Friction welding solutions for the Construction and Agriculture industries

Friction welding is used extensively in the Construction and Agricultural industries because the welds are of forged quality, with a 100% butt joint weld throughout the contact area. This creates a bond strong enough to handle the high stress and torque required of heavy machinery components including hydraulic piston rods, rear axles, and gears.

MTI has extensive experience developing welding solutions for the construction and agricultural industry. Friction welding is used extensively in the agricultural industry because the welds are of forged quality with a 100% butt joint weld throughout the contact area. The bond is strong enough to handle the high stress and torque required of heavy machinery components. These costs can be lowered by replacing expensive, total forged parts with forged end welded to bar or tube stock without a reduction in quality. An example of this is hydraulic piston rods. These have similar-size ends but vary in rod diameter and length. Standardized ends can be welded to the required-size rod, reducing component costs as well as physical inventory requirements.

| Application | Water pump gear |

| Materials | |

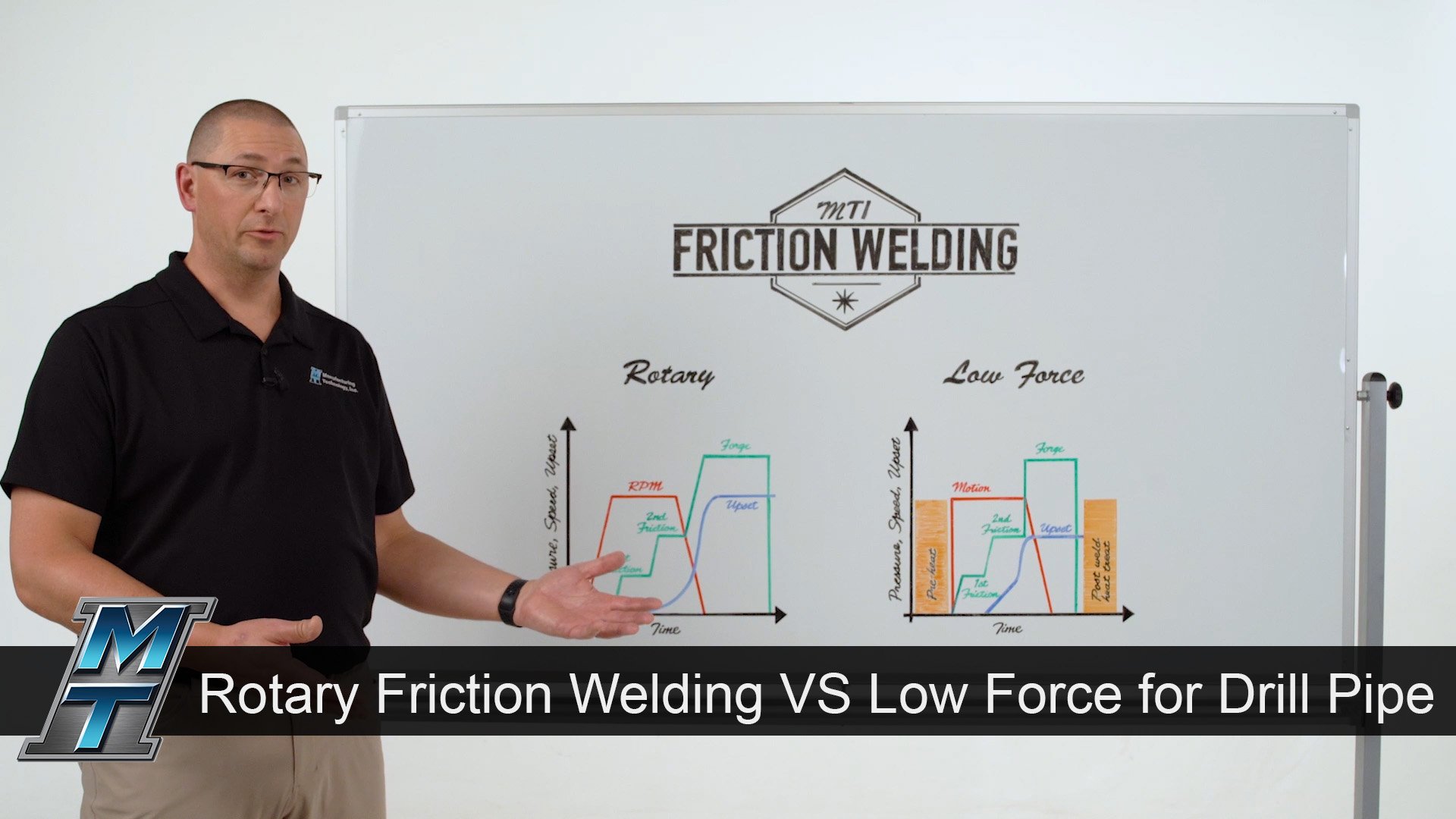

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

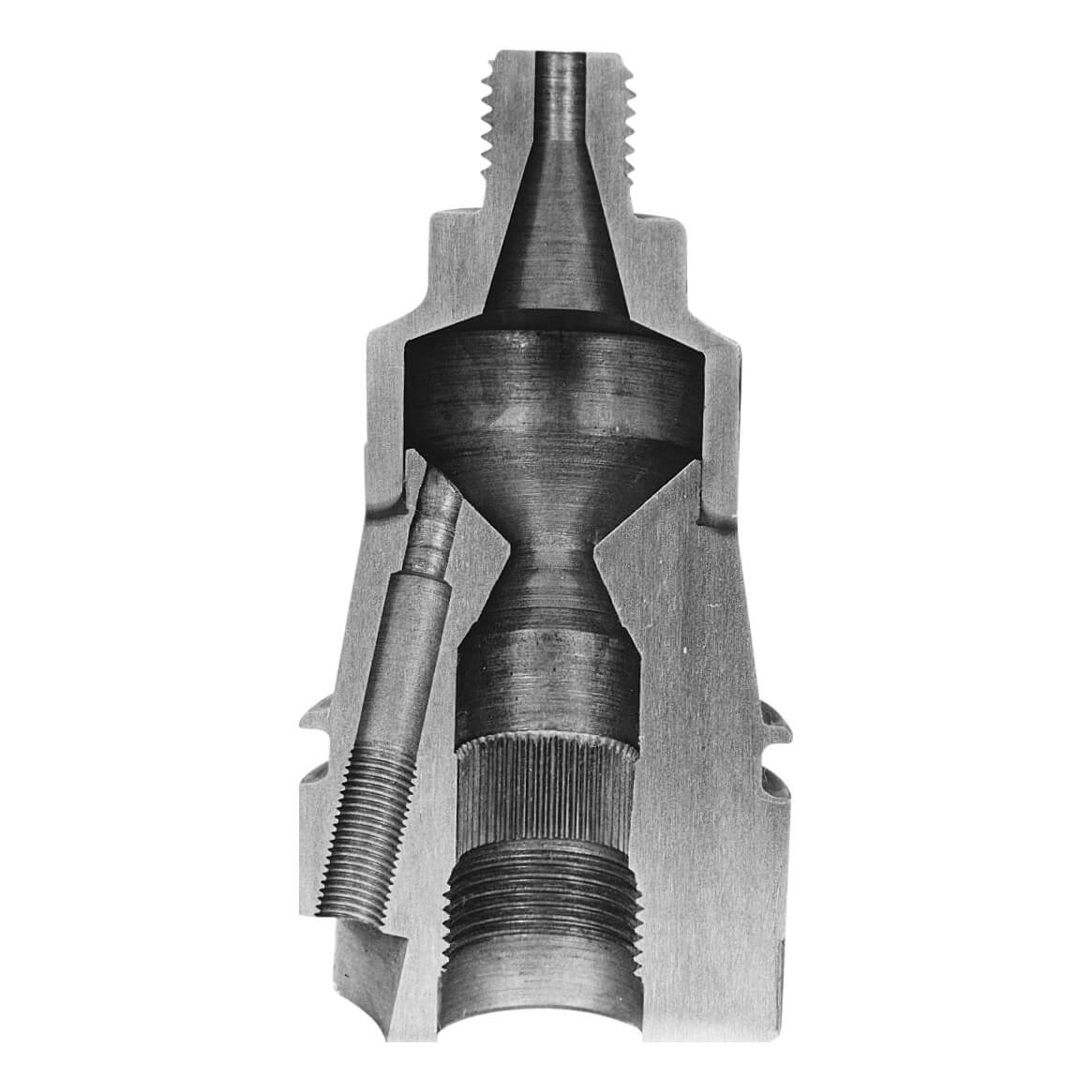

| Application | Diesel engine pre-combustion chamfer cross-section |

| Materials | Steel - Alloys |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Disk |

| Application | Water pump - as welded |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Water pump - finished |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Diesel engine piston |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

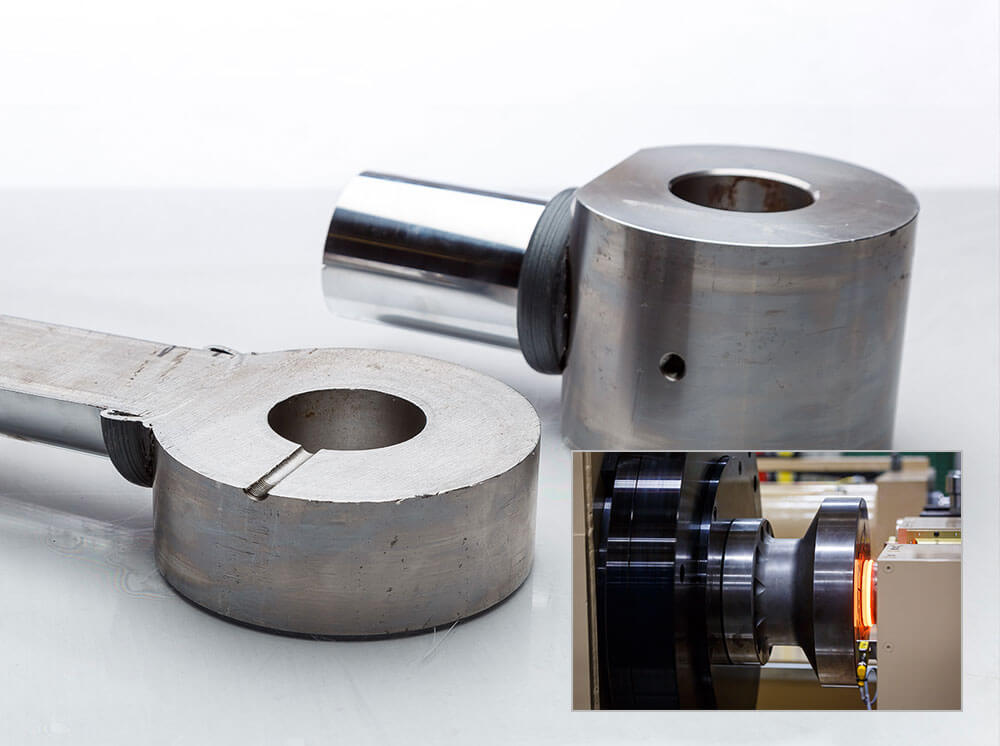

| Application | Track roller. Forged halves welded together to produce track roller assemblies. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Steel-backed, bronze-laminate thrust washers and sleeves welded together to produce track roller bushings. Replaced costly, solid bronze castings. |

| Materials | Copper Alloys |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Rear axles for tractors - 4 inches (101.6 mm) diameter bar stock welded to hub forging |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Truck trailer brake S-cam |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Forged wheel spindles joined to 5 inches (127 mm) diameter - 5 inches (12.7 mm) wall tubing to produce trailer axles. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

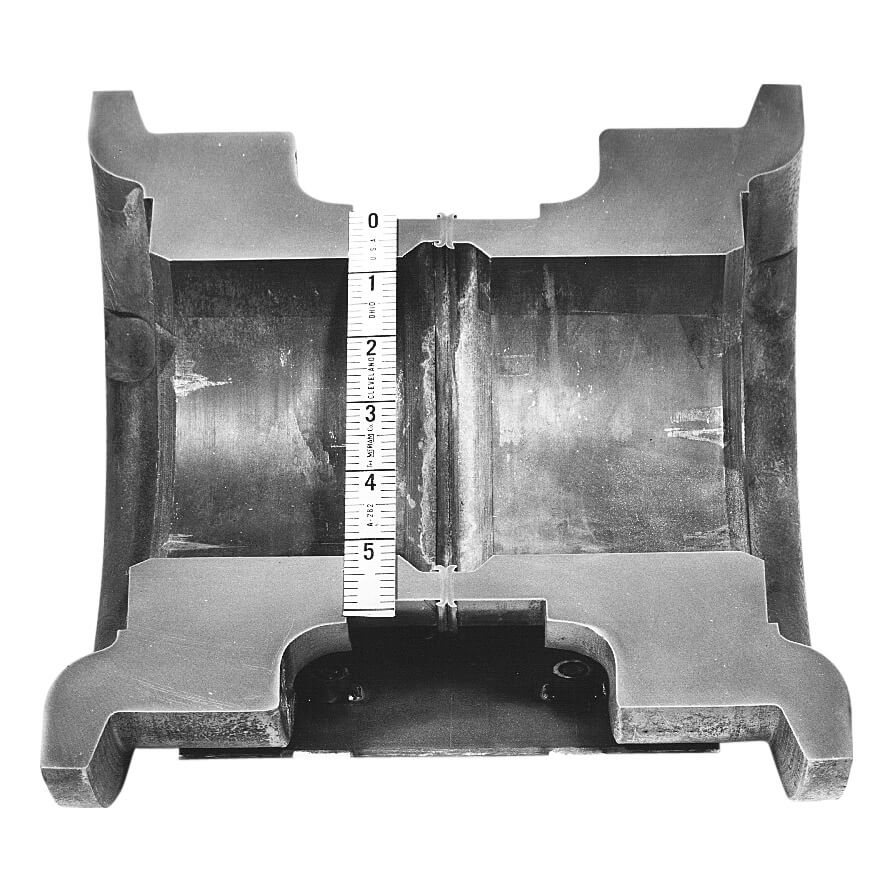

| Application | Power control drive shaft for motor grader. Inertia weldment replaces upset forging (left) which required five straightening operations |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Universal joint clevis |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Bar |

| Application | Front axle yoke shaft for four-wheel-drive vehicles - bar stock to yoke forging |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Pin assembly. Pre-chromed pin welded to retaining plate |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Finished gear welded to clutch drum |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Oil pump gears. Welded bar stock replaces forged blanks. 15% - 30% cost reduction (depending on size and usage). |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Cluster gear. Small finished gear welded to larger gear blank. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Disk |

| Application | Two pre-finished transmission gears welded using precision piloted tooling |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Tube |

| Application | Chain drive sprocket |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Tube to Plate |

| Application | Lift screw. Roll threaded stock cut to length and welded to screw machined ends. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Lift link-ball socket. Forged couplings welded to tubing and barstock. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Truck rear suspension link welded on twin 150 Inertia Welder. Ends are oriented to within ±1° of each other. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Torque rod. Forged eye welded to various barstock lengths. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

| Application | Hydraulic piston rods. Rod eyes cut from heavy-wall tubing welded to pre-chromed bar stock. |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Track adjusting yoke for commercial tracked vehicles |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Hydraulic piston rod |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Plate |

| Application | Bar stock welded to clevis forging for manufacture of large (5 inches (127 mm) diameter and larger) piston rods |

| Materials | |

| Technology | Rotary Friction Welding |

| Geometry | Bar to Bar |

Component costs can be significantly reduced by replacing expensive, totally-forged parts with parts using forged ends welded to bar or tube stock. This can be done without a reduction in quality by using friction welding. For example, the hydraulic piston rods used extensively in construction and agriculture equipment have similar-sized ends, but vary in the rod length and diameter. Instead of stocking expensive forged components in a variety of different diameter and length configurations, we can friction weld standardized ends to the required rod size by using standardized stocked diameters and lengths of bar or tube stock. This reduces component costs as well as physical inventory requirements. Other applications include front axle yoke shafts, rear axles, drive shafts, and gears.

Explore Our Process

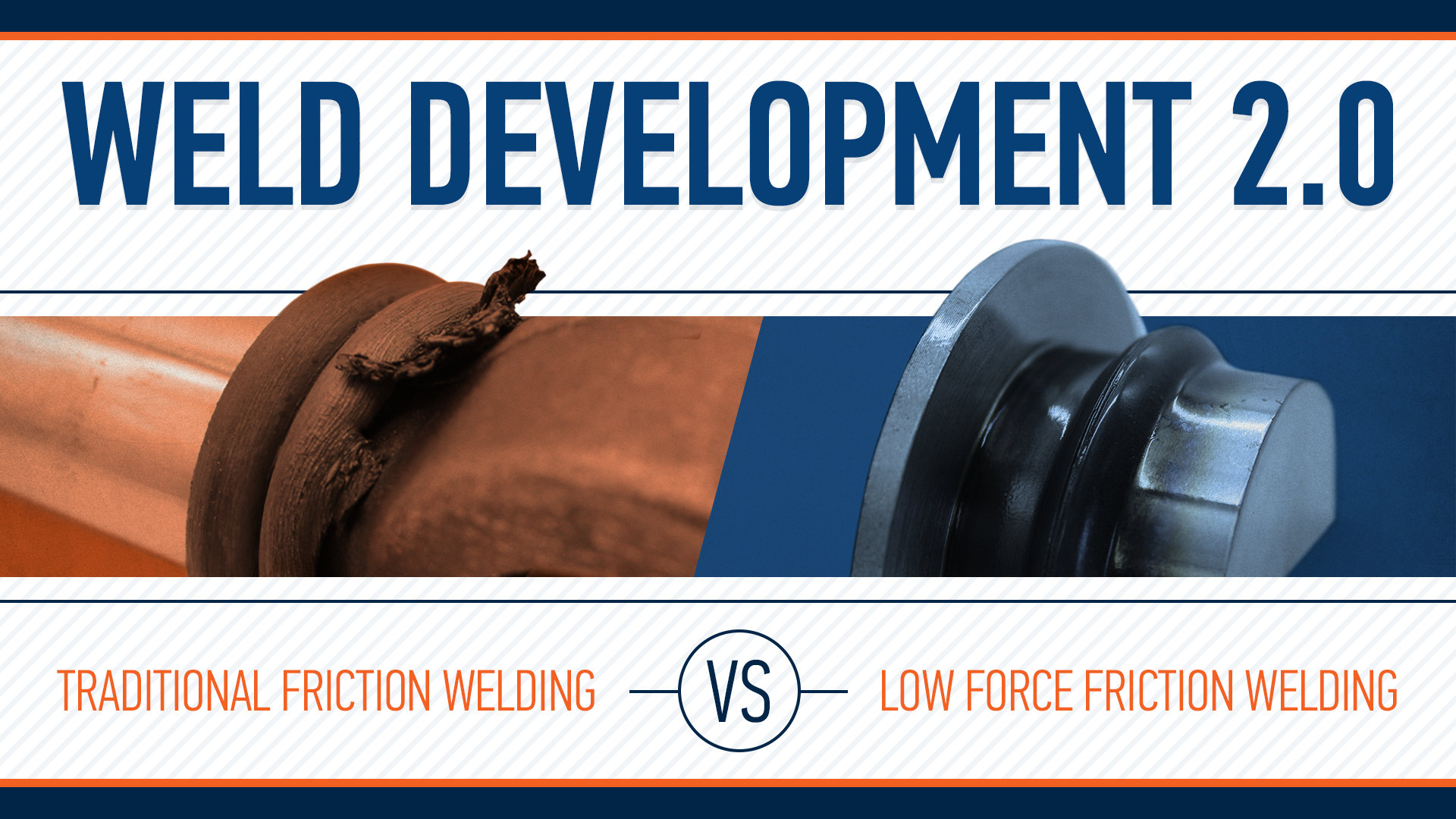

Get the most out of your manufacturing process with MTI's newest Weld Development package.

MTI has added a new tri-mode Rotary friction welding machine to our Manufacturing Services location! Keep reading to learn if its right for your project.

MTI UK

MTI UK  FWT

FWT