Friction welding solutions for the Automotive industry

From our early days working for Studebaker Automotive to today, our extensive experience in automotive welding solutions is evident in the enormous variety of parts our machines produce. Those applications include stabilizer bars, engine valves, pistons, drive shafts, transmission gears, turbochargers, bumper shocks, suspension components, steering components, water pumps, axles, air bag inflators, camshafts, U-joints, and so many more. Friction welding may be fully integrated into automated production lines to handle this industry’s high volume demands.

Is the Double Ended Axle Machine right for your company?

BRING IT ALL TOGETHER with MTI’s friction welding for axles and housings.

How is MTI solving current problems in the automotive manufacturing industry?

We’re excited to share with you a NEW technical white paper about the advantages of friction welding in the automotive industry. In recent years, the automotive industry has faced an increasing number of challenges. Customers in the automotive industry demanded a machine that could keep product costs low, meet rigorous standards, and keep up with changing trends. Tier 1 and Tier 2 automotive suppliers were looking for a solution that could stand up to harsh environments but also help them achieve their lean manufacturing goals. Get started today and GO ALL IN!

GET THE FREE WHITE PAPER

| Application | Figure 2 of 2 - Transition joint for cryogenic application |

| Materials | Aluminum Alloys |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Driver side airbag inflator - cross-section |

| Materials | Aluminum Alloys |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Passenger side airbag |

| Materials | Aluminum Alloys |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Hybrid passenger side airbag inflator |

| Materials | Aluminum |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Driver and passenger side airbag inflators |

| Materials | Aluminum |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Side-impact airbag inflators |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Figure 1 of 2 Passenger side airbag inflator and cross-section |

| Materials | Aluminum Alloys |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Figure 2 of 2 Passenger side airbag inflator and cross-section |

| Materials | Aluminum Alloys |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Figure 1 of 2 Wheel rim |

| Materials | Aluminum Alloys |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Figure 2 of 2 Wheel rim cross-section |

| Materials | Aluminum Alloys |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Forgings can be welded to barstock, tubes, plates and the like, as shown with these drive shafts |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Experimental aluminum suspension link |

| Materials | Aluminum Alloys |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Experimental chassis component |

| Materials | Aluminum Alloys |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Retainer-differential bearing blank cross-section (left). Bearing housing retainer for transaxle (right). |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Transmission part |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Hollow engine valves for lightweight and liquid-cooled applications |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Bar |

| Application | Flanged Axle |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Experimental hollow automotive rear axle. Tubing welded to hub forging and spline blank. Replaces solid forging for weight reduction. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Bi-metallic engine exhaust valves showing head and stem components, as-welded valve and welded valve with flash removed by shearing. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Automatic transmission output shaft. Stamped steel flange welded to barstock. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Fan shaft bracket assembly. Barstock welded to plate replaces machined forging. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

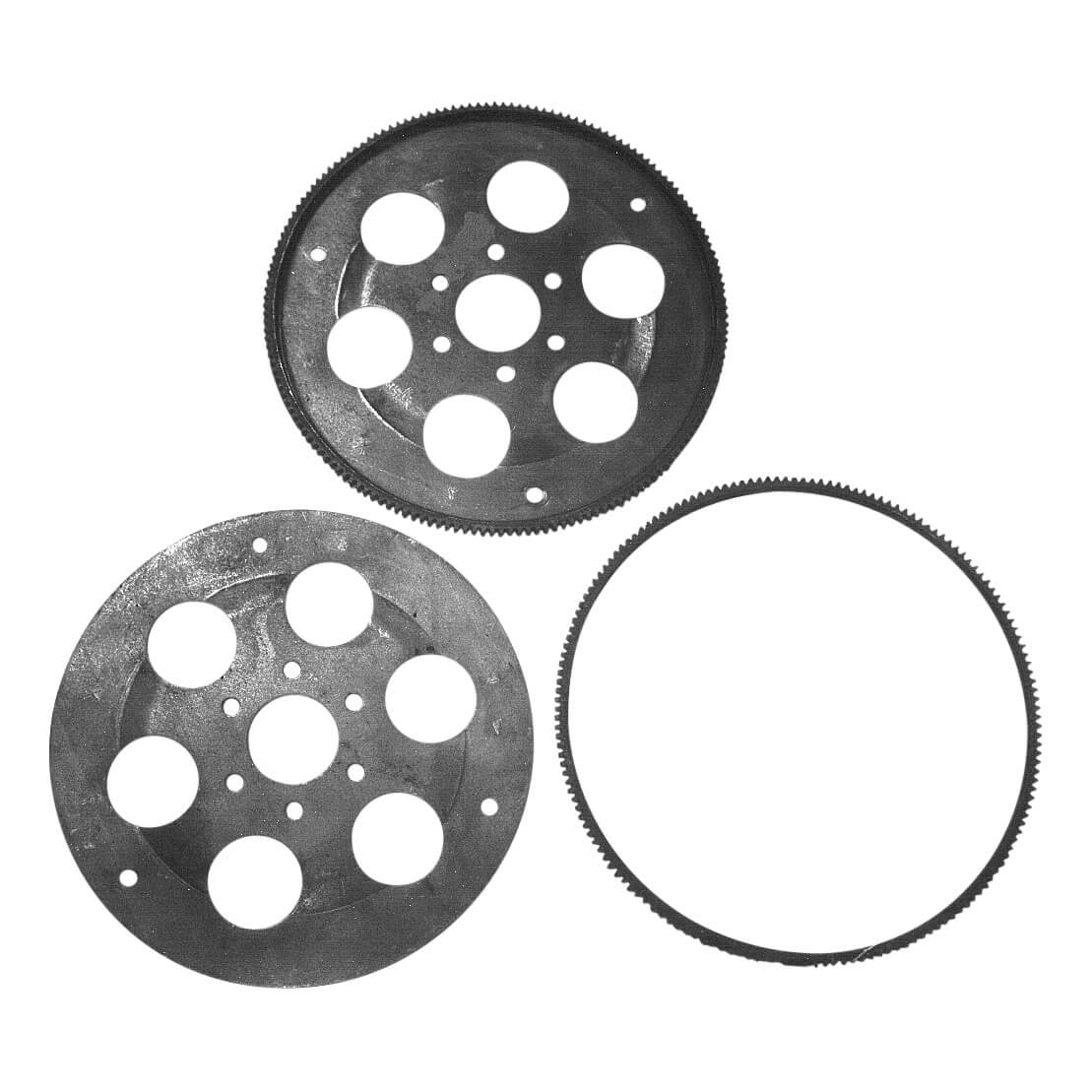

| Application | Rolled ring gear welded to flywheel stamping produces distortion-free flywheel ring gearauto |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Alternator bracket. Barstock welded to plate, replaced forging. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Viscous drive fan shaft couplings replace forgings. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Starter pinion assembly. Sintered steel gear welded to sleeve. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Automotive hydraulic jack. Fabricated from tubing and plate stock. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Cross-section of hydraulic jack showing two tubularwelds which were made simultaneously to the base plate |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Speed selector shaft. Mild steel yoke welded to SAE1045 shaft replaced pinned assembly. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Constant Velocity Joint |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Countersinks. High-speed steel heads welded to mild-steel shanks. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Universal joint assembly with welded extension shaft |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Bar |

| Application | Steering shaft welded to pre-assembled knuckle |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Water pump hub and shaft |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Automotive axle tube |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Bar |

| Application | Rear axle housing tube. Forged tube end welded to tube stock. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Automotive transmission component. Machined tubing welded to cold-formed end. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Electric motor housing and shaft for automotive cooling fan. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Disk |

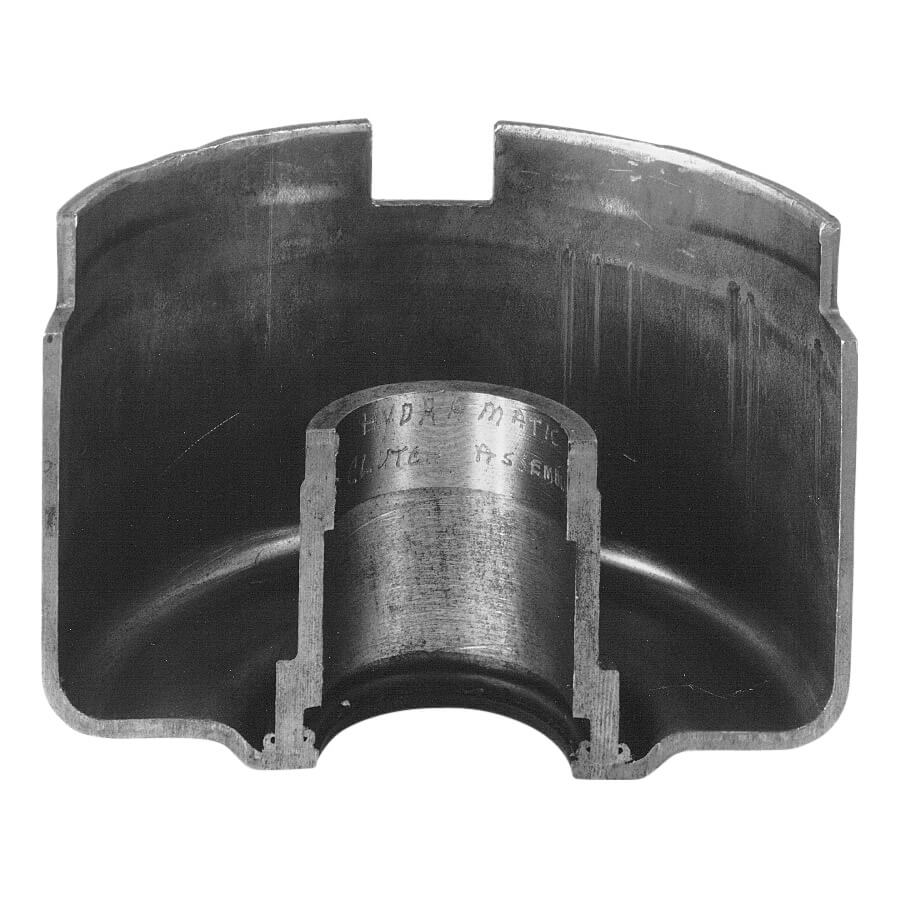

| Application | Figure 1 of 2 Direct clutch drum and hub assembly used in automatic transmissions. Mild steel tubing welded to cold-formed clutch drum. Cross-section. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Disk |

| Application | Figure 2 of 2 Direct clutch drum and hub assembly cross-section. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Torque converter cover. Three mounting nuts welded to cover for mounting of flywheel ring gear. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Torque converter pump |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Clevis |

| Materials | |

| Technology | |

| Geometry | Bar to Bar |

| Application | Worm gear drive shaft |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Drive shaft |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Front wheel drive shaft |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

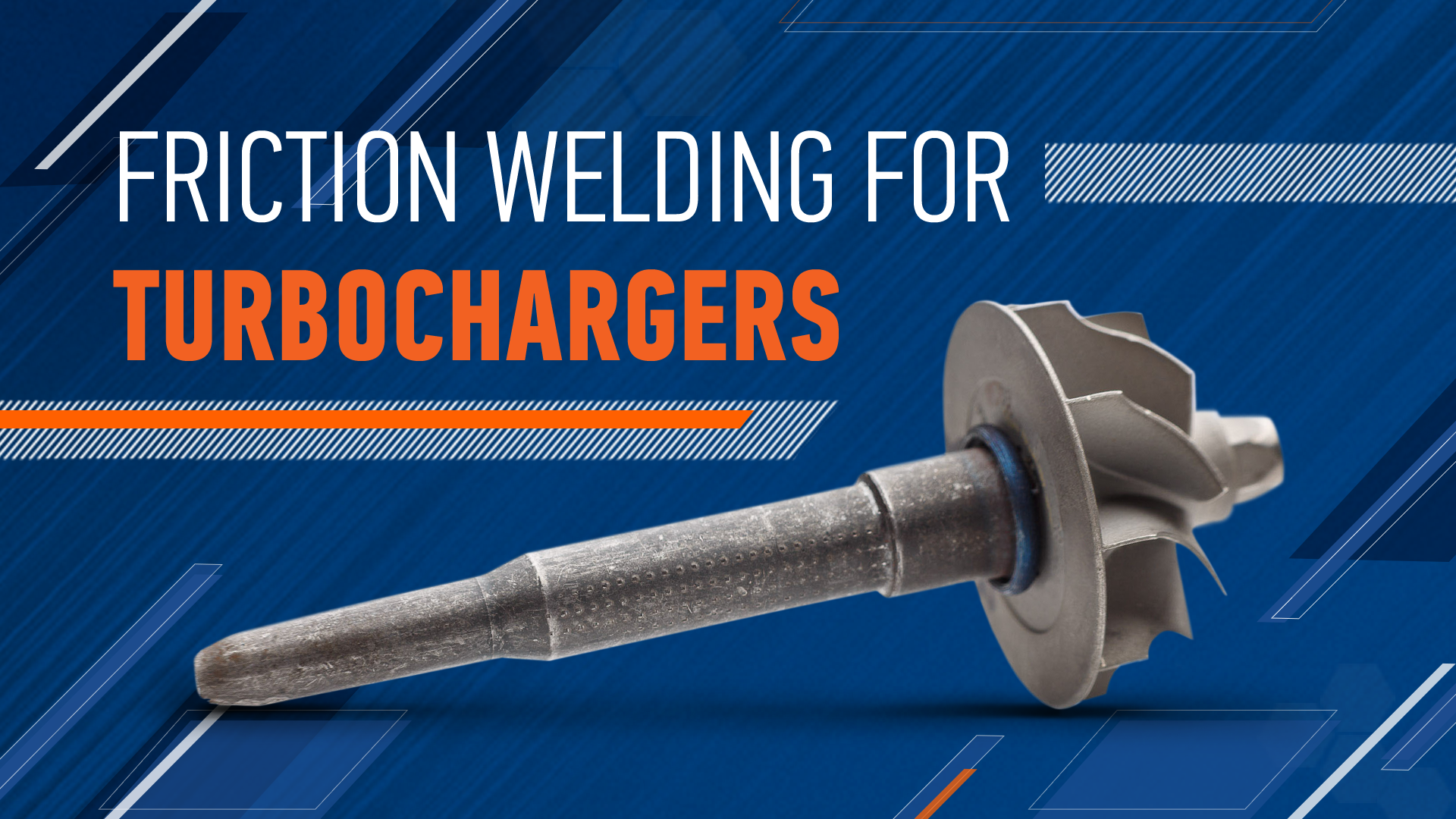

| Application | Turbocharger |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Disk |

| Application | Transmission gear. Finished spiral bevel gear welded to tubular shaft. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Wheel spindle |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Air conditioner accumulator. Aluminum housing. |

| Materials | Aluminum Alloys |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Transmission input shaft |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Brake caliper. Tubing joined to formed caliper. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Disk |

| Application | Drive extension (internal spline one end). |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Front suspension struts |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Sport utility 4x4 interconnecting shaft |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Figure 1 of 2 Stabilizer bars. Tube welded to solid end. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Bar |

| Application | Figure 2 of 2 Welded stabilizer bar cross-section |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Bar |

| Application | Input shaft for automotive transmission. Stamped hub to machined barstock. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Shock absorber base cup. Weld between threaded stud and base cup firmly traps washer in place. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Bumper shocks. Tubing welded to stamping for impact absorbing bumper mounts. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Air conditioner rotor assembly. Outer rotor pole is welded to inner rotor pole then this assembly is welded to pulley blank. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Disk |

| Application | Drive shaft sectioned part front view - tool exit hole shown -lightweighting vehicle while maintaining or increasing durability |

| Materials | Aluminum |

| Technology | Friction Stir Welding |

| Geometry | Lap |

| Application | Tailor welded blanks top view -1mm and 2mm thick aluminum sheets jointed prior to stamping. Used for vehicle lightweighting. Heavier 2mm material is deployed in crtical form support areas |

| Materials | Aluminum Alloys |

| Technology | Friction Stir Welding |

| Geometry | Lap |

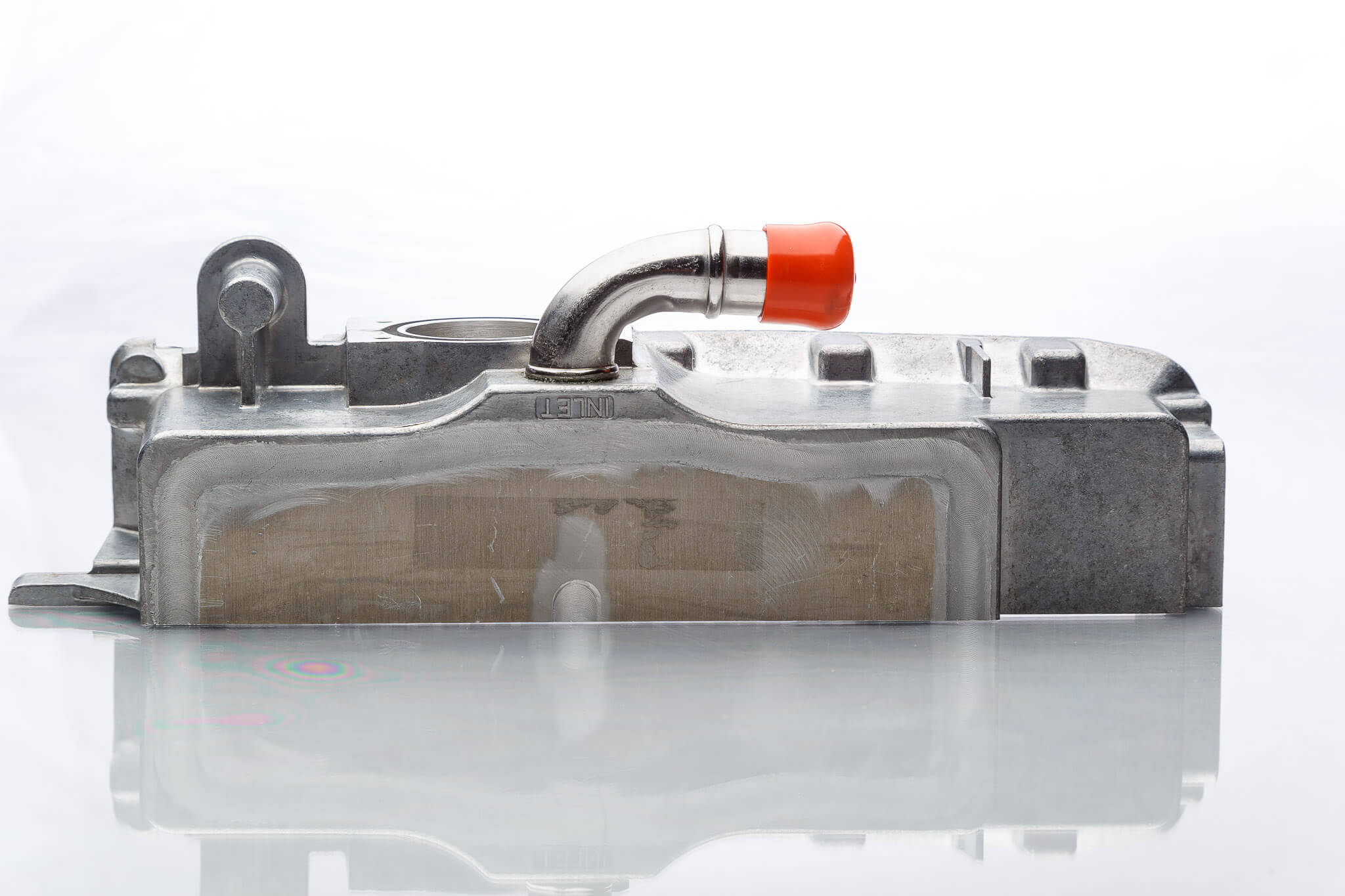

| Application | Section view of hybrid vehicle aluminum plate welded to cast aluminum heat exchanger box for a water tite seal. FSW weld path on plate is facing up. |

| Materials | Aluminum Alloys |

| Technology | Friction Stir Welding |

| Geometry | Lap |

Demand for automotive airbag inflators has stimulated the increase in the number of friction welders manufactured for the automotive industry since the 1980s. That’s because advantages such as a full-penetration weld, as well as its narrow heat-affected zone have made friction welding a key method for joining fully-loaded airbag inflators. The dramatic increase in the volume of friction welding applications and equipment continues to this day. Successful material combinations include aluminum, low carbon steel, and stainless steel alloys.

Explore Our ProcessAre your wheels turning yet?

Let’s talk and bring your idea from concept to completion.

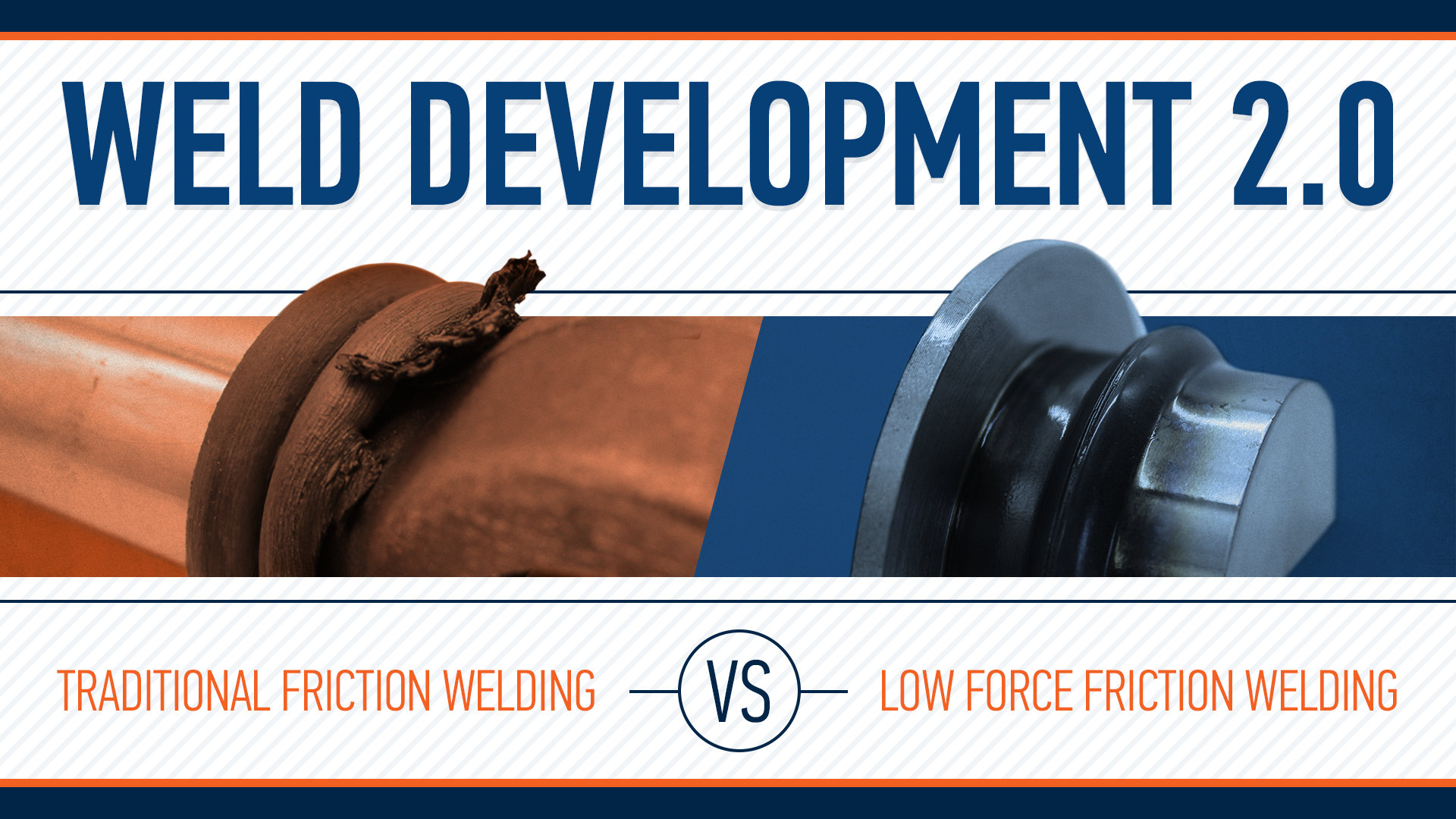

Get the most out of your manufacturing process with MTI's newest Weld Development package.

MTI has added a new tri-mode Rotary friction welding machine to our Manufacturing Services location! Keep reading to learn if its right for your project.

MTI UK

MTI UK  FWT

FWT