

- AWS 17.1

- AWS D17.3

- BS EN ISO 15620

- BS EN ISO IEC 17011

- CFR-2012

- DD2345

- DIN EN ISO 15085

- E384

- ISO 10012

- ISO 15620

- ISO IEC 17025

- ISO 25239-2

- ISO 4063

- ISO 9001

- MIL-C-15074E

- MIL-DTL-71055B

- MIL-PRF-121

- MIL-PRF-16173

- MIL-PRF-680C

- MIL-STD-1252

- MIL-STD-2035A

- MIL-STD-973

- NADCAP for Welding

- NAS412-1405984-24

- NAVSEA-T9074-AS-GIB-010-271

- PPAP (Production Part Approval Process)

We also meet customer-specific specifications, tailoring our processes to satisfy the exacting requirements of each customer.

Our Commitment

Quality is at the core of our ingenuity

Each weld made within our Contract Friction Welding group is done with the highest possible degree of safety and quality. MTI is equipped to produce parts for the most sensitive environments.

Check Your Material Combination & Geometry

Can Your Application Be Friction Welded?

Compatible Welds

|

Not Seeing Your Combination Of Materials?

That doesn’t mean it can’t be done. Many of our material combinations are also proprietary. That’s why several of our customers use MTI’s in-house metallurgy lab, which will test your materials for strength and durability to see if friction welding is the right process for you.

Please note Weld strength is dependent on materials & geometry.

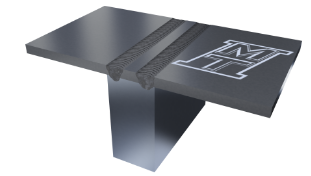

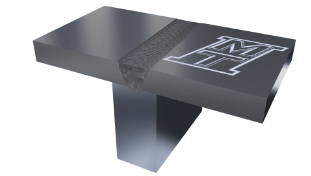

Joint Geometries

Friction Welding can join a wide range of part geometries

Let’s talk about the specifics of your project: