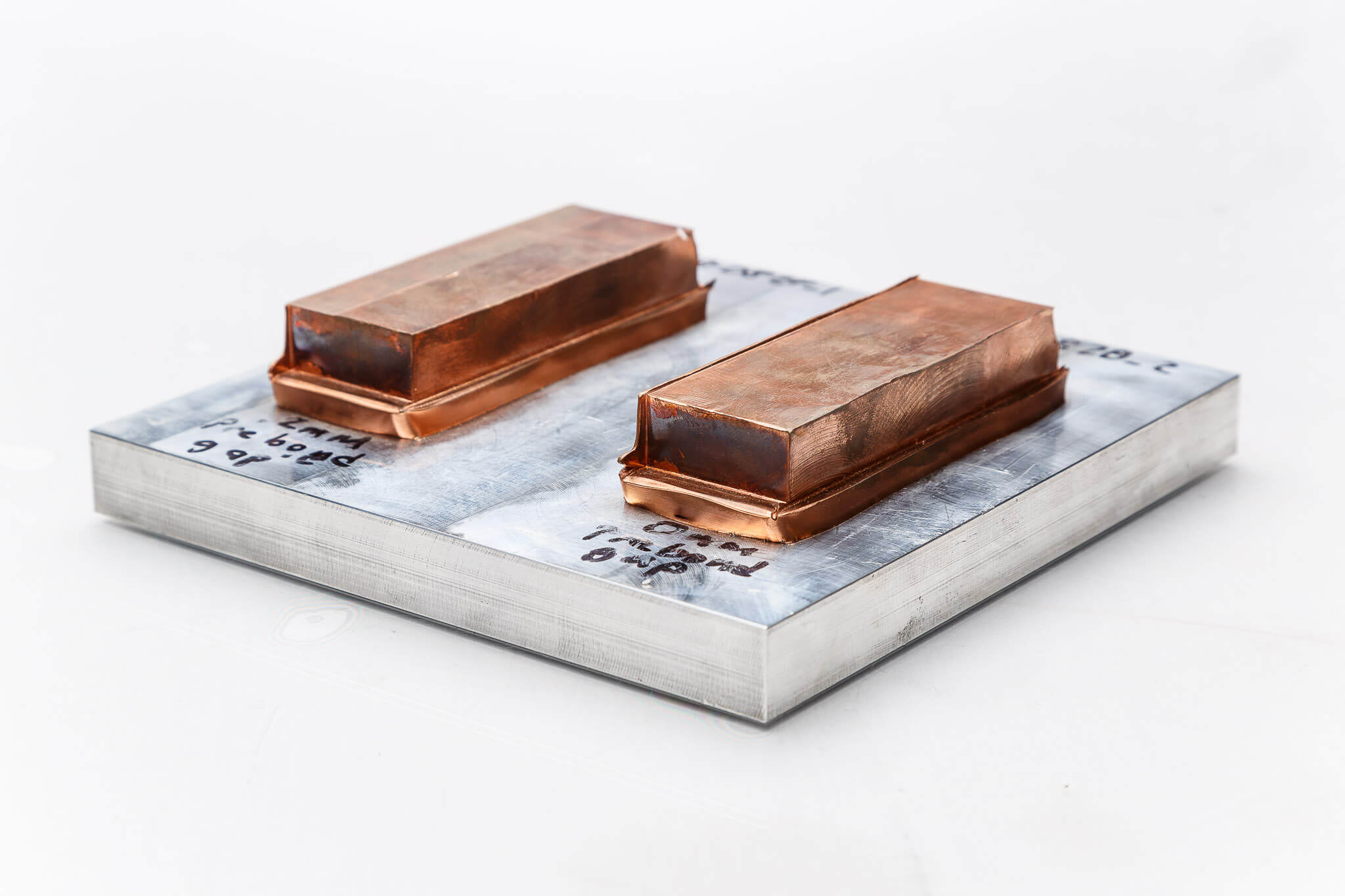

Bi-metallic application linear friction welding of copper alloy block to aluminum plate

All our parts have a story behind them. Explore sample parts below to uncover applications, materials, technology and geometrical fittings that might be right for your next project.

Bi-metallic application linear friction welding of copper alloy block to aluminum plate

Bi-metallic application linear friction welding of copper bars to aluminum plate top angle view

Linear friction welding of all shapes of parts

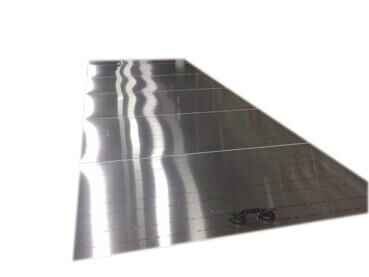

Larger custom aluminum sheet sizes created by friction stir welding from smaller stock pieces

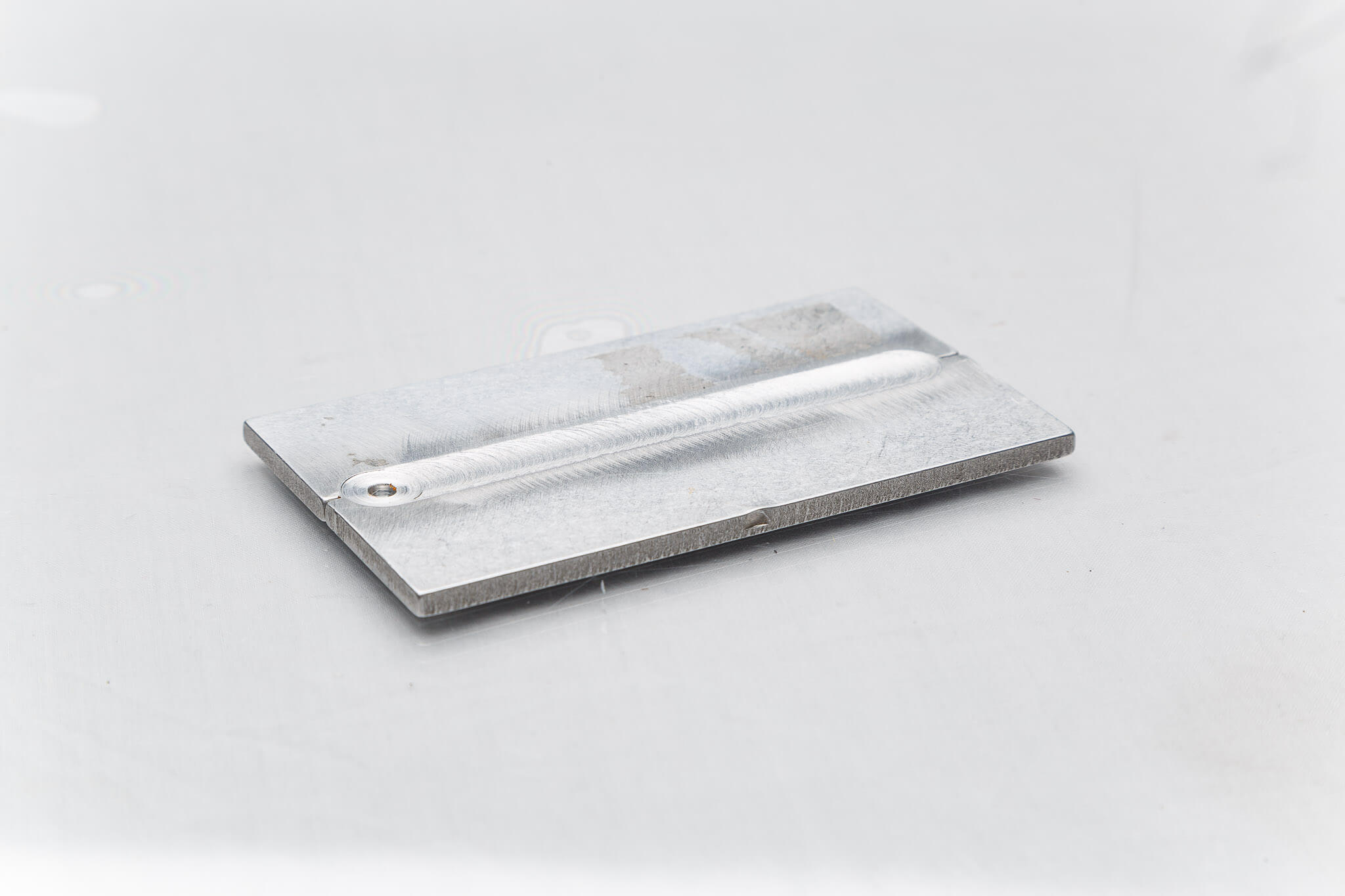

Top view - friction stir welded MTI business card .100" thick aluminum plate

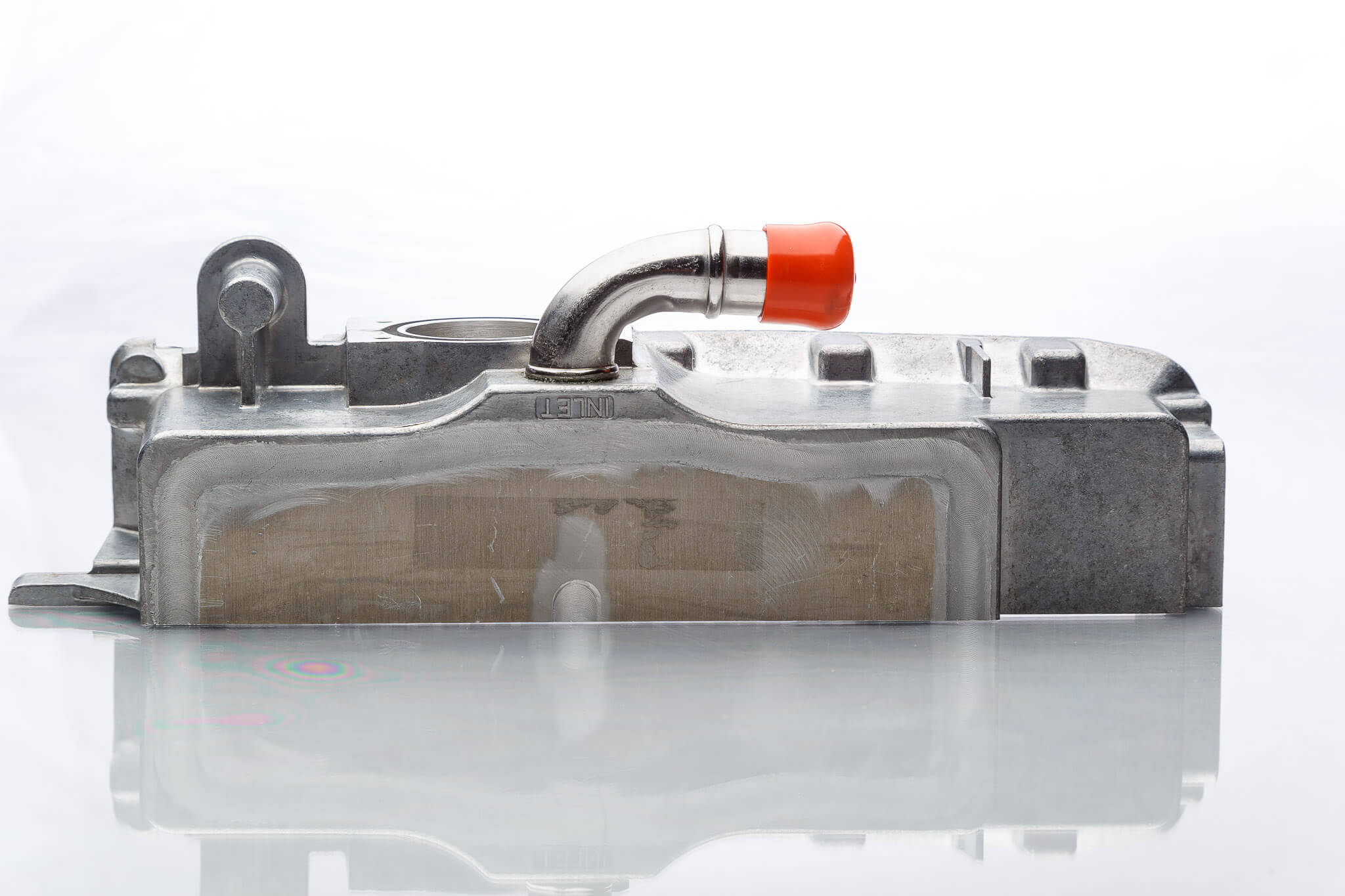

Section view of hybrid vehicle aluminum plate welded to cast aluminum heat exchanger box for a water tite seal. FSW weld path on plate is facing up.

4' section view of joining of multiple aluminum extrusion panel sections up to 50' long via dual weld head (upper & lower) welds

Tailor welded blanks top view -1mm and 2mm thick aluminum sheets jointed prior to stamping. Used for vehicle lightweighting. Heavier 2mm material is deployed in crtical form support areas

Multiple pieces of High Strength Steel Alloy joined in a single friction stir pass for low heat input sheet joining (reducing distortion)

Drive shaft sectioned part front view - tool exit hole shown -lightweighting vehicle while maintaining or increasing durability

Welded machine tool spindle blank. Replaces costly forging.

MTI UK

MTI UK  FWT

FWT