Rotary Friction Welding Machines from MTI

MTI specialises in Rotary Friction Welding machines in all forms – Direct Drive, Inertia, and Hybrid. Rotary Friction Welding can accommodate various part geometries, being well-suited for applications across several industries. We have manufactured and delivered bespoke Rotary machines throughout Europe and the United Kingdom.

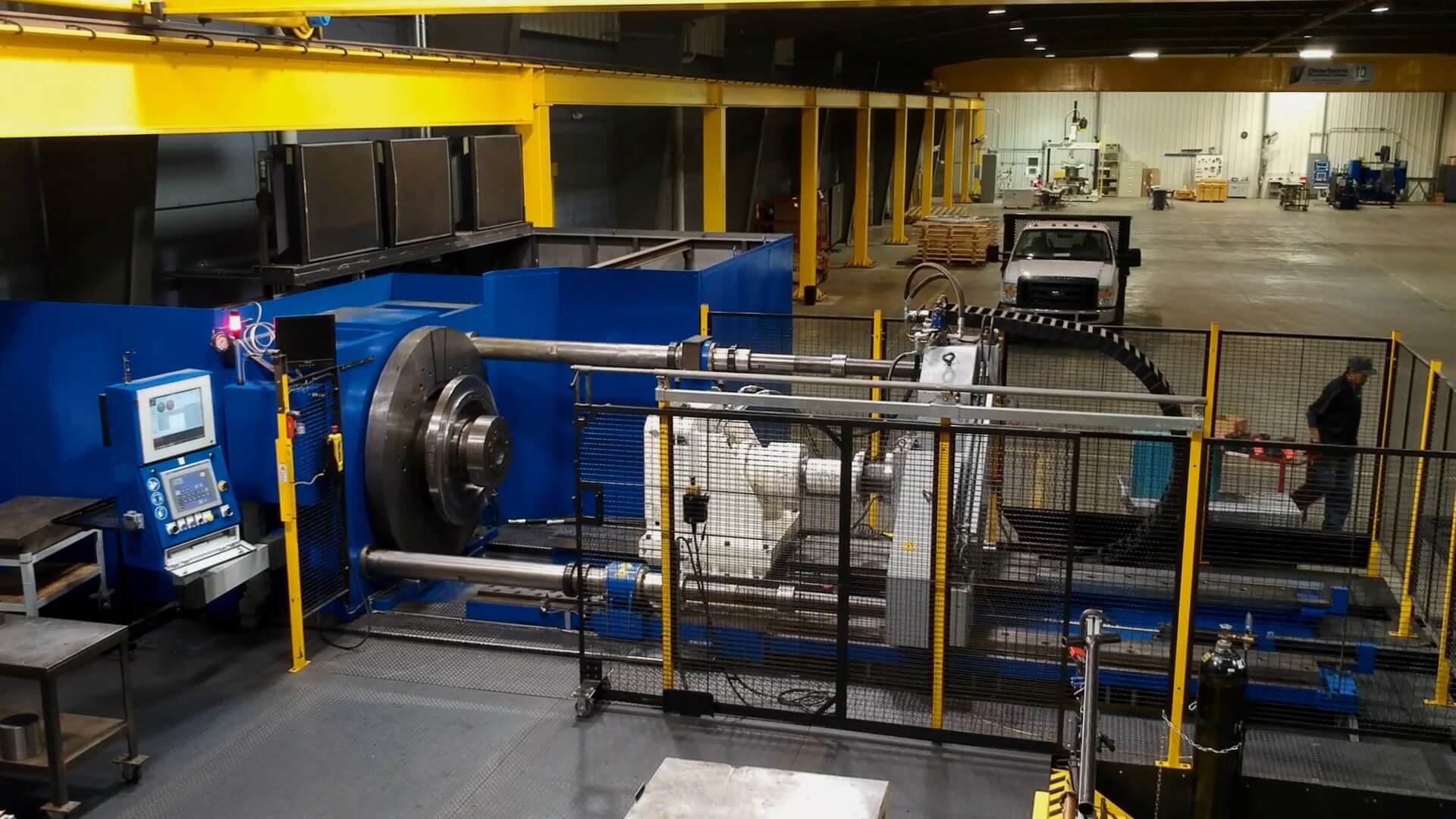

DIRECT DRIVE - MTI

The legacy form of Rotary friction welding, Direct Drive, offers the perfect solution for applications such as axles, piston rods, drill pipe, and more.

Pictured above is MTI’s 15-ton dual spindle machine.

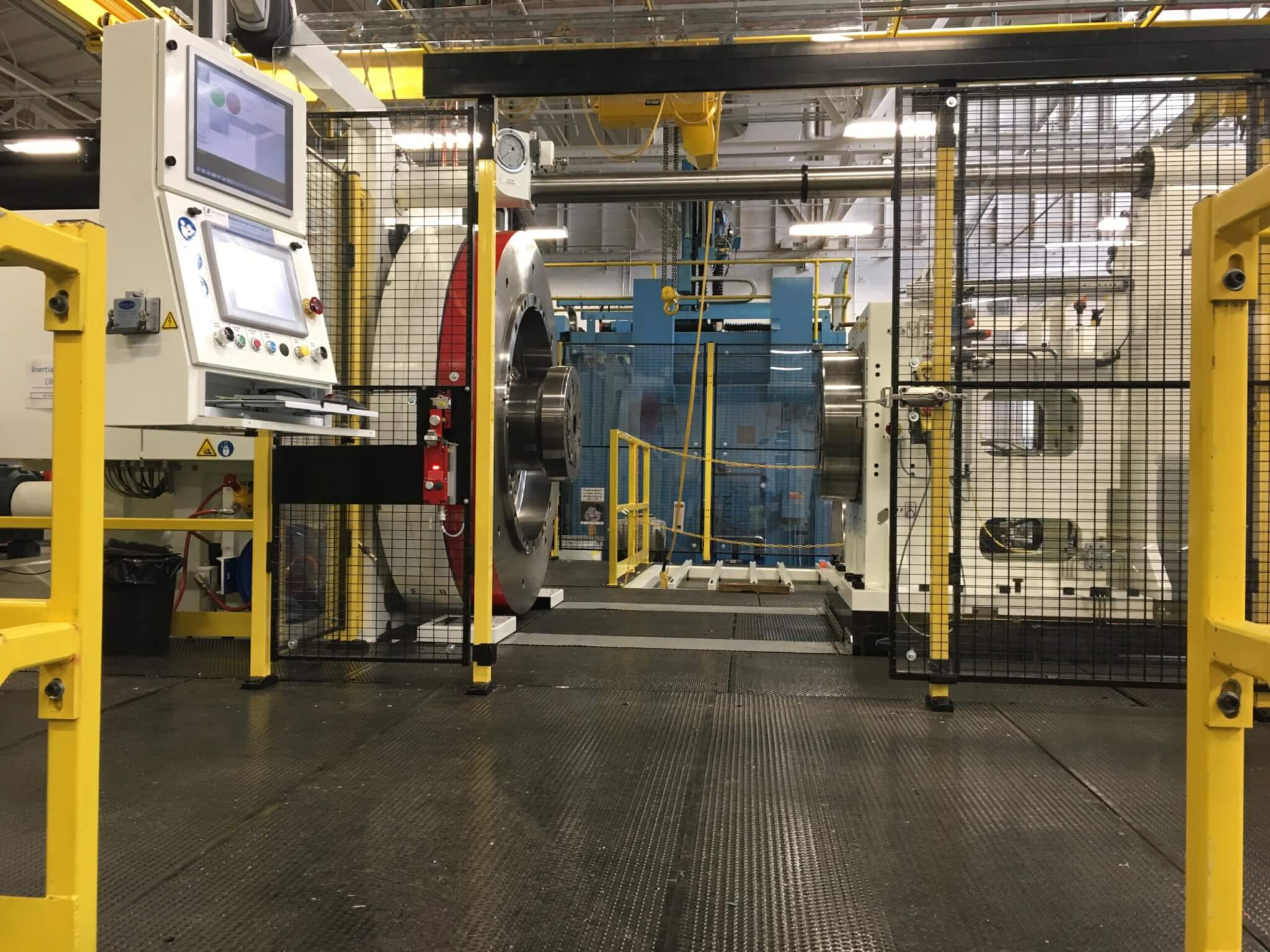

INERTIA

Inertia friction welding is well-suited for large Rotary friction welding applications, such as Aerospace components.

Pictured above is MTI’s M120 Inertia machine.

DIRECT DRIVE - FWT

Friction Welding Technologies Pvt. Ltd. is a Direct Drive Friction Welding company recently introduced into the MTI Group. FWT machines range in size from 6 to 125-tons, offering solutions for a range of Rotary applications and are fully supported by MTI Welding Technologies for Service and Spares.

MTI and FWT’s 3-ton Direct Drive machine.

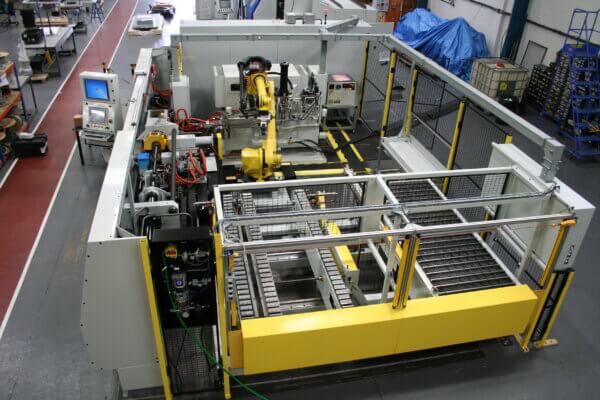

HAVE A NEED FOR AUTOMATION?

MTI not only offers a full range of friction welding machines but also a comprehensive range of semi and fully-automated solutions to accompany our machines. At MTI, our goal is to provide the next generation of autonomous integrated welding systems leveraging our process knowledge and the latest in technology innovation.

With a focus on customised, low-risk configurations, we design and build a range of both Robotic and Gantry solutions to help you find the best automation solution for your product or facility. If you have a preferred supplier for automation or Robotic Equipment, MTI can incorporate these into the machine cell to offer maximum continuity that delivers enhanced quality, productivity, and ROI. Visit our automation page on our North American website for more information.

DOUBLE-ENDED FRICTION WELDING MACHINES

MTI also provides a range of Double-ended friction welding machines. These machines can be fully automated using a combination of Gantry or Robotic load and unload systems. Our Double-ended Rotary machines range from 15 to 180-tons, all designed around our customers’ specifications and preferences.

MTI Double-ended machines are capable of maintaining an orientation to ± 1.5 degrees, coupled with a length control of ± 1mm and a consistent TIR of 0.15mm.

MTI ROTARY FRICTION WELDERS

| Direct Drive | |||

| Machine Type | Max Forge Force (kN) | Max Weld Area (sq mm) | Max Part Diameter solid |

| 5 | 60 | 387 | 22 |

| 15 | 150 | 967 | 35 |

| 25 | 250 | 1613 | 45 |

| 30 | 300 | 1935 | 49 |

| 45 | 450 | 2903 | 60 |

| 60 | 600 | 3871 | 70 |

| 80 | 8000 | 5161 | 81 |

| 100 | 10000 | 6451 | 90 |

| 125 | 12500 | 8064 | 101 |

| 150 | 15000 | 9677 | 111 |

| 200 | 20000 | 12903 | 128 |

| 250 | 25000 | 16129 | 143 |

| 300 | 30000 | 19355 | 157 |

| Inertia | |||

| Machine Type | Max Forge Force (kN) | Max Weld Area (sq mm) | Max Part Diameter solid |

| M60 | 40.03 | 258 | 18 |

| M90 | 57.82 | 368 | 22 |

| M120 | 124.54 | 803 | 32 |

| M180 | 355.80 | 2290 | 54 |

| M220 | 578.2 | 3729 | 69 |

| M250 | 889.6 | 5732 | 85 |

| M300 | 1112 | 7774 | 95 |

| M320 | 1556.8 | 10044 | 113 |

| M400 | 2668.8 | 17218 | 158 |

MTI US

MTI US  FWT

FWT PROSPOT

PROSPOT